Thingiverse

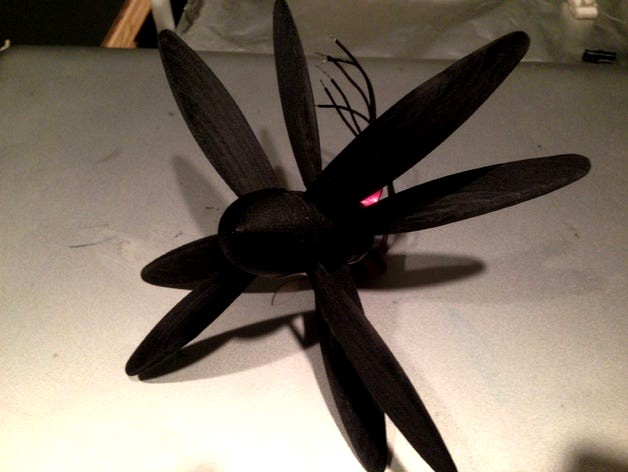

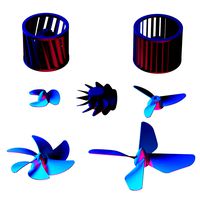

Antonov An-22 (or Tupolev Tu-95) NK-12 Model Propellers by Classicaviator

by Thingiverse

Last crawled date: 3 years ago

25-Jan-2017 update: I took down the video of the props working due to another issue I had with Youtube. Sorry about that, but the video is no longer available.

28-Jan-2014 update: The thing is finished and tested. Two more changes made to the cooling spacer and the rearward spacer. Watch video of the test run (pardon the crude setup - just using the tools available at hand) - http://youtu.be/tcZVFtfykug

24-Jan-2015 update: After printing all of the components and mounting them on the motor, I've discovered a few more issues with spacing and bolting. I've updated all of the parts and re-uploaded all of them. Also uploaded assembly progression steps.

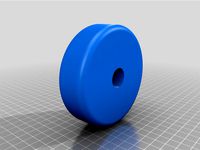

21-Jan-2015 update: Fixed blade misalignment issue. Also increased forward prop hub clearance on Prop_2. Best when printed at 0.1mm Z resolution. Updated STLs: Prop_1.stl, Prop_2.stl.

I sketched these in SolidWorks to fit my Antonov AN-22 1/40 scale RC model I am in the process of building. They fit the scale almost perfectly, and work well with the CR23S 1700KV contra-rotating electric motor (http://hobbyking.com/hobbyking/store/__17150__CR23S_Contra_Rotating_BL_System_1700kv_.html).

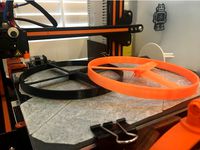

I haven't tested it yet, but have printed some of the parts, including the #1 prop (the front). The parts were sketched with FDM printing process in mind and are all printable with single extruder and no supports. However, lower resolution is recommended for the prop blades. Works especially well with ProtoPasta's new carbon PLA filament! http://www.proto-pasta.com/shop/cfpla

The blade angles are set for 45 mph maximum theoretical flight at 9600 RPM, which really means nice slow 25-30 MPH flight at mid power.

Feel free to shoot any questions my way, as well as any needed mods to the design.

Note: if you plan on using these on a real model, please consider testing these parts first in a safe environment before flying your model. I am using pretty strong materials on my end and feel they are safe, but I cannot guarantee that all filaments and materials have the same strength (they don't!). Also, sanding and bondo filling is not only recommended, it's necessary for good smooth working propellers. And, most importantly, don't forget to balance the props before they go on the motor!

28-Jan-2014 update: The thing is finished and tested. Two more changes made to the cooling spacer and the rearward spacer. Watch video of the test run (pardon the crude setup - just using the tools available at hand) - http://youtu.be/tcZVFtfykug

24-Jan-2015 update: After printing all of the components and mounting them on the motor, I've discovered a few more issues with spacing and bolting. I've updated all of the parts and re-uploaded all of them. Also uploaded assembly progression steps.

