Thingiverse

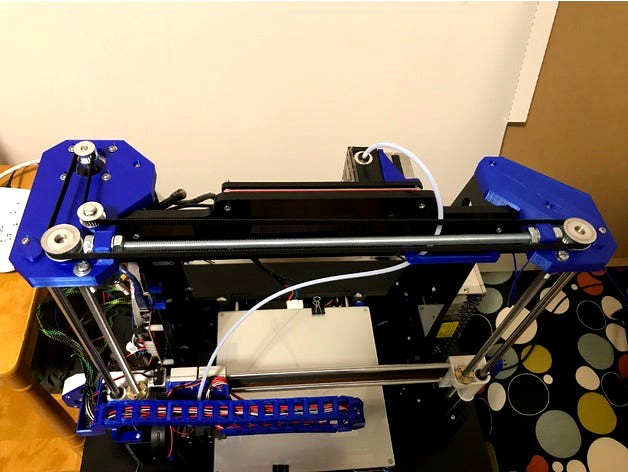

Anet A8 single motor Z axis drive by osadchy

by Thingiverse

Last crawled date: 3 years ago

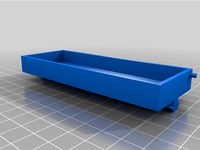

This is a way to sync the Z-axis drive using a single motor.

Printed parts:

plateL.stl - top left plate, the motor and idler are mounted here

plateR.stl - top right plate, essentially a mirror image of the left plate, but without the motor and pulley.

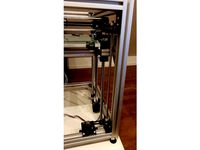

rod_plug.stl (print 2) - replaces the original guiding rod plugs on top plates

rod_holder.stl (print 2) - holds the guiding rods from below, since the motors aren't there anymore

tube_guard.stl (optional) - keeps my bowden tube from interfering with the timing belt

If you prefer the motor on the right, you can print mirror images of the plateL.stl and plateR.stl.

Hardware needed:

use the original 4 M3 screws and nuts to mount the top plates

976mm 488 teeth GT2 (6mm) closed belt (https://www.aliexpress.com/item/Hot-sales-GT2-timing-belt-976-2GT-6-length-976mm-width-6mm-teeth-488-for-3D/32299312364.html)

GT2 18 teeth pulley 5mm bore - mounted on the motor (https://www.aliexpress.com/item/3d-printer-2GT-GT2-Timing-Pulley-18-teeth-Alumium-Bore-5mm-for-GT2-Belt-Width-6mm/32835852375.html)

2x flange bearings 8mm bore (https://www.aliexpress.com/item/8mm-Bearing-Zinc-Alloy-Miniature-Bearing-Pedestal-KFL08-Flange-Pillow-Block-Bearing-diy-cnc-parts/32773248332.html)

2x GT2 36teeth timing pulleys with 8mm bore (https://www.aliexpress.com/item/3d-printer-pulley-aluminum-timing-pulley-2GT-36teeth-bore-5mm-6mm-6-35mm-8mm-10mm-pulley/32658350983.html)

1x idler pulley for GT2, 5mm bore - (https://www.aliexpress.com/item/Timing-Gear-Pulley-Without-tooth-Idle-Pulley-synchronous-Round-5mm-For-GT2-Belt-Width-6MM-Power/32761426168.html)

M8 rod, length 349mm - needed to stiffen the frame, because the frame is too flimsy to withstand the timing belt tension

4x M8 nuts and washers to fix the M8 rod

4x M5 25mm screws and nuts and washers - to fix the flange bearings

1x M5 40mm screw and 2x M5 nuts and a washer - to mount the pulley idler

2x M3 20mm screws and nuts for the top rod plugs

4x M3 15mm screws and nuts to mount the bottom rod holders

4x M3 12mm screws and washers for motor mounting

The mounting holes for the flange bearings are a bit oversized so you can keep the leadscrews and the guiding rods parallel. The way I did it:

Mount the flange bearing without tightening the mounting screws

fix the leadscrews in the bearings

bring the X-axis assembly (the one that rides on the leadscrews and rods) all the way up (maximal expected Z height)

ensure that the leadscrews are parallel to the guiding rods (I eyeballed it, by keeping the bottom of the leadscrews above the Z motor axes, which were yet unmounted at this stage).

tighten the flange bearing mounting screws

Don't forget to change the steps/mm parameter for the z axis (from the original 400 to 800)

Hope I included everything here. If you find anything missing, please comment and I'll answer/update.

