Thingiverse

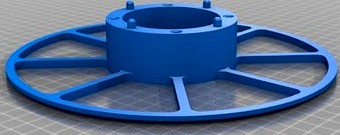

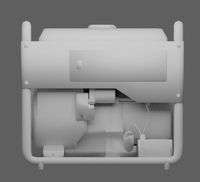

Another Generic Spool for low cost uses by DarkAlaranth

by Thingiverse

Last crawled date: 3 years, 1 month ago

Update #3

Been awhile, but I altered my usual design to use bars that follow the curve of the center. This increases surface area to make the join stronger. Made this modification after the delivery company dropped one of these spools and the pegs sheared off. As a nice bonus, less support for the extender piece. :)

If your printer is very accurate (my new ender 3 pro seems more accurate than my CR10-S5) then the pieces may not fit together tightly. Superglue can help in this regard, although I'm considering making more STLs with different clearances. Sometimes 2 different clearances will go together better than 2 of the same clearance. Or maybe add vertical ridges on the pegs to grip the receiving holes better. :)

There's also a pretty fillet now between the spokes of the spool and it's center shaft. This is optimized for the RG6 cable that i use the spools for, but i can provide one without this if desired. Seems to help stability a little bit too.

Update #2

Added a new part, the extender. It goes between the 2 sides and allows one to put more cable, filament or whatever on the spool. This allows me to have separate pieces and adjust the spool after printing to the size I need. The STL provided increases the height of the spool by just over 100% to allow twice as much on the spool. Strength didn't seem affected by the extender.

The only downside is it does need supports, which makes one end a bit rough. If I think of a better design, expect a rework of the spool. ;) I have had a suggestion of a screw thread design in the center of the spool to increase re-usability. It may be considered for the reuse factor, although I suspect it may use more material. Certainly would help in regards to filament reel use.

Any advice for reducing material use without affecting spool strength would be appreciated.

I have also included the Autodesk Fusion 360 file so it's parameters can be changed if someone wants to alter the design. I can also create new STL files of different sizes if requested. :)End of Update #2Update #1

Fixed the spoke length not being calculated for larger spools (Added a calculation to handle it)

Fixed Spoke width making spokes going off-center (Fixed some constraints in the sketch)

The 3Kg Spool file is built off V1 as it is the same from V2 still.

The 5Kg Spool file is built of the new V2 file. Definitely needs a bigger than 300mm build volume. (I have a CR10 S5)

End of Update #1

First off, this needs to be printed twice for a functional spool. Designed to not need supports.

I built this to ship cables easier in Australia Post Bags, allowing for a reduction in postage costs on our online store and realised it can be used for nearly any spool like use really, including the obvious filament rolls.

My boss thinks it looks like a firehose reel, moreso when the cable was wound on! ^_^

I'll be interested in what parameters people use in the uploaded Fusion 360 file in relation to the task they used it for. I'll probably come back with specs for the eSun refill packs if someone doesn't beat me to it... ;)

If someone has specific measurements for common-ish uses, I can create the STL and uploaded here.

The current STL file results in a nice lightweight spool that costs me approx. $1.90 in eSun PLA+ filament (1KG roll price in AUD), and weighed in at 42g per half spool, or 84g total and fits quite nicely in AUPost's 3KG bags. See print settings to see how I got it nice and light. :)

Been awhile, but I altered my usual design to use bars that follow the curve of the center. This increases surface area to make the join stronger. Made this modification after the delivery company dropped one of these spools and the pegs sheared off. As a nice bonus, less support for the extender piece. :)

If your printer is very accurate (my new ender 3 pro seems more accurate than my CR10-S5) then the pieces may not fit together tightly. Superglue can help in this regard, although I'm considering making more STLs with different clearances. Sometimes 2 different clearances will go together better than 2 of the same clearance. Or maybe add vertical ridges on the pegs to grip the receiving holes better. :)

There's also a pretty fillet now between the spokes of the spool and it's center shaft. This is optimized for the RG6 cable that i use the spools for, but i can provide one without this if desired. Seems to help stability a little bit too.

Update #2

Added a new part, the extender. It goes between the 2 sides and allows one to put more cable, filament or whatever on the spool. This allows me to have separate pieces and adjust the spool after printing to the size I need. The STL provided increases the height of the spool by just over 100% to allow twice as much on the spool. Strength didn't seem affected by the extender.

The only downside is it does need supports, which makes one end a bit rough. If I think of a better design, expect a rework of the spool. ;) I have had a suggestion of a screw thread design in the center of the spool to increase re-usability. It may be considered for the reuse factor, although I suspect it may use more material. Certainly would help in regards to filament reel use.

Any advice for reducing material use without affecting spool strength would be appreciated.

