Thingiverse

Anet A8 3DTouch/BLTouch Auto Leveling Sensor Bracket by JMadison

by Thingiverse

Last crawled date: 3 years ago

Update 30-APR-2017: I added the config file that I’ve been giving to people who ask for my config file. The configuration enclosed is the original 5 button configuration file of SkynetV2.3.1 modified to support 3DTouch/BLTouch. Note that this is for SkynetV2.3.1.

--- End of update ---

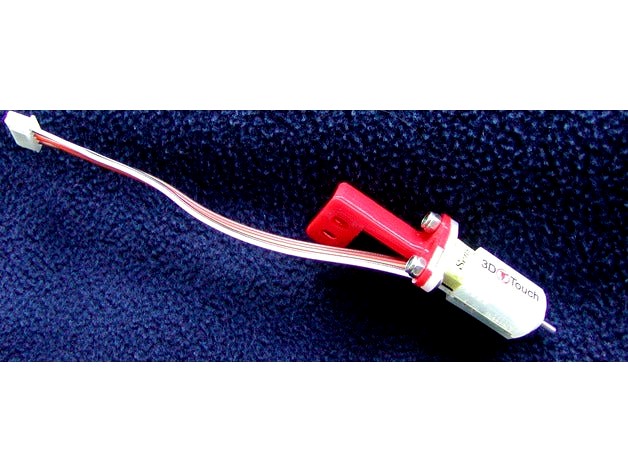

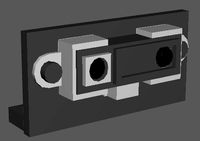

The 3DTouch/BLTouch sensor is a servo based sensor. Its main advantage is that it allows you to easily move between printing on glass or directly on the bed, without having to adjust auto leveling parameters. This sensor requires an additional pin that isn’t easily available on the Anet V1/Sanguinololu control board. To use this sensor on an Anet A8, you either have to move to a different board, modify the LCD cabling (see http://www.thingiverse.com/thing:2091529), or free up a pin on the Anet board by converting the display to I2C. See my design for freeing up a pin: http://www.thingiverse.com/thing:2098646 .

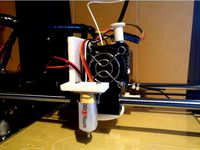

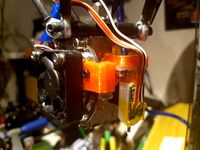

There are several 3DTouch brackets available on Thingiverse. Most won’t fit the Anet A8. The one that I found that would probably fit (http://www.thingiverse.com/thing:2084025 ) moves the sensor so that it’s almost in line with the fan, and it’s right next to the extruder cooling fins. This limits the bed area available to the probe in the Y direction. My design limits the X direction, but less than the limitation of the design that limits the Y direction.

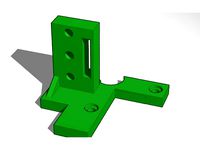

My design will only work on Anet A8s that have the same hole pattern on the extruder carriage as mine. This is a very tight fit. It should not touch anything and is greater than the manufacturer's minimum suggested distance of 15mm from the hot end/nozzle.

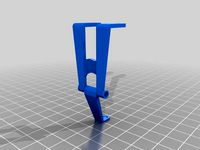

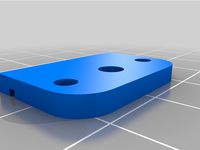

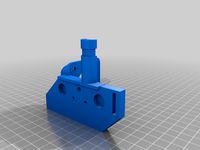

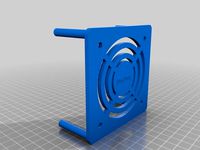

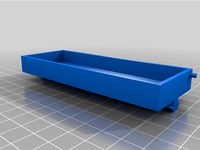

Prints: SensorBracket.stl, AlignmentSpacer.stl

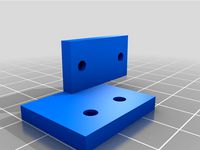

I printed both at 100% fill, 0.1mm, support “Touching Bed". I’m not a print settings expert, but I figured the bracket needs to be as rigid as possible. The alignment spacer is the distance from the base of the sensor to the bed when the nozzle is a paper thickness above the bed. The spacer is only as precise as your printer. Mine was dead on (today). It should measure 8.3mm on a good day.

Mount the sensor on the bracket before attaching the bracket to the extruder carriage.

Use Repetier-Host, Cura, etc., to place the nozzle the thickness of a sheet of paper off the bed. Use the alignment widget to set the height of the sensor above the bed.