Printed parts:

plateL.stl - top left plate, the motor and idler are mounted here

plateR.stl - top right plate, essentially a mirror image of the left plate, but without the motor and pulley.

rod_plug.stl (print 2) - replaces the original guiding rod plugs on top plates

rod_holder.stl (print 2) - holds the guiding rods from below, since the motors aren't there anymore

tube_guard.stl (optional) - keeps my bowden tube from interfering with the timing belt

If you prefer the motor on the right, you can print mirror images of the plateL.stl and plateR.stl.

Hardware needed:

use the original 4 M3 screws and nuts to mount the top plates

976mm 488 teeth GT2 (6mm) closed belt (https://www.aliexpress.com/item/Hot-sales-GT2-timing-belt-976-2GT-6-length-976mm-width-6mm-teeth-488-for-3D/32299312364.html)

GT2 18 teeth pulley 5mm bore - mounted on the motor (https://www.aliexpress.com/item/3d-printer-2GT-GT2-Timing-Pulley-18-teeth-Alumium-Bore-5mm-for-GT2-Belt-Width-6mm/32835852375.html)

2x flange bearings 8mm bore (https://www.aliexpress.com/item/8mm-Bearing-Zinc-Alloy-Miniature-Bearing-Pedestal-KFL08-Flange-Pillow-Block-Bearing-diy-cnc-parts/32773248332.html)

2x GT2 36teeth timing pulleys with 8mm bore (https://www.aliexpress.com/item/3d-printer-pulley-aluminum-timing-pulley-2GT-36teeth-bore-5mm-6mm-6-35mm-8mm-10mm-pulley/32658350983.html)

1x idler pulley for GT2, 5mm bore - (https://www.aliexpress.com/item/Timing-Gear-Pulley-Without-tooth-Idle-Pulley-synchronous-Round-5mm-For-GT2-Belt-Width-6MM-Power/32761426168.html)

M8 rod, length 349mm - needed to stiffen the frame, because the frame is too flimsy to withstand the timing belt tension

4x M8 nuts and washers to fix the M8 rod

4x M5 25mm screws and nuts and washers - to fix the flange bearings

1x M5 40mm screw and 2x M5 nuts and a washer - to mount the pulley idler

2x M3 20mm screws and nuts for the top rod plugs

4x M3 15mm screws and nuts to mount the bottom rod holders

4x M3 12mm screws and washers for motor mounting

The mounting holes for the flange bearings are a bit oversized so you can keep the leadscrews and the guiding rods parallel. The way I did it:

Mount the flange bearing without tightening the mounting screws

fix the leadscrews in the bearings

bring the X-axis assembly (the one that rides on the leadscrews and rods) all the way up (maximal expected Z height)

ensure that the leadscrews are parallel to the guiding rods (I eyeballed it, by keeping the bottom of the leadscrews above the Z motor axes, which were yet unmounted at this stage).

tighten the flange bearing mounting screws

Don't forget to change the steps/mm parameter for the z axis (from the original 400 to 800)

Hope I included everything here. If you find anything missing, please comment and I'll answer/update.

Similar models

thingiverse

free

Tevo Tarantula Single Motor Dual Z Axis by olala2

...ng 8mm - not sure about translation to english and haven´t got link because i am using my 2nd 20teeth gt2 timing pulley bore 8mm)

thingiverse

free

K40 (with wheels) Adjustable Bed by psaik

...ps://www.aliexpress.com/item/free-shipping-1pcs-lot-gt2-1140-closed-loop-rubber-2gt-timing-belt-1140-gt2-6-teeth/32791435275.html

thingiverse

free

Openbeam Printer by xsmarty

...e

also i am using a 300mmx300mm silicon adhesive heatpad

i hope you enjoy my designhttps://www.youtube.com/watch?v=auoyjmhpzpw

grabcad

free

2GT-20T BF Pulleys

...elt widths; 5mm, 6mm, and 8mm bore sizes. m4 set screws in the model. the render is of a pulley for a 10mm belt with an 8mm bore.

thingiverse

free

Camera Pan/Tilt Head by suromark

...gs

30mm x 5mm ø steel shaft

55mm x 8mm ø steel shaft

keystone network wiring module

m8 screw 60-100mm

m4 screws

m3 screws

washers

thingiverse

free

Hypercube Evolution - XY Bottom Mount by VirDim

...4x gt2 20t 8*2mm bore timing belt idler pulley

4x 608zz bearings

2x z-motor mount from: https://www.thingiverse.com/thing:2254103

grabcad

free

2GT-40T Pulleys

...lt widths; 6mm, 8mm, and 10mm bore sizes. m4 set screws in the model. the render is of a pulley for a 10mm belt with an 8mm bore.

grabcad

free

2GT-60T Pulleys

...ths; 6mm, 8mm, 10mm, and 12mm bore sizes. m4 set screws in the model. the render is of a pulley for a 10mm belt with an 8mm bore.

