Thingiverse

Allison 1000 transmission by marcinszydlowski

by Thingiverse

Last crawled date: 4 years, 3 months ago

Hello everyone,

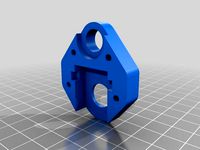

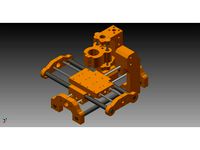

model presented here is a variation of Allison 1000 transmission derived from InterlinkKnight's 6 Speed Allison Automatic Transmission

It's operated manually by pushing/pulling breakes and shifting clutches. Model was designed for be assembled with bearings, Seeger rings, rods, shims and forming screws.

Gears and other parts have been prepared in Fusion 360 using paid add-in for generating planetary sets (available for Win and Mac).

In addition to the STL models there are also following documents:

assembly guide,

template for drilling holes in the support board (must be printed in 1:1 scale or scaled for the same factor as models if you'll do),

power flow, kinematic models and calculations of ratios,

sheet for calculating ratios for single stages.

Full video which shows it in action is on YouTube:

Main requirements

Type

Time/cost/dimensions

Notes

Printing time

77h

Assuming continuous operation (no breaks between parts) by one printer; in practice 1 week

Postprocessing time

4h

Removing supports, deburring, grinding

Cost of filament

$20

1 spool of 850g refill Fiberlogy Easy PLA if no other color used and success at first time

Cost of metal parts

$20

Cheapest parts found on the market

Assembling time

6h

Drilling holes in support plate, cutting grooves for Seeger rings on 8mm rod, cutting 8mm and 3mm rod

Dimensions (WxLxH)