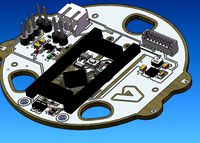

Some of the Marlin/SkynetV2.3.1 Configuration.h settings: (the others you can get from the manufacturer’s documentation)

I determined these two offsets using the grid file "Coords mm.pdf"

define X_PROBE_OFFSET_FROM_EXTRUDER 59 // X offset: -left +right [of the nozzle]

define Y_PROBE_OFFSET_FROM_EXTRUDER 14 // Y offset: -front +behind [the nozzle]

The Z_PROBE_OFFSET_FROM_EXTRUDER setting should be set based on your actual results you measure during setup.

define LEFT_PROBE_BED_POSITION 15

define RIGHT_PROBE_BED_POSITION 195

define BACK_PROBE_BED_POSITION 205

define FRONT_PROBE_BED_POSITION 25

If you use a non-standard servo pin you’ll need to define SERVO0_PIN. In my case it’s 27.

define SERVO0_PIN 27

DO NOT attempt to do an Auto Home after your very first upload. Send one of the test gcodes to make sure you're connected.

M280 P0 S10 ; pushes the pin down

M280 P0 S90 ; pulls the pin up

M280 P0 S120 ; Self test – keeps going until you do pin up/down or release alarm

M280 P0 S160 ; Release alarm

Hardware: (2) M3 x 8, (2) M3 x 12, (4) M3 nuts

--- End of update ---

The 3DTouch/BLTouch sensor is a servo based sensor. Its main advantage is that it allows you to easily move between printing on glass or directly on the bed, without having to adjust auto leveling parameters. This sensor requires an additional pin that isn’t easily available on the Anet V1/Sanguinololu control board. To use this sensor on an Anet A8, you either have to move to a different board, modify the LCD cabling (see http://www.thingiverse.com/thing:2091529), or free up a pin on the Anet board by converting the display to I2C. See my design for freeing up a pin: http://www.thingiverse.com/thing:2098646 .

There are several 3DTouch brackets available on Thingiverse. Most won’t fit the Anet A8. The one that I found that would probably fit (http://www.thingiverse.com/thing:2084025 ) moves the sensor so that it’s almost in line with the fan, and it’s right next to the extruder cooling fins. This limits the bed area available to the probe in the Y direction. My design limits the X direction, but less than the limitation of the design that limits the Y direction.

My design will only work on Anet A8s that have the same hole pattern on the extruder carriage as mine. This is a very tight fit. It should not touch anything and is greater than the manufacturer's minimum suggested distance of 15mm from the hot end/nozzle.

Prints: SensorBracket.stl, AlignmentSpacer.stl

I printed both at 100% fill, 0.1mm, support “Touching Bed". I’m not a print settings expert, but I figured the bracket needs to be as rigid as possible. The alignment spacer is the distance from the base of the sensor to the bed when the nozzle is a paper thickness above the bed. The spacer is only as precise as your printer. Mine was dead on (today). It should measure 8.3mm on a good day.

Mount the sensor on the bracket before attaching the bracket to the extruder carriage.

Use Repetier-Host, Cura, etc., to place the nozzle the thickness of a sheet of paper off the bed. Use the alignment widget to set the height of the sensor above the bed.

Some of the Marlin/SkynetV2.3.1 Configuration.h settings: (the others you can get from the manufacturer’s documentation)

I determined these two offsets using the grid file "Coords mm.pdf"

define X_PROBE_OFFSET_FROM_EXTRUDER 59 // X offset: -left +right [of the nozzle]

define Y_PROBE_OFFSET_FROM_EXTRUDER 14 // Y offset: -front +behind [the nozzle]

The Z_PROBE_OFFSET_FROM_EXTRUDER setting should be set based on your actual results you measure during setup.

define LEFT_PROBE_BED_POSITION 15

define RIGHT_PROBE_BED_POSITION 195

define BACK_PROBE_BED_POSITION 205

define FRONT_PROBE_BED_POSITION 25

If you use a non-standard servo pin you’ll need to define SERVO0_PIN. In my case it’s 27.

define SERVO0_PIN 27

DO NOT attempt to do an Auto Home after your very first upload. Send one of the test gcodes to make sure you're connected.