I have also included the Autodesk Fusion 360 file so it's parameters can be changed if someone wants to alter the design. I can also create new STL files of different sizes if requested. :)End of Update #2Update #1

Fixed the spoke length not being calculated for larger spools (Added a calculation to handle it)

Fixed Spoke width making spokes going off-center (Fixed some constraints in the sketch)

The 3Kg Spool file is built off V1 as it is the same from V2 still.

The 5Kg Spool file is built of the new V2 file. Definitely needs a bigger than 300mm build volume. (I have a CR10 S5)

End of Update #1

First off, this needs to be printed twice for a functional spool. Designed to not need supports.

I built this to ship cables easier in Australia Post Bags, allowing for a reduction in postage costs on our online store and realised it can be used for nearly any spool like use really, including the obvious filament rolls.

My boss thinks it looks like a firehose reel, moreso when the cable was wound on! ^_^

I'll be interested in what parameters people use in the uploaded Fusion 360 file in relation to the task they used it for. I'll probably come back with specs for the eSun refill packs if someone doesn't beat me to it... ;)

If someone has specific measurements for common-ish uses, I can create the STL and uploaded here.

The current STL file results in a nice lightweight spool that costs me approx. $1.90 in eSun PLA+ filament (1KG roll price in AUD), and weighed in at 42g per half spool, or 84g total and fits quite nicely in AUPost's 3KG bags. See print settings to see how I got it nice and light. :)

Similar models

thingiverse

free

eSUN 3Kg Spool Holder

...esun 3kg spool holder

thingiverse

esun 3kg spool holder

grabcad

free

eSun 3kg filament spool holder

...esun 3kg filament spool holder

grabcad

in addition, you need:

4x

bearing 10x26x8

m5x35 bolt

m5 nut

thingiverse

free

eSun Spool Drawers by ElmoC

...e a label and another without the label holder. if you are only using one spool, the you do not need the extension or link file.

thingiverse

free

Filament Guide by hbaulig

...pool and had no problems since.

you can use the existing screws to fit it and use a cable tie to locate the cables in the center.

thingiverse

free

eSun to Push Plastic Spool Adapter by ershsdhadgasg

...o hear about whether it fits refills from other filament companies. send me a message and i'll update a compatibility list.

grabcad

free

Voron 2 Spool Holder Large Configurable

...the spool width and the holder height. i recommend higher spool holder for heavier and large spools where the com is further out.

thingiverse

free

Keep Spool Aligned by telmovmx

...tended it to the full length of the black tube, making the piece not only a stabilizer but also centered with the filament spool.

thingiverse

free

Filament spool holder, for big (3Kg) & regular (0.75-1Kg) spool size by svetlov

...rsal filament spool mount. designed for 3kg big spool, but you can use this mount for any other size of filament spool. enjoy! :)

thingiverse

free

Master spool (refill) from eono spool by toastfr35

... inner diameter of the spool to match 'esun refilament'.

no support needed.

prints ok at 0.35mm layer with a 0.6mm nozzle

thingiverse

free

105mm Raise3D Spool Holder by BrownA

... by browna

thingiverse

length extended to 105mm to accept rigidink's 3kg filament spools or any spool with a width of 100mm.

Darkalaranth

thingiverse

free

Suburu Replacement Exterior Trim Holder Clip by DarkAlaranth

...approx 52 minutes

sliced in cura with supports enabled.

printed at 215c on hotend, 70c on bed. using a brim for adhesion to glass

thingiverse

free

TL4076 Filament Feeder Guide ***Updated*** by DarkAlaranth

...th bearing setup for a 3kg filament roll or the printer pulls itself to towards the roll stuffing up any bed leveling.. >_<

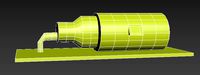

Spool

3ddd

$1

spool c53301

...spool c53301

3ddd

spool

spool c53301 650х350х145

turbosquid

$3

Cable Spool

...royalty free 3d model cable spool for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1457009)

turbosquid

free

Pallets and Spool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Spool of String

...ol of string pink for download as c4d, 3ds, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1647892)

3ddd

$1

Подвесные светильники Spool

...ye/podvesnoy_svetilnik_spool_d320/ http://www.cosmorelax.ru/catalog/podvesnyye/podvesnoy_svetilnik_spool_d420/

3ddd

free

Spool 001 sofa

...spool 001 sofa

3ddd

roda

roda

collection spool

design rodolfo dordoni

dimensions:

lenght 90 cm

depth 94 cm

height 79 cm

turbosquid

$15

Roda Spool Sofa

...ee 3d model roda spool sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1502650)

turbosquid

$95

wire spools 3ds

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

spool of TV wire

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Simple and Fast Spool Holder

...ree 3d model simple and fast spool holder for download as stl on turbosquid: 3d models for games, architecture, videos. (1548546)

Cost

3ddd

$1

Кресло Costes

...кресло costes

3ddd

costes

кресло costes

design_connected

$11

Costes armchair

...costes armchair

designconnected

eric kuster costes armchair computer generated 3d model.

design_connected

$16

King Costes

...king costes

designconnected

driade king costes chairs computer generated 3d model. designed by philippe starck.