28x44x16 cm

Printed parts

Name

Qty

01_Crank_placeholder.stl

1

02_Handle.stl

1

03_Knob.stl

1

04_Pointer.stl

1

05_C1_text.stl

1

06_C2_text.stl

1

07_C3_text.stl

1

08_C4_text.stl

1

09_C5_text.stl

1

10_P_text.stl

1

11_Input_shaft.stl

1

12_Bearing_support.stl

2

13_Clutch_rail_start_guide.stl

2

14_Clutch_rail_middle_guide.stl

1

15_P_support_back_bearing_lid.stl

4

16_P_support_front_bearing_lid.stl

4

17_Clutch_guide_front_bearing_lid.stl

2

18_Clutch_guide_back_bearing_lid.stl

2

19_P_support.stl

4

20_Clutch_support.stl

2

21_Break_teeth.stl

4

22_Break_support.stl

4

23_Break_handle_left_side.stl

4

23_Break_handle_right_side.stl

4

24_P5_planet.stl

4

25_P4_planet.stl

4

26_P3_planet.stl

4

27_P5_Synchronizer.stl

1

28_P4-P5_Synchronizer.stl

1

29_Clutch_1.stl

1

30_Clutch_2.stl

1

31_P3_sun.stl

1

32_P3_ring.stl

1

33_P4_ring.stl

1

34_P5_ring.stl

1

35_P4_P5_sun.stl

1

36_Output_carrier.stl

1

Metal parts

Name

Qty

Rod 8/297mm

1

Rod 8/95mm

2

Rod 3/20mm

4

Rod 3/14mm

4

Rod 3/41mm

12

Set screw 6/6mm

1

Set screw 8/8mm

1

Forming screw 3/12mm

40

Forming screw 4/20mm

4

Seeger external ring 8mm

4

Seeger external ring 20mm

4

Seeger internal ring 15mm

2

Seeger internal ring 48mm

2

Ball bearing 8x22x7mm

14

Ball bearing 20x47x14mm

2

Needle bearing 8x12x12mm

3

Needle bearing 20x26x20mm

1

Shim 3mm

24

Others

Name

Qty

Board or plate for support no smaller than 44x28x1cm

1

Tools

Name

Used for

Upholstery knife

removing supports, finishing surfaces

Pliers

removing supports

File

finishing surfaces

Drill (for steel) 8mm

deburring 8mm holes

Drill (for steel or wood) 2mm

drilling holes for forming screws in support board

Allen screwdriver 3mm

set screw in synchronizer C1

Allen screwdriver 4mm

set screw in sun P4-P5

Phillips screwdriver 3mm

forming screws 3x12mm

Phillips screwdriver 4mm

forming screws 4x20mm

External and internal Seeger calipers

mounting Seeger rings

Silicon or machine oil

lubricating parts

Grease

lubricating internal shaft's bearings

Tweezers

easier putting shims on planets' shafts

Recommendations

3D-printing settings

All models available here are oriented in a way which guarantee quite good quality in FDM technology. However, it's not enought to be sure that parts will be matched together when slicer use automatic settings. I strongly suggest to use advanced slicers like Cura, Prusa Slicer or any other which lets you to set:

elephant foot compensation (in Prusa Slicer)

Linear Advance (for my case K=0.04 or K=40 was ok),

horizontal expansion (hole, initial layer, general - in Cura),

support types and orientation

Metal parts

Bearings, screws, shims and Seeger rings can be cheapest but in case of rods you need to be sure that theirs diameters are exact. In other case, you can waste a few hours for grinding 8mm rod for be able to put 8mm needle and ball bearings on them or making 3mm holes in plastic parts slightly bigger.

Known problems

Assembly

breaks aren't designed well for beeing both assembled or disassembled - try to follow the assembly guide for putting these parts together,

mounting planets into carriers - unfortunately it's the worst thing here (I realized too late) and it's a one-way operation; it cannot be reversed and for removing shaft, carrier needs to be damaged; you need a thin tweezers, knife, screwdriver or similar kind of tool and be very patient for putting shaft throught the carrier, shim, planet and the last shim

mounting bearings is (and generally, should be) tight but try to pushing them rather than hitting by hammer; you need to be careful for not breaking parts,

internal Seeger rings (15 and 48mm) requires strong calipers - cheapest sets of calipers may be unable and dangerous to bend rings of those sizes (wear safety gogles for mounting snap rings)

Operating

shifting clutches may be difficult especially for overdrives or for some othe configuration of switches. If so, try to do this by pushing clutches instead of C1/C2 shifts;

4th and 5th gear (overdrives) requires more forces and for synchronizers designed for this model' design it tends to shifting clutch C2 back - it need to be hold during spinning the input shaft.

model presented here is a variation of Allison 1000 transmission derived from InterlinkKnight's 6 Speed Allison Automatic Transmission

It's operated manually by pushing/pulling breakes and shifting clutches. Model was designed for be assembled with bearings, Seeger rings, rods, shims and forming screws.

Gears and other parts have been prepared in Fusion 360 using paid add-in for generating planetary sets (available for Win and Mac).

In addition to the STL models there are also following documents:

assembly guide,

template for drilling holes in the support board (must be printed in 1:1 scale or scaled for the same factor as models if you'll do),

power flow, kinematic models and calculations of ratios,

sheet for calculating ratios for single stages.

Full video which shows it in action is on YouTube:

Main requirements

Type

Time/cost/dimensions

Notes

Printing time

77h

Assuming continuous operation (no breaks between parts) by one printer; in practice 1 week

Postprocessing time

4h

Removing supports, deburring, grinding

Cost of filament

$20

1 spool of 850g refill Fiberlogy Easy PLA if no other color used and success at first time

Cost of metal parts

$20

Cheapest parts found on the market

Assembling time

6h

Drilling holes in support plate, cutting grooves for Seeger rings on 8mm rod, cutting 8mm and 3mm rod

Dimensions (WxLxH)