M280 P0 S10 ; pushes the pin down

M280 P0 S90 ; pulls the pin up

M280 P0 S120 ; Self test – keeps going until you do pin up/down or release alarm

M280 P0 S160 ; Release alarm

Hardware: (2) M3 x 8, (2) M3 x 12, (4) M3 nuts

Similar models

thingiverse

free

Anet A6 BLTouch/3DTouch mount (front) by thvranken

...isplay or with command m851) and saved to the eeprom (using the display or with command m500), in my case, this was around -2 mm.

thingiverse

free

Anet A8 3DTouch/BLTouch Auto Leveling Sensor Bracket by tobicothon

...thingiverse

mount this bracket on right bearing (bottom screws).

no need to change the screws

offset on marlin :

x = +58

y= +10

thingiverse

free

Anet A8 Moving Fan Bracket by twistedfab13

... 220

define x_min_pos -33

define y_max_pos 220

define y_min_pos -10

define z_max_pos 240

define z_min_pos 0

thingiverse

free

3D touch Black Anet A8 Left_Mount by zerone82

...ne z_min_endstop_inverting false

#define z_min_probe_endstop_inverting false

comment

//#define probe_manually

wiring as per image

thingiverse

free

Sensor Mount for Anet A8 by mulger

...0 // y offset: -front +behind [the nozzle]

//#define z_probe_offset_from_extruder 0 // z offset: -below +above [the nozzle]

thingiverse

free

Anet A8 Front Fan Sensor Mount 18 mm by buzzkc

...://www.thingiverse.com/thing:2506274

the wiring schematic and parts list for my sensor: https://www.thingiverse.com/thing:2758533

thingiverse

free

Back holder for Auto Level Anet by PgSerbia

...of the nozzle]

define y_probe_offset_from_extruder 63 // y offset: -front +behind [the nozzle]

define front_probe_bed_position 55

thingiverse

free

Anet A8 BLTouch Holder by jvyoralek

...e-homing

#define z_safe_homing

define servo

#define num_servos 1

if you spot any issues with item please let me know in comments.

thingiverse

free

Anet A8 Sensor Bracket 12mm and 18mm by Leo_N

...not sensor related but the z homing speed was too fast for my taste. to have it move slower use:

define homing_feedrate_z (4*60)

thingiverse

free

Anet A8 18mm Inductive sensor Bracket for Bowden carriage by joshhmann

...these settings.

define x_probe_offset_from_extruder -15//-25 //-21

define y_probe_offset_from_extruder -5//-29 //-43

Jmadison

thingiverse

free

2020 Extrusion Cable Clip by JMadison

...trusion cable clip by jmadison

thingiverse

simple cable clip used to keep cables in place when running through a 2020 extrusion.

thingiverse

free

Flat Cable Mounting Clip by JMadison

...clip by jmadison

thingiverse

used to secure two 10 conductor flat cables.

uses a single m3 flathead screw.

print without support

thingiverse

free

60mm Fan mount by JMadison

...an. no grill, only mounts to one side.

the fan mounting holes use 5mm fan screws. the 2 other mounting holes are for m3 screws.

thingiverse

free

DIRECTV Genie mini mounting bracket by JMadison

...genies and only the new model we got this year has this receptacle. the holes on the wall bracket are for #6/m3 flathead screws.

thingiverse

free

2020 Extrusion Cable Tie Mounts by JMadison

...hese are designed for cable ties less than 3mm wide.

the hole is for m3 flathead screws.

these should be printed without support.

thingiverse

free

UM2 Clone Power Switch Box by JMadison

...elf tapping flathead screws (other sizes will probably work)

snap in switch+receptacle: http://www.ebay.com/itm/like/221725745452

thingiverse

free

ABS Fume filter by JMadison

...strong fan to push air through the larger capacity version. i found a 67cfm fan (or so it claims). i'll see how it performs.

thingiverse

free

Anet A8 Switch Box by JMadison

...ck nuts (or regular and use locktite)

(2) m3 nuts

other:

i didn't remove the power supply to take the photos, i have a spare.

thingiverse

free

False Front Cabinet Clip by JMadison

...e project i’m building i needed 16 of them and i’m too cheap to buy them. this version is slightly less beefy than the original.

thingiverse

free

Ultimaker2 Clone Gantry Z Axis Top Remix by JMadison

... also makes it easier to ream the 12mm holes because the holes go all the way through.

the locking screws are m3 x 8 button head.

