Thingiverse

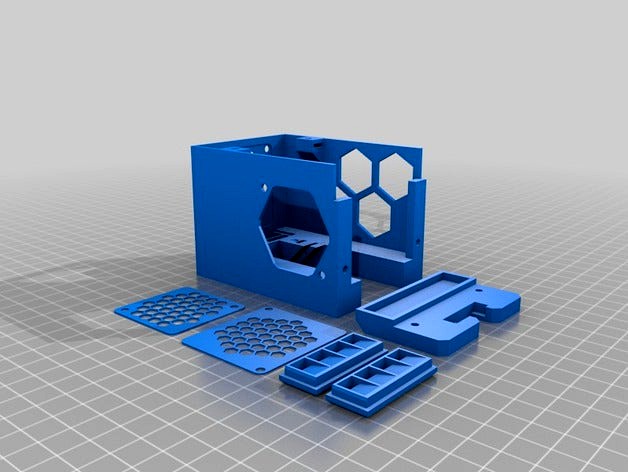

Anycubic i3 Mega partfan monstrosity by BETLOG

by Thingiverse

Last crawled date: 3 years ago

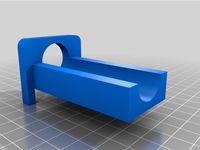

Boxy, but good (enough).

Includes a part that is effectively a remix of: https://www.thingiverse.com/thing:2479809

Borrows dimensions between fixing bolts from: https://www.thingiverse.com/thing:2457516

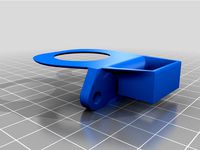

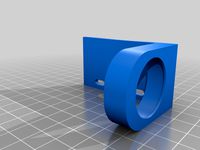

This is an attempt to get partfan coverage from both/all sides, while retaining the original plate mount to the bearings. After several attempts I gave up in disgust with the quest to design something elegant, and just settled for monstrous and temporary: I am a little bit over trying to modify the mega's existing hotend, so this is simply a temporary means of getting better part cooling while I print components for an entirely different printer.

I may eventually revise this later, but it will likely be in a version that completely replaces the megas hotend compartment right back to the X carriage bearings.

It's not pretty, and despite having a COD LED inside it to illuminate the nozzle it's almost impossible to see underneath the ducts anyway, and the LED reaaaaaly needs a trimpot to turn the light down a little. So consider the COB LED slot completely optional. I also soldered the connections to it so they exit towards the leds light emitting surface, so the slots I allowed for wiring to exit may not be big enough for your standard lazily soldered fat blobs of solder and a wire direction change... maybe, maybe not.

The top bolt on the partfan doesnt fit, due to an oversight, so mine runs with it missing.

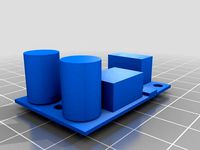

LED COB 26x16mm has a heatsink stuck to it's metal side:

heatsink 14x14x6mm (7x1mmVanes, typically sold in combination with an even smaller one for use on raspberry pi)

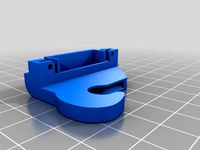

The partfan outlets just click in, helps if you put the short end that's closest to the actual partfan in first, and then force the further edge in last.

No supports, bridging sucks a bit on the partfan outlets, but it doesn't create enough surface roughness to pull the airflow onto the heatsink, so it's ok. You could try separating them from the other parts, flipping them, use supports, and make the airflow surface nice and smooth by printing it as the top face. But I didn't bother.

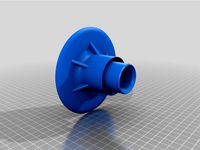

The partfan is a 5015 blower, some are stronger than others. I picked the strongest I had.

The heatsink fan is still the stock 4010

None of the nuts require a print-pause, but it is designed for square M3 nuts... which you may not have. Gluing in a hex nut would also work. I use glue to lightly tack several of them in just to make assembly easier.

PLA, 0.4mm nozzle, 20% infill ... pretty standard (not really important)

1.2mm walls (IS important; or your bridging will suck and all of the basic design assumptions are for that thickness)

It's annoyingly close to the print, and ugly.. but it is a slight partfan improvement.

dealwithit.jpg

Includes a part that is effectively a remix of: https://www.thingiverse.com/thing:2479809

Borrows dimensions between fixing bolts from: https://www.thingiverse.com/thing:2457516

This is an attempt to get partfan coverage from both/all sides, while retaining the original plate mount to the bearings. After several attempts I gave up in disgust with the quest to design something elegant, and just settled for monstrous and temporary: I am a little bit over trying to modify the mega's existing hotend, so this is simply a temporary means of getting better part cooling while I print components for an entirely different printer.