21-Jan-2015 update: Fixed blade misalignment issue. Also increased forward prop hub clearance on Prop_2. Best when printed at 0.1mm Z resolution. Updated STLs: Prop_1.stl, Prop_2.stl.

I sketched these in SolidWorks to fit my Antonov AN-22 1/40 scale RC model I am in the process of building. They fit the scale almost perfectly, and work well with the CR23S 1700KV contra-rotating electric motor (http://hobbyking.com/hobbyking/store/__17150__CR23S_Contra_Rotating_BL_System_1700kv_.html).

I haven't tested it yet, but have printed some of the parts, including the #1 prop (the front). The parts were sketched with FDM printing process in mind and are all printable with single extruder and no supports. However, lower resolution is recommended for the prop blades. Works especially well with ProtoPasta's new carbon PLA filament! http://www.proto-pasta.com/shop/cfpla

The blade angles are set for 45 mph maximum theoretical flight at 9600 RPM, which really means nice slow 25-30 MPH flight at mid power.

Feel free to shoot any questions my way, as well as any needed mods to the design.

Note: if you plan on using these on a real model, please consider testing these parts first in a safe environment before flying your model. I am using pretty strong materials on my end and feel they are safe, but I cannot guarantee that all filaments and materials have the same strength (they don't!). Also, sanding and bondo filling is not only recommended, it's necessary for good smooth working propellers. And, most importantly, don't forget to balance the props before they go on the motor!

Similar models

thingiverse

free

RC boat parts: rudder, propeller and motor mount by UngraciousOne

...op since i used counter rotating props on one side of the boat.

the parts were made in solidworks and those files are included.

thingiverse

free

2035 4 Blade Propellers For 11xx motor by Alex_E

...1st version of my propellers fo aurora 90 or similar fpv racer. suitable for 11xx brushless motor. printed with...

thingiverse

free

Dalprop folding propellers - Adapter for T-Mount motors - 2-blade conversion by eyefly

...ction molded stock upper part.

if you try them out, please share your experience in the comments. this would be much appreciated!

thingiverse

free

Folding propeller adapter - supports T-mount motors and 3-blade to 2-blade conversion by eyefly

...

currently only dalprop adapter included - gemfan will follow in a few days.

print in pla or petg.

for more details please watch:

thingiverse

free

Johnston Prop Hub by Crazydog

...ould work. i will update in the spring as to its success unless someone has a motor at home they can test it on and then comment.

grabcad

free

Motor and Propeller update

...peller on the motor and the motor , little adjustments but big improvements i have included the 2 blade and the 4 blade propeller

thingiverse

free

2" Propellers - 3 holes mounting style by Flowr

...y very also pretty solid and don't explode on crash.

3 blades pro is difficult do print, maybe try to print it on sla printer

thingiverse

free

Flywheel Propeller

...herefore hold full responsibility for your actions whilst using this. always stand behind the launcher and keep a distance."

thingiverse

free

propeller for brushless motor

...hless motor

thingiverse

this is a prop i designed hoping that it could be a replacement if needed and it did and it worked well.

thingiverse

free

Small Sebenza Insingo Representation by jor2daje

...n place (hollow spacers and actual hardware could also be used)

https://www.youtube.com/watch?v=p10fmma0heu&feature=youtu.b

Classicaviator

thingiverse

free

Wills Wing Version by Classicaviator

...great on both of my gliders. thanks for the original design idea, and hope this helps those, who have the ww style down tubes. :)

thingiverse

free

Streamlined Wheel for Wills Wing Basebar, Optimized for 3D Printing by Classicaviator

...heel can last a long time, though mine got dirty right away from muddy fields where i was landing and breaking down early spring.

thingiverse

free

Horizon Hobby Super Cub Brushless Motor Adapter by Classicaviator

...cg a bit more aft. this may not be the case for every hh super cub, but it doesn't hurt to check the cg before flying anyway.