3Dtouch

thingiverse

free

3DTouch Holder by sopak

...3dtouch holder by sopak

thingiverse

universal 3dtouch and bltouch mount holes are 3mm with 5mm distance.

thingiverse

free

3DTouch binder by zull

...3dtouch binder by zull

thingiverse

platform for 3dtouch sensor from geeetech for geeetech i3 pro b with mk8 extruder

thingiverse

free

3DTouch Shield (Cover) by mardun

...e

shield/cover for 3dtouch to minimize led light. i tried to use other (mainly for bltouch) but they will not fit to my 3dtouch.

thingiverse

free

3DTouch model (STEP) by Leoliss

...retract - move needle in 3.8mm up. and yes, this is 3dtouch. bltouch have slightly different dimensions.

stl is just for preview.

thingiverse

free

GEEETech E3D v6 with 3DTouch by Minims

...geeetech e3d v6 with 3dtouch by minims

thingiverse

e3d v6 with 3dtouch for metal carriage

thingiverse

free

3dTouch probe model by deadcat

...e model by deadcat

thingiverse

this a fusion360 model of the 3dtouch to use when designing mounts. i have also included the stl.

thingiverse

free

3DTouch lock by markost

...he pin while printing and started breaking my prints and due potential damage to the sensor itself, i designed a pin lock for it.

thingiverse

free

BIQU B1 3DTouch mount by iNardex

...s not good for 3dtouch sensor.

designed for and tested with a 3dtouch v3.0.

i added the fusion360 project for any customizations.

thingiverse

free

Suport 3Dtouch BLTouch Graber Tec3d

...suport 3dtouch bltouch graber tec3d

thingiverse

suporte para fixar 3dtouch ou bltouch na extrusora graber i3 da tec3d.

thingiverse

free

3DTouch\BLTouch Holder for MiniTree T3 by zekeda1

...3dtouch\bltouch holder for minitree t3 by zekeda1

thingiverse

simple holder of 3dtouch\bltouch for minitree t3 3d printer.

Bltouch

thingiverse

free

Support bltouch by TonyJ

...support bltouch by tonyj

thingiverse

support bltouch

thingiverse

free

BLTOUCH for MICRON3DP by lamerhouse

...bltouch for micron3dp by lamerhouse

thingiverse

bltouch for micron3dp

thingiverse

free

SapphirePro mount for Bltouch

...sapphirepro mount for bltouch

thingiverse

sapphirepro mount for bltouch

thingiverse

free

ender6 BLtouch by chimaer

...ender6 bltouch by chimaer

thingiverse

ender6 bltouch

this is an external bracket

thingiverse

free

BLTouch KP3s by 1devilman1

...bltouch kp3s by 1devilman1

thingiverse

bltouch mount for kingroon kp3s

thingiverse

free

Bltouch support adjustable

...bltouch support adjustable

thingiverse

adjustable support for bltouch, p3steel.

thingiverse

free

BMG NEREUS BLTOUCH

...bmg nereus bltouch

thingiverse

petg

m3 screws and nuts for the bltouch

thingiverse

free

BLTouch Bracket by tidh666

...bltouch bracket by tidh666

thingiverse

serves to attach the bltouch sensor to the extruders

thingiverse

free

bltouch mount by wars

...bltouch mount by wars

thingiverse

reinforced bracket for bltouch cooperates with high_clearance_cr10_oem_fang_mod

thingiverse

free

BLTouch Holder by Jonthan06

...bltouch holder by jonthan06

thingiverse

support bltouch pour wanhao d12

A8

turbosquid

$47

Car A8

...

turbosquid

royalty free 3d model car a8 for download as max on turbosquid: 3d models for games, architecture, videos. (1196060)

turbosquid

$50

Audi A8

...yalty free 3d model audi a8 for download as 3dm, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1580187)

turbosquid

$15

Audi A8

...lty free 3d model audi a8 for download as obj, fbx, and blend on turbosquid: 3d models for games, architecture, videos. (1387519)

turbosquid

$500

Audi A8

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Audi A8 3D Model

...audi a8 3d model

3dexport

audi a8 cars car

audi a8 3d model ma 20351 3dexport

3d_export

$5

Audi A8 3D Model

...audi a8 3d model

3dexport

3d model of audi a8

audi a8 3d model badyaka 12136 3dexport

3d_ocean

$89

Audi A8 2010

...usiness car car class class f f german german luxury luxury s s s8 s8 sedan sedan vehicle vehicle

new audi a8 2010 detaled model.

turbosquid

$39

A8 2018

...a8 2018 for download as 3ds, obj, wrl, c4d, fbx, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1345349)

turbosquid

free

audi a8 l

...rbosquid

royalty free 3d model audi a8 l for download as obj on turbosquid: 3d models for games, architecture, videos. (1663016)

3d_ocean

$45

Audi A8 restyled

...our door vehicle was created in blender3d 2.62.realistic renderings were created with yafaray 0.1.2 realistic plugin.rendering...