I may eventually revise this later, but it will likely be in a version that completely replaces the megas hotend compartment right back to the X carriage bearings.

It's not pretty, and despite having a COD LED inside it to illuminate the nozzle it's almost impossible to see underneath the ducts anyway, and the LED reaaaaaly needs a trimpot to turn the light down a little. So consider the COB LED slot completely optional. I also soldered the connections to it so they exit towards the leds light emitting surface, so the slots I allowed for wiring to exit may not be big enough for your standard lazily soldered fat blobs of solder and a wire direction change... maybe, maybe not.

The top bolt on the partfan doesnt fit, due to an oversight, so mine runs with it missing.

LED COB 26x16mm has a heatsink stuck to it's metal side:

heatsink 14x14x6mm (7x1mmVanes, typically sold in combination with an even smaller one for use on raspberry pi)

The partfan outlets just click in, helps if you put the short end that's closest to the actual partfan in first, and then force the further edge in last.

No supports, bridging sucks a bit on the partfan outlets, but it doesn't create enough surface roughness to pull the airflow onto the heatsink, so it's ok. You could try separating them from the other parts, flipping them, use supports, and make the airflow surface nice and smooth by printing it as the top face. But I didn't bother.

The partfan is a 5015 blower, some are stronger than others. I picked the strongest I had.

The heatsink fan is still the stock 4010

None of the nuts require a print-pause, but it is designed for square M3 nuts... which you may not have. Gluing in a hex nut would also work. I use glue to lightly tack several of them in just to make assembly easier.

PLA, 0.4mm nozzle, 20% infill ... pretty standard (not really important)

1.2mm walls (IS important; or your bridging will suck and all of the basic design assumptions are for that thickness)

It's annoyingly close to the print, and ugly.. but it is a slight partfan improvement.

dealwithit.jpg

Similar models

thingiverse

free

CR10S-Fan-Shroud by ESEAone

...ng the airflow. since the top edge was curved around the nozzle with no support i suggest putting temporary support in this area.

thingiverse

free

50 watt COB LED wafer cover

...diation cooling.

the second file has a little more of a pocket for the nuts so that the cover pushes back closer to the heatsink.

thingiverse

free

80mm LED Ring Holder for Anycubic I3 Mega by ThomasMielke

...upport. the 80mm led ring then can be clipped in from above. the screws from the hotend fan can be used to fix at the hotend box.

grabcad

free

Anycubic i3 mega Hotend fan box (also Mega-S, Mega-X, Full Metal, BLTouch & E3DV6 versions)

...ews - no need to buy new parts.

https://www.prusaprinters.org/de/prints/47884-anycubic-i3-mega-hotend-fan-box-also-mega-s-mega-x

thingiverse

free

Hook to hang a 10W LED from a joist by jdh30

...ith 10w leds mounted on them. now our whole garage is lit bright and white. i might use the form 1+ to 3d print some diffusers...

thingiverse

free

Anycubic I3 Mega-S Extruder Filament Input Nozzle by eisenfliege

...wn. best print it with tpu.

it is only for the mega-s extruder - maybe some other anycubic printer models use the same extruder.

thingiverse

free

10w cob mount by johanhoahm

...und led cob with heatsink to my mini talon,

but if just use hot glue, the heat from led will make it loose.

so i make this mount.

3dwarehouse

free

PIN heatsink

...pin heatsink

3dwarehouse

pin heatsink for cob led

thingiverse

free

Anycubic I3 Mega LED Hotend Cover Low Noise by FiddlyFiddler

...losed version without the cutouts included. the freecad files are also available, so you can customize or remix the cover easily.

thingiverse

free

Cr10 Led Light Bar by Phillipnielsen

...ter being on :-)

works in conjunction with other types of hotend fan shrouds, not too good the original. happy printing, cheers !

Partfan

thingiverse

free

GEEETECH A10-M_Luftkanal Partfan by DDDUM

...geeetech a10-m_luftkanal partfan by dddum

thingiverse

partfan kanal mit led

thingiverse

free

Dual 30mm fan mount for Monoprice Select Mini

...i have added two stabilizer beams to support the partfan to minimize vibrations. additionally, the partfan threads have been...

thingiverse

free

Sapphire Pro/Plus DirectDrive by erdna1281

...with an orbiter extruder and a mosquito hotend. as partfan i used original 4010 blowers and the hotendfan is...

thingiverse

free

combo 40mm Fan Shroud by BETLOG

...shroud by betlog thingiverse combo 40mm fan shroud - partfan and heatsink fan i'm using it on this: https://www.thingiverse.com/thing:2864216...

thingiverse

free

Quick Fit Carriage System - BETLOG VERSION by BETLOG

...i recently began using this: https://www.thingiverse.com/thing:3047484 instead of the partfan components included in this (quickfit) thing as they are...

thingiverse

free

CR10S PRO light weight head, no sensor, microswitch by OZ2CPU

...need the cr10-cylinder-sensor-simulator incase you remove the original sensor. cr10-partfan press in 2 x m3 nuts all brackets will...

grabcad

free

Tevo BW Fan Shroud

...cooler 40mm fan. prints best in petg - no partfan pla will be...