grabcad

free

2GT-40T BF Pulleys

...lt widths; 6mm, 8mm, and 10mm bore sizes. m4 set screws in the model. the render is of a pulley for a 10mm belt with an 8mm bore.

thingiverse

free

GT2 32T pulley 625 Bearing by junkhack

...gt2 32t pulley 625 bearing by junkhack

thingiverse

gt2 32 teeth bore 16mm (625zz bearing bore 5mm)

6mm belt

Osadchy

thingiverse

free

Helping hands mount by osadchy

...ping hands mount by osadchy

thingiverse

this is a helping hand mount. attached with a single screw (in my case to a wooden base)

thingiverse

free

Lower dual mosfet mount for Anet A8 by osadchy

...lower dual mosfet mount for anet a8 by osadchy

thingiverse

another dual mosfet mount - below the main board.

thingiverse

free

QX70 prop cutting jig by osadchy

...s for eachine qx70

if the prop doesn't fit into the center hole, the hole should be widened with a 3.5mm drill bit (by hand).

thingiverse

free

Parametric spool holder with hyperbolic cutouts by osadchy

...wkwardly implemented in openscad).

number of cutouts, and few other parameters are customizable (as described in the scad file).

thingiverse

free

TBS Unify Pro 5G8 V2VTX and Antenna mount for Alien 5" frame by osadchy

...the tbs unify pro 5g8 v2 video transmitter and antenna.

total weight 2.4g

not sure yet how the pla mount will handle the vtx heat

thingiverse

free

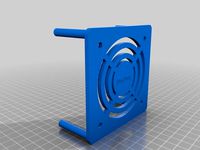

Anet A8 120mm fan holder for power supply by osadchy

...mm vertical hole spacing, with each row of holes shifted half horizontal spacing (i think this is standard anet a8 power supply)

thingiverse

free

Self locking Y belt holder for Anet A8 by osadchy

...have a different spring). the file includes an over-complicated exact gt2 belt model, as an scad programming exercise for myself.

A8

turbosquid

$47

Car A8

...

turbosquid

royalty free 3d model car a8 for download as max on turbosquid: 3d models for games, architecture, videos. (1196060)

turbosquid

$50

Audi A8

...yalty free 3d model audi a8 for download as 3dm, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1580187)

turbosquid

$15

Audi A8

...lty free 3d model audi a8 for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1387519)

turbosquid

$500

Audi A8

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Audi A8 3D Model

...audi a8 3d model

3dexport

audi a8 cars car

audi a8 3d model ma 20351 3dexport

3d_export

$5

Audi A8 3D Model

...audi a8 3d model

3dexport

3d model of audi a8

audi a8 3d model badyaka 12136 3dexport

3d_ocean

$89

Audi A8 2010

...usiness car car class class f f german german luxury luxury s s s8 s8 sedan sedan vehicle vehicle

new audi a8 2010 detaled model.

turbosquid

$39

A8 2018

...a8 2018 for download as 3ds, obj, wrl, c4d, fbx, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1345349)

turbosquid

free

audi a8 l

...rbosquid

royalty free 3d model audi a8 l for download as obj on turbosquid: 3d models for games, architecture, videos. (1663016)

3d_ocean

$45

Audi A8 restyled

...our door vehicle was created in blender3d 2.62.realistic renderings were created with yafaray 0.1.2 realistic plugin.rendering...

Anet

thingiverse

free

Anet by derbodesign

...anet by derbodesign

thingiverse

logo anet

thingiverse

free

Anet e10 , Anet v1.0 by jonathan_943D

...anet e10 , anet v1.0 by jonathan_943d

thingiverse

soporte de ventilador de 80mm, para controladora anet v1.0

thingiverse

free

Anet A8 Anet AM8 Y belt holder

...anet a8 anet am8 y belt holder

thingiverse

anet a8 anet am8 y belt holder

thingiverse

free

Anet A8 Probe Bracket for anet sensor by chelrix

...anet a8 probe bracket for anet sensor by chelrix

thingiverse

anet a8 probe bracket for anet official sensor and marlin firmware

thingiverse

free

Anet logo by JUST3D_PRNTNG

...anet logo by just3d_prntng

thingiverse

anet logo

thingiverse

free

Fan nozzle for Anet A8 with original Anet levelsensor by peteruhlmann

...et levelsensor by peteruhlmann

thingiverse

here is an improved fan nozzle for the anet a8 with original level sensor from anet.

thingiverse

free

Anet Et4 Box

...anet et4 box

thingiverse

tool box for anet et4

thingiverse

free

Anet Logo by Superflex_Plastic_Fantastic

...anet logo by superflex_plastic_fantastic

thingiverse

anet logo to incorporate into designs.