Tupolev

turbosquid

$24

Tupolev Tu-144

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$60

tupolev tu-22 binder

...ed for other roles, notably as the tu-22r reconnaissance aircraft and as carriers for the long-range kh-22 anti-shipping missile.

3d_export

$60

tupolev tu-14 bosun

... people's republic of china. about 150 were produced and served with the mine-torpedo regiments of naval aviation until 1959.

3d_export

$60

tupolev tu-22m backfire

...i-shipping role. significant numbers remain in service with the russian air force, and as of 2014 more than 100 tu-22ms are in us

3d_export

$60

tupolev tu-95 bear

...40.a development of the bomber for maritime patrol is designated tu-142, while a passenger airliner derivative was called tu-114.

turbosquid

$30

Tupolev Tu-334 Transport Aircraft Solid Assembly Model

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Tupolev Tu-160 Supersonic Bomber Aircraft Solid Assembly Model

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$60

tupolev tu-128 fiddler

...that the bulge on the belly carried testing instruments, mistook it for a large ventral radar for a mixed interceptor/awacs role.

3d_export

$120

Tu154 aeroflot 3D Model

...model 3dexport tu 154 tu-154 airliner jetliner jet aircraft tupolev tu-154m aeroflot tu154 aeroflot 3d model tartino 24776...

3d_export

$120

Tu154M Polish Air Force 3D Model

...model 3dexport tu 154 tu-154 airliner jetliner jet aircraft tupolev poland government polish air force tu-154m tu154m polish air...

Antonov

turbosquid

$25

Antonov A-15

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$17

Antonov 225 Air Plane

...antonov 225 air plane

3dexport

antonov 225 air plane

cg_studio

$59

Antonov AN-1243d model

...embly low poly lowpoly

.3ds .max .obj - antonov an-124 3d model, royalty free license available, instant download after purchase.

turbosquid

$99

Antonov AN124 Rossija

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$99

Antonov AN124 Polet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$99

Antonov AN124 Maximus

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$99

Antonov AN124 Libya

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$99

Antonov AN124 Aeroflot

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$98

antonove a-26 aircraft

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

antonove a-15 aircraft

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Nk

design_connected

$29

NK Sofa

...nk sofa

designconnected

one kings lane nk sofa computer generated 3d model.

turbosquid

$15

Bahtroom Set NK

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Samsung NK Chimney Hood

...del samsung nk chimney hood for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1591831)

3ddd

$1

NK LOUNGE

...nk lounge

3ddd

noken

http://www.noken.com/catalogo/serie.php?idi=ru&pro;=3&ser;=lounge&mer;=int

3ddd

$1

NK DINASTY

...nk dinasty

3ddd

noken

http://www.noken.com/catalogo/serie.php?idi=ru&pro;=3&ser;=dinasty&mer;=int

3d_export

$6

C168 NK Creative 3D Model

...ing silver engagement wedding stl cad printable 3d jewelry design ring engagement

c168 nk creative 3d model 3dm168 73380 3dexport

turbosquid

$12

Noken NK Concept Wall-Hung WC

...ken nk concept wall-hung wc for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1508578)

3ddd

$1

Newton

...newton 3ddd nk , капитоне...

3ddd

$1

Люстра Italamp 2848+4 White NK White shades

...л абажура: ткань

абажур: белого цвета

лампы: e14 x 12 max. 28w

напряжение: 230v

высота: 86 см

диаметр: 86 см

количество ярусов: 2

3d_export

$8

samsung nk chimney hood

...d in it.<br>support :<br>if you have any questions, please feel free to contact us.<br>thank you for purchasing

95

design_connected

$13

Bell 95

...bell 95

designconnected

gervasoni bell 95 computer generated 3d model. designed by navone, paola.

turbosquid

$15

Curtain 95

...ty free 3d model curtain 95 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1462535)

turbosquid

$10

Table 95

...alty free 3d model table 95 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1503928)

turbosquid

$6

Lamp 95

...yalty free 3d model lamp 95 for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1500823)

turbosquid

$6

Bedcloth 95

...y free 3d model bedcloth 95 for download as max, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1531172)

turbosquid

$40

Ring 95

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$23

Building 95

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$9

Office 95

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Book 95

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Флоренция 95

...флоренция 95

3ddd

акватон

зеркало, пенал, тумба.