3dwarehouse

free

Titan Aero (Clone) for Tronxy X5SA

...only 3 parts to print. i use the original partfan otherwise you found in the skp file a bigger...

Betlog

thingiverse

free

dummy - barrel connector 5.5mm female by BETLOG

...- barrel connector 5.5mm female by betlog

thingiverse

a reference object i needed to make for "does it fit?" purposes.

thingiverse

free

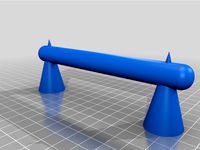

DUMMY DC12V 40mm 4500RPM Brushless Fan Blower by BETLOG

...an blower by betlog

thingiverse

dummy/mockup/reference model of a

dc12v 40mm 4500rpm brushless fan blower

like the images shown.

thingiverse

free

Drill_bits_cylindrical_case-BETLOG-002 by BETLOG

...precise than needing to add 0.45 to 0.48...divided by two (0.225 to 0.24) to everything....0.4 divided by 2 is 0.2... and easier.

thingiverse

free

Z Leadscrew Rod Stabilizer - Flyingbear P902 by BETLOG

...e loud squeaking it makes when moving the z axis large distances.

connects to the 2020 frame by the usual m4 bolts and hammernuts

thingiverse

free

dummy - regulator 9-35V to 5v 5A by BETLOG

...e for "does it fit?" purposes.

2017-07-28 - replaced. previous version holes and width were incorrect enough to matter.

thingiverse

free

tool-capsuleFiller by BETLOG

...is to work reliably.

designed for size #00 caps.

requires 4x 0.8x10x15mm springs https://www.aliexpress.com/item/32963259463.html

thingiverse

free

Raspberry Pi Zero Case - BETLOG version by BETLOG

...precise than needing to add 0.45 to 0.48...divided by two (0.225 to 0.24) to everything....0.4 divided by 2 is 0.2... and easier.

thingiverse

free

calibration - quick - support angle by BETLOG

...el is small to print fast, and simulate almost worst case scenario where heater is always in fairly close proximity to the print.

thingiverse

free

fan guard - 60mm by BETLOG

...lades will almost always be the last time.

as always; assumes a 0.4mm nozzle. layer height is fairly irrelevant, but i used 0.3mm

thingiverse

free

BladeScraper by BETLOG

...t;hold" the blade so once you get it under the print yo can remove the block and just move the blade around under the print.

Monstrosity

thingiverse

free

Stitched Monstrosity

... monstrosity

thingiverse

a stitched monstrosity.

you can support me on https://www.patreon.com/schlossbauer if you like my work.

thingiverse

free

Monstrosity hand by Dantego

...and or like a decorative object.

she can be print in once print. but you can slice it with a software like netfabb / meshimixer.

thingiverse

free

yodapus AKA a monstrosity

...yodapus aka a monstrosity

thingiverse

i have created a monster... just because i was bored...

thingiverse

free

Five Headed Monstrosity by ASLLEXICON

...https://brave.com/tod573

visit my website: https://starlabs3d.com

my youtube: https://www.youtube.com/c/toddolsen

see video below

thingiverse

free

RPI plus 12V Cooling Monstrosity

...mean-looking cooling tower for the raspberry pi 3b+, primed for overclocking, and ready for raw data, or just running octo-print.

thingiverse

free

Gloomhaven Jaws of the Lion: Rat Monstrosity by VirtuallyJason

...ttps://patreon.com/virtuallyjason. if you appreciate my work and have a few dollars to spare each month, please consider joining!

thingiverse

free

Angler Fish Monstrosity - Tabletop Miniature by M3DM

...ts here! i also offer a learn to 3d model package for aspiring 3d sculptors.

no errors in meshmixer, so it should be good to go!

thingiverse

free

Vase Monstrosity by barty3d

... out the assembly modeling and if i like that i will go ahead and buy. renders are in bryce 3d (green glass) and keyshot (wood).

thingiverse

free

Vase Monstrosity by barty3d

... out the assembly modeling and if i like that i will go ahead and buy. renders are in bryce 3d (green glass) and keyshot (wood).