28x44x16 cm

Printed parts

Name

Qty

01_Crank_placeholder.stl

1

02_Handle.stl

1

03_Knob.stl

1

04_Pointer.stl

1

05_C1_text.stl

1

06_C2_text.stl

1

07_C3_text.stl

1

08_C4_text.stl

1

09_C5_text.stl

1

10_P_text.stl

1

11_Input_shaft.stl

1

12_Bearing_support.stl

2

13_Clutch_rail_start_guide.stl

2

14_Clutch_rail_middle_guide.stl

1

15_P_support_back_bearing_lid.stl

4

16_P_support_front_bearing_lid.stl

4

17_Clutch_guide_front_bearing_lid.stl

2

18_Clutch_guide_back_bearing_lid.stl

2

19_P_support.stl

4

20_Clutch_support.stl

2

21_Break_teeth.stl

4

22_Break_support.stl

4

23_Break_handle_left_side.stl

4

23_Break_handle_right_side.stl

4

24_P5_planet.stl

4

25_P4_planet.stl

4

26_P3_planet.stl

4

27_P5_Synchronizer.stl

1

28_P4-P5_Synchronizer.stl

1

29_Clutch_1.stl

1

30_Clutch_2.stl

1

31_P3_sun.stl

1

32_P3_ring.stl

1

33_P4_ring.stl

1

34_P5_ring.stl

1

35_P4_P5_sun.stl

1

36_Output_carrier.stl

1

Metal parts

Name

Qty

Rod 8/297mm

1

Rod 8/95mm

2

Rod 3/20mm

4

Rod 3/14mm

4

Rod 3/41mm

12

Set screw 6/6mm

1

Set screw 8/8mm

1

Forming screw 3/12mm

40

Forming screw 4/20mm

4

Seeger external ring 8mm

4

Seeger external ring 20mm

4

Seeger internal ring 15mm

2

Seeger internal ring 48mm

2

Ball bearing 8x22x7mm

14

Ball bearing 20x47x14mm

2

Needle bearing 8x12x12mm

3

Needle bearing 20x26x20mm

1

Shim 3mm

24

Others

Name

Qty

Board or plate for support no smaller than 44x28x1cm

1

Tools

Name

Used for

Upholstery knife

removing supports, finishing surfaces

Pliers

removing supports

File

finishing surfaces

Drill (for steel) 8mm

deburring 8mm holes

Drill (for steel or wood) 2mm

drilling holes for forming screws in support board

Allen screwdriver 3mm

set screw in synchronizer C1

Allen screwdriver 4mm

set screw in sun P4-P5

Phillips screwdriver 3mm

forming screws 3x12mm

Phillips screwdriver 4mm

forming screws 4x20mm

External and internal Seeger calipers

mounting Seeger rings

Silicon or machine oil

lubricating parts

Grease

lubricating internal shaft's bearings

Tweezers

easier putting shims on planets' shafts

Recommendations

3D-printing settings

All models available here are oriented in a way which guarantee quite good quality in FDM technology. However, it's not enought to be sure that parts will be matched together when slicer use automatic settings. I strongly suggest to use advanced slicers like Cura, Prusa Slicer or any other which lets you to set:

elephant foot compensation (in Prusa Slicer)

Linear Advance (for my case K=0.04 or K=40 was ok),

horizontal expansion (hole, initial layer, general - in Cura),

support types and orientation

Metal parts

Bearings, screws, shims and Seeger rings can be cheapest but in case of rods you need to be sure that theirs diameters are exact. In other case, you can waste a few hours for grinding 8mm rod for be able to put 8mm needle and ball bearings on them or making 3mm holes in plastic parts slightly bigger.

Known problems

Assembly

breaks aren't designed well for beeing both assembled or disassembled - try to follow the assembly guide for putting these parts together,

mounting planets into carriers - unfortunately it's the worst thing here (I realized too late) and it's a one-way operation; it cannot be reversed and for removing shaft, carrier needs to be damaged; you need a thin tweezers, knife, screwdriver or similar kind of tool and be very patient for putting shaft throught the carrier, shim, planet and the last shim

mounting bearings is (and generally, should be) tight but try to pushing them rather than hitting by hammer; you need to be careful for not breaking parts,

internal Seeger rings (15 and 48mm) requires strong calipers - cheapest sets of calipers may be unable and dangerous to bend rings of those sizes (wear safety gogles for mounting snap rings)

Operating

shifting clutches may be difficult especially for overdrives or for some othe configuration of switches. If so, try to do this by pushing clutches instead of C1/C2 shifts;

4th and 5th gear (overdrives) requires more forces and for synchronizers designed for this model' design it tends to shifting clutch C2 back - it need to be hold during spinning the input shaft.