3ddd

$1

driade - KING COSTES

...stes

каркас выполнен из алюминия, сидение и спинка из ореха или дуба. обивка:кожа черного или бежевого цвета. размер: 50,5х56х47h

turbosquid

$13

Ethimo Costes Sofa

...3d model ethimo costes sofa for download as max, max, and max on turbosquid: 3d models for games, architecture, videos. (1580650)

turbosquid

$28

KING COSTES by DRIADE

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

Low Back Costs Chair

...d + corona

cinema 4d + vrayforc4d

obj

textures included

tags: max2014, c4d, cosmorelax, chair, lounge, cosmo, corona, vrayforc4d

turbosquid

$10

Sumo Warrior ( low cost game ready model )

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$8

Wooden Barrel ( low cost game ready model )

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Low cost High Def Iphone 4G Black and White1

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Another

turbosquid

$15

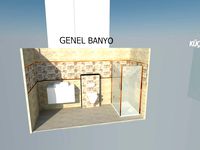

ANOTHER BATHROOM

...quid

royalty free 3d model another bathroom for download as on turbosquid: 3d models for games, architecture, videos. (1171460)

turbosquid

$24

Another World

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$39

Another Red Curb

...ee 3d model another red curb for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1182913)

turbosquid

$9

Another Deberenn Sofa

...model another deberenn sofa for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1497850)

turbosquid

$2

Another picnic table

... model another picnic table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1426381)

turbosquid

$15

door to another world

...oor to another world for download as 3ds, obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1334842)

3d_export

free

another hacksaw

...another hacksaw

3dexport

. . . 3d model of a hacksaw. 3d model files: - 3ds max 2017 (scanline) - obj (low poly) . . .

turbosquid

$12

Another Country Side Table

... another country side table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1496053)

turbosquid

$29

Furniture - "Another country" modern sofa

...another country" modern sofa for download as obj and c4d on turbosquid: 3d models for games, architecture, videos. (1186189)

3d_ocean

$29

Another Tron Light Cycle with the Rider and Trail

...ther tron light cycle with the rider and the light trail. high quality 3d model,all the materials and lights are included. the...

Generic

3d_export

$17

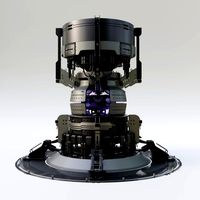

Generator

...generator

3dexport

generator

archibase_planet

free

Generator

...base planet

generator electric generator

generator electric n300715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

design_connected

$20

Generation

...generation

designconnected

knoll generation computer generated 3d model. designed by formway design.

3d_export

$8

generator

...generator

3dexport

generator - obj, 3ds, fbx.

3d_export

$7

generator

...generator

3dexport

generator extures 4k resolution, basecolor -normal -metallic -ao-roughness-height tris:3084

turbosquid

free

generator

...rator

turbosquid

free 3d model generator for download as max on turbosquid: 3d models for games, architecture, videos. (1492909)

3ddd

$1

general

...general

3ddd

генерал

turbosquid

$99

generator

...urbosquid

royalty free 3d model generator for download as ma on turbosquid: 3d models for games, architecture, videos. (1514125)

turbosquid

$20

Generator

...rbosquid

royalty free 3d model generator for download as max on turbosquid: 3d models for games, architecture, videos. (1244841)

turbosquid

$2

Generator

...rbosquid

royalty free 3d model generator for download as fbx on turbosquid: 3d models for games, architecture, videos. (1245541)

Uses

3ddd

$1

US flag

...us flag

3ddd

флаг

us flag

3d_export

free

Among us

...among us

3dexport

among us red

3d_export

free

Among Us

...among us

3dexport

this 3d-model of a character from the game "among us". it can be used as a toy or decoration.

3d_export

$6

among us

...among us

3dexport

doll from among us in red

3d_export

$5

amoung us

...amoung us

3dexport

amoung us character. was created by cinema 4d 19

3d_export

$5

Humvee us

...humvee us

3dexport

humvee us 3d model good quality for animation

3d_export

$15

among us

...among us

3dexport

turbosmooth modifier can be used to increase mesh resolution if necessary

3d_export

$25

mailbox us

...mailbox us

3dexport

low poly model mailbox us. modeling in the blender, texturing in substance painter

design_connected

$13

Use Me

...use me

designconnected

sitland use me computer generated 3d model. designed by paolo scagnellato.

3d_export

$5

Among Us

...rt

the among us model comes in a variety of colors that can be customized by anyone, and even works with little in the animation