thingiverse

free

Blood Monstrosity / Gloomhaven / Jaws of the Lion by Sevyd

...bjohnson06https://www.thingiverse.com/thing:3151039

base was made by ezowens found here:https://www.thingiverse.com/thing:2797144

Anycubic

thingiverse

free

anycubic filament holder

...anycubic filament holder

thingiverse

anycubic filament holder

thingiverse

free

Cableholder Anycubic Mega

...cableholder anycubic mega

thingiverse

cableholder anycubic mega

thingiverse

free

AnyCubic Toolholder by WildManPrinting

...anycubic toolholder by wildmanprinting

thingiverse

anycubic i3 mega toolholder that clips on the side of the spool a-frame.

thingiverse

free

AnyCubic Funnel by phana007

...anycubic funnel by phana007

thingiverse

funnel for anycubic resin and also a reducer for a normal soda bottle.

thingiverse

free

Anycubic Kossel PID calibration

...ir mount:

kossel raspberry camera ir mount

extruder pid calibration.

simple extruder temperature calibration of your 3d printer.

thingiverse

free

anycubic mega i3

...anycubic mega i3

thingiverse

anycubic i3 mega/mega s led 30mm 10-14v 6500k

thingiverse

free

Handle for anycubic by cruiser7

...handle for anycubic by cruiser7

thingiverse

its easier to handle the cover of the anycubic mono x and wash&care

thingiverse

free

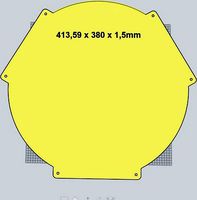

anycubic predator Printbed by Lihyon

...anycubic predator printbed by lihyon

thingiverse

anycubic predator printbed

thingiverse

free

Anycubic Predator Triggers by marcelcountry

...anycubic predator triggers by marcelcountry

thingiverse

anycubic predator triggers

thingiverse

free

support anycubic cable by sarpdental

...support anycubic cable by sarpdental

thingiverse

support anycubic cable

Mega

3ddd

$1

BoConcept / Mega

...boconcept / mega

3ddd

boconcept

boconcept mega

3ddd

free

Angelo - Mega shoin

... mega shoin , shoin

angelo - mega shoin - 3dmax 2008

3ddd

$1

Комод MEGA

...вана по фото с учетом реальных размеров.

стек не сколапсен, есть возможность регулировки уровня сглаживания.

текстуры в архиве.

3ddd

$1

Hulsta / Mega-design

...hulsta / mega-design

3ddd

hulsta

hulsta mega-design

design_connected

$18

Tolomeo Mega

...

photo-realistic 3d models of the tolomeo mega floor lamps from artemide for 3d architectural and interior design presentations.

turbosquid

$119

Mega Soldier

... free 3d model mega soldier for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1148568)

turbosquid

$100

Mega Yacht

... free 3d model mega yacht for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1368903)

3ddd

$1

Massproductions Mega

... massproductions , mega

ширина: 180 см

глубина: 90 см

высота: 79 см

3d_export

$4

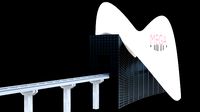

mega metro station

...mega metro station

3dexport

mega metro station. ready to game. thanks all downloaders!!

3ddd

$1

BAS Mega

...bas mega

3ddd

bas , ванна

ванна

I3

3d_export

$10

suv i3

...suv i3

3dexport

suv i3 2013 series

3d_ocean

$89

BMW i3 2012

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 20143d model

...

cgstudio

.3ds .c4d .fbx .lwo .max .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20123d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2012 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

BMW i3 20143d model

...tudio

.3ds .c4d .fbx .lwo .max .mb .obj - bmw i3 2014 3d model, royalty free license available, instant download after purchase.

humster3d

$75

3D model of BMW i3 2014

...

buy a detailed 3d model of bmw i3 2014 in various file formats. all our 3d models were created maximally close to the original.

humster3d

$40

3D model of Kitchen Set I3

...uy a detailed 3d model of kitchen set i3 in various file formats. all our 3d models were created maximally close to the original.

3d_ocean

$30

Kitchen set i3

...ensils oven plates shelves sink table ware

kitchen set i3 include 3d models: cooker, oven, sink, cupboards, table, chair, plates.

3d_ocean

$89

BMW i3 2014

...y, in real units of measurement, qualitatively and maximally close to the original. model formats: - *.max (3ds max 2008 scanl...

cg_studio

$99

BMW i3 Concept 20113d model

...i3

.3ds .c4d .fbx .lwo .max .obj - bmw i3 concept 2011 3d model, royalty free license available, instant download after purchase.