Similar models

3dwarehouse

free

Solarbotics 1-1/4' Wheel, Internal Set-screw

...ics 1-1/4' wheel, internal set-screw

3dwarehouse

aluminum hub with 3mm shaft and setscrew covered by the grippy rubber tire.

thingiverse

free

8mm bearing mount for 12mm Linear Rail support + 8mm Lead Screw by elufo

... x m3 nuts

bearings: 8mm inner, 16mm outer, 5mm thickness.

12mm linear shaft.

8mm lead screw.

nema 23 support + 10mm height base.

thingiverse

free

Spur Gears: 1 to 2 Ratio for 1/4" or 8mm shaft by Cotton80

...an easy fit.

the large gear has 28t and the small gear has 14t.

added on 02/05/2017: gears together for 1/4" & 8mm shaft

thingiverse

free

Spoolholder recycling by djdj111

...cut into two pieces each) or ball bearings. plug the parts together and enjoy this simple spoolholder. use big or small shims ;-)

thingiverse

free

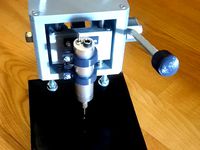

PCB Drill Press by Mape

...that works great. i recommend using this one (or similar instead of the small drill. this drill has a...

thingiverse

free

Magnetic Slip Clutch for movie reels (6mm D-shaft to 8mm square shaft) by Agumander

...r 1/4"-20 threads will be handy, and your choice of adhesive. i used a hot glue gun but super glue would probably be easier.

thingiverse

free

U-STAR Mini Bench Saw UA-90400 Bearing Block by Van_Houten

... countersunk for the bearing block screws.

1.5mm hex screwdriver for the brass motor coupler and a screwdriver for the 3mm screws

thingiverse

free

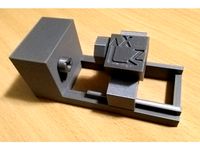

cncDIY by tonyhoang

...arduino cnc shield

3 a4988

1 relay (on/off spindle)

and something you need to assembly.

firmware: grbl v0.9j

control: grblcontrol

thingiverse

free

"Doubowden" Double Hobbed Bolt Bowden Extruder Assembly by MatGyver85

...pression springs for idlers. not sure what size exactly.

2 - 8mm x 15mm drill rod (5/16" may work)

1 - nema 17 stepper motor

thingiverse

free

Shaft Hub by LabRecon

...an element, such as a disk, to a shaft. it was designed for a 1/4" shaft and includes a hole to accommodate a #2 set screw.

Marcinszydlowski

thingiverse

free

CNC lathe kinematic model by marcinszydlowski

...:

name

qty

notes

body

1

support z

1

with supports

support x

1

with supports

chuck

1

turret

1

with supports

3x12mm forming screw

2

thingiverse

free

Spool for refill filament coils by marcinszydlowski

...d for printing (100% speed, 0.2mm layer height):

left side: 13.5 hours,

right side: 12 hours

there's no post-printing needed.

thingiverse

free

Self-centering 3-jaws lathe chuck by marcinszydlowski

...trength

4x30mm allen bolt

6

for jaws and blocking pinion keys

4x12mm allen bolt

3

for jaws

4x12/15mm allen csk

3

for internal lid

Allison

3d_export

$17

porada allison

...render, it is recommended to install a version of at least 1.5, since the glossiness of materials is configured with pbr in mind.

archive3d

free

Sconce 3D Model

...sconce 3d model archive3d sconce lamp-bracket lantern sconce allison n210511 - 3d model (*.3ds) for interior 3d...

3d_export

$155

Lockheed P38 Lightning My little Pig 3D Model

...1943, which had a more powerful version of the allison v-1710 engine.the p-38j, introduced in august 1943, was considerably...

thingiverse

free

Allison Kelly- Remix by akelly141

...allison kelly- remix by akelly141

thingiverse

allison kelly- remix

thingiverse

free

Allison's House by alr112

...allison's house by alr112

thingiverse

this is a model of my house.

thingiverse

free

ceramic robot allison veldheer by massink

...ceramic robot allison veldheer by massink

thingiverse

scanned with the makerbot digitizer desktop 3d scanner

thingiverse

free

Allison Leonard by Friends

...s, artists, diyers, makers, musicians, hackers and anybody else we think is notable.

made with a polhemus 3d scanner at makerbot.

blendswap

free

Allison House Style Illustration Fog

...utput you're looking for.i hope this isn't copyright infringing - for what it's worth, she knows about / endorsed it.