Propellers

design_connected

$11

Propeller

...propeller

designconnected

serien propeller pendant lights computer generated 3d model. designed by yaacov kaufman.

turbosquid

$15

propeller

...d

royalty free 3d model propeller for download as ma and max on turbosquid: 3d models for games, architecture, videos. (1401805)

turbosquid

$7

propeller

...

royalty free 3d model propeller for download as fbx and obj on turbosquid: 3d models for games, architecture, videos. (1557413)

turbosquid

free

Propeller

...id

free 3d model propeller for download as skp, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1619462)

3d_export

$10

helicopter propeller

...helicopter propeller

3dexport

helicopter propeller

3d_export

free

propeller

...propeller

3dexport

turbosquid

$6

propeller

...y free 3d model propeller for download as ige, stl, and sldpr on turbosquid: 3d models for games, architecture, videos. (1313738)

3d_export

free

aircraft propeller

...aircraft propeller

3dexport

a low poly aircraft propeller

turbosquid

$15

Propeller

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Propeller

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

22

3d_export

$25

rocks 22

...rocks 22

3dexport

rocks 3d model 22

turbosquid

$10

Luminaire - Lustre 22 22 Soleil

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$18

22 Bench

...22 bench

designconnected

etel interiores 22 bench benches computer generated 3d model. designed by etel carmona.

design_connected

$16

22 Chair

...22 chair

designconnected

etel interiores 22 chair chairs computer generated 3d model. designed by etel carmona.

3d_export

$6

tap-22

...tap-22

3dexport

3ddd

$1

Радиатор 22 типа

...радиатор 22 типа

3ddd

радиатор

радиатор 22 типа

3ddd

free

22 tube amplifier

...22 tube amplifier

3ddd

усилитель

22 tube amplifier

turbosquid

$35

Bracelet 22

...osquid

royalty free 3d model bracelet 22 for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1548228)

turbosquid

$20

jamb 22

...turbosquid

royalty free 3d model jamb 22 for download as max on turbosquid: 3d models for games, architecture, videos. (1403875)

turbosquid

$18

Earrings 22

...osquid

royalty free 3d model earrings 22 for download as 3dm on turbosquid: 3d models for games, architecture, videos. (1548880)

12

3ddd

free

декор№12

...декор№12

3ddd

декор№12

turbosquid

$25

12

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

bed 01 12/12/2019

...rbosquid

free 3d model bed_01_12/12/2019 for download as max on turbosquid: 3d models for games, architecture, videos. (1482189)

3d_export

$5

12

...12

3dexport

карабин сайга с рожком и патроном

turbosquid

$24

Chandelier MD 89330-12+12 Osgona

... chandelier md 89330-12+12 osgona for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1222937)

design_connected

$29

Nuvola 12

...nuvola 12

designconnected

gervasoni nuvola 12 computer generated 3d model. designed by navone, paola.

design_connected

$25

Kilt 12

...kilt 12

designconnected

zanotta kilt 12 computer generated 3d model. designed by progetti, emaf.

design_connected

$11

Domino 12

...domino 12

designconnected

zanotta domino 12 computer generated 3d model. designed by progetti, emaf.

design_connected

$9

Croco 12

...croco 12

designconnected

gervasoni croco 12 computer generated 3d model. designed by navone, paola.

design_connected

$16

X.12

...x.12

designconnected

bernini x.12 chairs computer generated 3d model. designed by franco poli.