Anet

thingiverse

free

Anet by derbodesign

...anet by derbodesign

thingiverse

logo anet

thingiverse

free

Anet e10 , Anet v1.0 by jonathan_943D

...anet e10 , anet v1.0 by jonathan_943d

thingiverse

soporte de ventilador de 80mm, para controladora anet v1.0

thingiverse

free

Anet A8 Anet AM8 Y belt holder

...anet a8 anet am8 y belt holder

thingiverse

anet a8 anet am8 y belt holder

thingiverse

free

Anet A8 Probe Bracket for anet sensor by chelrix

...anet a8 probe bracket for anet sensor by chelrix

thingiverse

anet a8 probe bracket for anet official sensor and marlin firmware

thingiverse

free

Anet logo by JUST3D_PRNTNG

...anet logo by just3d_prntng

thingiverse

anet logo

thingiverse

free

Fan nozzle for Anet A8 with original Anet levelsensor by peteruhlmann

...et levelsensor by peteruhlmann

thingiverse

here is an improved fan nozzle for the anet a8 with original level sensor from anet.

thingiverse

free

Anet Et4 Box

...anet et4 box

thingiverse

tool box for anet et4

thingiverse

free

Anet Logo by Superflex_Plastic_Fantastic

...anet logo by superflex_plastic_fantastic

thingiverse

anet logo to incorporate into designs.

thingiverse

free

Box for Anet ET4

...box for anet et4

thingiverse

this is a simple box for tool of anet et4

thingiverse

free

Anet V1.0 Board Kühlung (80mm Lüfter) / Anet A8 by MadCre8

...anet v1.0 board kühlung (80mm lüfter) / anet a8 by madcre8

thingiverse

anet v1.0 board kühlung (80mm lüfter) / anet a8

Sensor

3d_export

free

parking sensor

...parking sensor

3dexport

car parking sensor

turbosquid

$1

Sensor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Smoke sensor

...port

smoke sensor, can be an impressive element for your projects. easy to use, realistic image, low polygon, quality materials.

3d_export

$5

Air Quality Sensor v1

...air quality sensor v1

3dexport

air quality sensor v1

3d_export

$15

float sensor

...e up render. - all parts and materials are logically named. other formats ================= - collada (.dae) - autodesk fbx - obj

turbosquid

$26

Wind sensor C

...free 3d model wind sensor c for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328943)

turbosquid

$26

Wind sensor B

...free 3d model wind sensor b for download as 3ds, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1328168)

3d_export

$5

ultrasound sensor

...ivers convert ultrasound into electrical signals, and transceivers can both transmit and receive ultrasound. export in: -obj -fbx

3ddd

free

Вытяжка Shindo pallada sensor

... вытяжка

вытяжка shindo pallada sensor. в двух размерах - 600 и 900. текстуры в комплекте.

turbosquid

$52

Wind sensor A B C

...

royalty free 3d model wind sensor a b c for download as fbx on turbosquid: 3d models for games, architecture, videos. (1408406)

Auto

3d_export

$5

auto

...auto

3dexport

auto

3ddd

$1

auto

...auto

3ddd

max7

turbosquid

$69

AUTO

...to

turbosquid

royalty free 3d model auto for download as obj on turbosquid: 3d models for games, architecture, videos. (1453538)

3d_export

$10

Auto

...auto

3dexport

3d_export

free

auto

...auto

3dexport

3ddd

$1

Auto posters

...auto posters

3ddd

машина

auto posters

turbosquid

$50

auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$28

Auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

auto

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Bracket

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket 1 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel console

bracket 5 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel holder bracket

bracket 6 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel console

bracket 8 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket n280911 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

holder corbel bracket

bracket 9 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel holder bracket

bracket 10 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

corbel console bracket

bracket 11 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

holder console bracket

bracket 12 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bracket

...bracket

archibase planet

bracket corbel holder

bracket 13 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Leveling

design_connected

$11

Levels

...levels

designconnected

one nordic levels computer generated 3d model. designed by form us with love.

design_connected

$7

Level

...level

designconnected

zanotta level shelves and storage computer generated 3d model. designed by arik levy.

turbosquid

$29

level

...ty free 3d model level for download as 3ds, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1272856)

turbosquid

$1

level

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Mario level

...mario level

3dexport

mario level low quality for fun videos

3ddd

$1

LEVELS OF DISCOVERY

...етская мебель "levels of discovery". rab10003 princess mini rocker

кресло-качалка (мини) "принцесса навсегда"

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

turbosquid

$60

Desert level

...squid

royalty free 3d model desert level for download as fbx on turbosquid: 3d models for games, architecture, videos. (1208131)

turbosquid

$15

Transit Level

...quid

royalty free 3d model transit level for download as max on turbosquid: 3d models for games, architecture, videos. (1158112)

turbosquid

$14

Districts Level

...id

royalty free 3d model districts level for download as max on turbosquid: 3d models for games, architecture, videos. (1408410)