3dbaza

$3

Allison Industrial Loft Vintage Brass Pendant (137152)

... 888<br>xform: no<br>box trick: no<br>model parts: 2<br>render: v-ray<br>formats: 3ds max 2014, obj

thingiverse

free

Allison Kelly-Elegant Geometry by akelly141

...of it. each of the horizontal cylinders have rings coming off them. the idea here was to make them look as if they were balanced.

Transmission

archibase_planet

free

Transmission tower

...lectricity pylon lattice tower framework tower

transmission tower n121015 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

design_connected

$13

Transmission Sculpture Chandelier

...ture chandelier

designconnected

lasvit transmission sculpture chandelier computer generated 3d model. designed by studio deform.

archive3d

free

Transmission tower 3D Model

...mework tower

transmission tower n121015 - 3d model (*.gsm+*.3ds) for exterior 3d visualization.

3ddd

$1

Lasvit Transmission Торшер

...ry angle. glass parts are joined by heat, creating individual elements that become one material and one body.

приятных рендеров)

3ddd

$1

Lasvit Transmission люстры

...ry angle. glass parts are joined by heat, creating individual elements that become one material and one body.

приятных рендеров)

3d_export

$70

Fiat Van for radio transmission 3D Model

...ansmission 3d model

3dexport

fiat van truck radio transmission

fiat van for radio transmission 3d model neutrino76 54272 3dexport

3d_export

$1000

Automobile Manual Transmission mechanism Gearbox 3D Model

...ox 3d model

3dexport

transmission gearbox

automobile manual transmission mechanism gearbox 3d model daveterminator 24996 3dexport

3d_export

$299

Engine with Transmission 3D Model

... truck turbo 6v transverse four cylinder auto mobile car clutch crank 16v

engine with transmission 3d model fly123 89978 3dexport

cg_studio

$45

Wiper with transmission and drive unit3d model

...c4d .lwo .obj - wiper with transmission and drive unit 3d model, royalty free license available, instant download after purchase.

3d_export

$319

Engine with Transmission Exhaust 3D Model

...sverse four cylinder pipe exhaust car clutch crank 16v mitsubishi

engine with transmission exhaust 3d model fly123 89987 3dexport

1000

3d_export

free

stone 1000

...stone 1000

3dexport

3ddd

$1

Ippon AVR-1000

...ippon avr-1000

3ddd

стабилизатор , ippon

стабилизатор напряжения ippon avr-1000

3ddd

$1

Faraway Tree - 1000

...ddd

faraway tree , willowlamp

люстра от компании willowlamp. модель faraway tree - 1000.

3ddd

free

table 1000

... stool , table , greek

www.tsinos.gr

3d_export

$5

superbike s 1000 rr

...superbike s 1000 rr

3dexport

superbike s 1000 rr, motorcycle with perfect model.

3d_export

$89

Wolseley 1000 3D Model

...ini wolseley 1000 mk1 classic british austin morris 1962 1965 cooper old antique

wolseley 1000 3d model desmonster 98084 3dexport

3ddd

$1

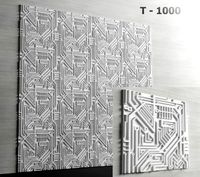

3д Панель - T-1000

...3д панель - t-1000

3ddd

панель

стеновая, гипсовая 3д панель t-1000.

500 x 500 мм.

design_connected

$16

1000 Karat Blau Pendant

...00 karat blau pendant

designconnected

ingo maurer 1000 karat blau pendant computer generated 3d model. designed by schmid, axel.

3ddd

$1

NorSap 1000 Series

...norsap 1000 series

3ddd

pilot chair , norsap

texture included

3d_export

$35

Swimex 1000S 3D Model

...swimex 1000s 3d model

3dexport

swimex swimming pool therapy water swim spa

swimex 1000s 3d model artet 33413 3dexport