thingiverse

free

Box for Anet ET4

...box for anet et4

thingiverse

this is a simple box for tool of anet et4

thingiverse

free

Anet V1.0 Board Kühlung (80mm Lüfter) / Anet A8 by MadCre8

...anet v1.0 board kühlung (80mm lüfter) / anet a8 by madcre8

thingiverse

anet v1.0 board kühlung (80mm lüfter) / anet a8

Drive

turbosquid

$90

Drive

...turbosquid

royalty free 3d model drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1654393)

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$60

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1254314)

turbosquid

$50

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1263524)

turbosquid

$45

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1287060)

turbosquid

$40

Star Drive

...squid

royalty free 3d model star drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1261902)

Axis

3ddd

$1

Мария Axis

...

3ddd

кухня , классическая , axis

модель кухни.

3d_export

$22

Axis robot 6-axis robotic arm

...ing parts drawings, standard parts purchased parts list, can be produced directly according to the drawings, welcome to download!

3ddd

free

Versatile Axis

...ddd

nexus , плитка

http://bvtileandstone.com/ceramic-porcelain/versatile-axis/

3d_export

$19

robot 2 axis

...robot 2 axis

3dexport

robot 2 axis

turbosquid

$40

Axis R5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$40

Axis S5F

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Axis Athlon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Linear Axis

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

drawing axis

...drawing axis

3dexport

simple rendering of the scene file

3ddd

$1

versatile axis ARC

...versatile axis arc

3ddd

versatile , плитка

versatile axis arc red dot design award

Z

3d_export

$5

nissan z

...nissan z

3dexport

nissan z

3ddd

$1

Vase Z

...vase z

3ddd

vase z

3ddd

$1

полотенцесушить Z

...полотенцесушить z

3ddd

полотенцесушитель

полотенцесушить z

design_connected

free

Z-Chair

...z-chair

designconnected

free 3d model of z-chair designed by karman, aleksei.

design_connected

$11

Z Lamp

...z lamp

designconnected

phillips z lamp computer generated 3d model. designed by kalff, louis.

3d_export

$5

Dragon balls z

...dragon balls z

3dexport

dragon ball z

turbosquid

$20

Fighter Z

...

turbosquid

royalty free 3d model fighter z for download as on turbosquid: 3d models for games, architecture, videos. (1292563)

turbosquid

$9

Pen Z

...pen z

turbosquid

free 3d model pen z for download as obj on turbosquid: 3d models for games, architecture, videos. (1686775)

turbosquid

free

z chair

...z chair

turbosquid

free 3d model z chair for download as max on turbosquid: 3d models for games, architecture, videos. (1410230)

turbosquid

$5

Letter Z

...urbosquid

royalty free 3d model letter z for download as max on turbosquid: 3d models for games, architecture, videos. (1408540)

Motor

archibase_planet

free

Motor

...base planet

motor motor engine engine electric motor

motor wagner n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n151112 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n150615 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$15

Motor

...otor

turbosquid

royalty free 3d model motor for download as on turbosquid: 3d models for games, architecture, videos. (1639404)

3d_ocean

$5

Electric motor

...electric motor

3docean

car electric engine industry motor phase train vehicle

an electric motor enjoy!

3d_ocean

$18

Electric Motor

...electric motor

3docean

electric motor engine machine mover parts

3d model electric motor for hoist crane

turbosquid

$29

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

electric motor

...electric motor

3dexport

electric motor use for industrial purposes

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.

Single

3d_export

$5

single sofa single chair

...single sofa single chair

3dexport

single sofa single chair 3d model

3d_export

$5

single sofa single chair

...single sofa single chair

3dexport

single sofa single chair 3d model

3d_export

$5

single fastener

...single fastener

3dexport

single fastener

3ddd

$1

Single FLOU

... sofa , трансформер

диван-трансформер single от итальянского производителя flou

3ddd

$1

bed single

...bed single

3ddd

постельное белье

bed single 190cm*90cm

3ddd

$1

Single Flou

...single flou

3ddd

качественная моделька дивана-трансформера single flou.

3d_ocean

$9

Single sofa

...le sofa

3docean

modern sofa single sofa sofa white sofa.comfortable sofa

single sofa,sofa,modern sofa,white sofa.comfortable sofa

3d_export

free

Single Knife

...single knife

3dexport

a single knife, presumably it was used as one of the throwing knives.

3d_export

free

couch - single

...couch - single

3dexport

low poly single couch with .psd file for personal customization

3d_ocean

$5

Single Sofa

...single sofa

3docean

single sofa made by fabric , wood frame & ss leg