Thingiverse

All year round Solar garden light by Lodestone

by Thingiverse

Last crawled date: 2 years, 12 months ago

I was motivated to design this solar light because I was fed up with the poor performance from commercial lights.

The solar panel is one watt and the battery storage is a 10Ah rechargeable D cell. I'm using a 100uH inductor which gives 10mA into the LED and 33mA drain from the cell this gives a very adaqate light and the LED is very over rated for the job so long life and low phosphor degradation will hopefully be the outcome.

The chip used is a QX5252F this is commonly available from eBay an this wonderfully pragmatic design which has other uses I'm sure, here is the data sheet which is not comprehensive. http://www.mikrocontroller.net/attachment/158139/QX5252.pdf

The solar cells in the round design are very old monocrystalline cells they are very thick and hard to break and easy to work with I have hundreds of them, I realise this is not fare on you and have produced two alternative panels with modern cells which can be obtained from eBay.

There are two types; 19mm x 52mm cells two series banks of four connected in parallel to give two volts at 500mA. And ; 38mm x 52mm cells connected in series to give two volts at 500mA. I have tried both options some skill is required when soldering these cells as they are VERY easy to break. There are encapsulated cells 53mm x 18mm which I have not tried which in theory would fit but only give half the output.

The Perspex top is 4-5mm thick and is easily bent to shape with a hot air paint stripper the shape does serve some purpose as this diffracts and reflects light around. This would work with a plane square top but not be so effective. The Perspex top is glued with epoxy to the panel and the body is fixed to the panel with acetone for ABS (which I am using) and epoxy for PLA (don't know how long this lasts outside).

I have made channels in all the parts to accommodate the wiring and make it easy to assemble without a PCB which maybe novel I'm not sure and would not want to steel any credit.

The D cell holder has extra pads on the corners to stop it lifting and bridging supports on the socket groove all need removing.

The negative contact on the D cell is just a strip of phosphor bronze .2mm thick. I had some knocking around but I see that Rapid sells it.

The spike is a piece of 8mm stainless steel but a bit of zinc plated studding would do if that's what you have.

The connectors I have used are turned pin header and socket which comes in strips and can be cut to size. The output I have plugged onto the end of the LED wires as a plug seemed an unnecessary luxury.

Ill include lots of pictures which I hope will help with construction but please ask if you would like to make one and you have issues.

PS

The funny L shape on the Large square panel is an insulator as one tabbing strip passes over the other.

The solar panel is one watt and the battery storage is a 10Ah rechargeable D cell. I'm using a 100uH inductor which gives 10mA into the LED and 33mA drain from the cell this gives a very adaqate light and the LED is very over rated for the job so long life and low phosphor degradation will hopefully be the outcome.

The chip used is a QX5252F this is commonly available from eBay an this wonderfully pragmatic design which has other uses I'm sure, here is the data sheet which is not comprehensive. http://www.mikrocontroller.net/attachment/158139/QX5252.pdf

The solar cells in the round design are very old monocrystalline cells they are very thick and hard to break and easy to work with I have hundreds of them, I realise this is not fare on you and have produced two alternative panels with modern cells which can be obtained from eBay.

There are two types; 19mm x 52mm cells two series banks of four connected in parallel to give two volts at 500mA. And ; 38mm x 52mm cells connected in series to give two volts at 500mA. I have tried both options some skill is required when soldering these cells as they are VERY easy to break. There are encapsulated cells 53mm x 18mm which I have not tried which in theory would fit but only give half the output.

The Perspex top is 4-5mm thick and is easily bent to shape with a hot air paint stripper the shape does serve some purpose as this diffracts and reflects light around. This would work with a plane square top but not be so effective. The Perspex top is glued with epoxy to the panel and the body is fixed to the panel with acetone for ABS (which I am using) and epoxy for PLA (don't know how long this lasts outside).

I have made channels in all the parts to accommodate the wiring and make it easy to assemble without a PCB which maybe novel I'm not sure and would not want to steel any credit.

The D cell holder has extra pads on the corners to stop it lifting and bridging supports on the socket groove all need removing.

The negative contact on the D cell is just a strip of phosphor bronze .2mm thick. I had some knocking around but I see that Rapid sells it.

The spike is a piece of 8mm stainless steel but a bit of zinc plated studding would do if that's what you have.

The connectors I have used are turned pin header and socket which comes in strips and can be cut to size. The output I have plugged onto the end of the LED wires as a plug seemed an unnecessary luxury.

Ill include lots of pictures which I hope will help with construction but please ask if you would like to make one and you have issues.

PS

The funny L shape on the Large square panel is an insulator as one tabbing strip passes over the other.

Similar models

thingiverse

free

DIY 6w Solar Charger by EpicHardware

...d in parallel and the maximum they can supply is about 550ma at 9v which then you can use a dc to dc step down converter to 5v.

thingiverse

free

Linear Bearing Mounted Light Bar by GopherRancher

...me on when the printer is powered up. the current draw is very small so there will not be any noticeable effect on the fan speed.

grabcad

free

48 volt solar panel

...48 volt solar panel

grabcad

48 volt solar panel 5 amps output

thingiverse

free

Front LED Light by Yaxisme

...der the hotend so i came up with this. i just used some led strip and a xt60 splitter and male xt60 to wire it up to the 24 volt.

thingiverse

free

LED holder for my LED Strips based on Thing 1194640 by FruehStuC

...me a 12v supply for an auxiliary fan. i placed this where it would get the benefit of air flow from the stepper motor driver fan.

cg_trader

free

Solar Panel for LED Light Bottle Design Challenge

...pecific dimensions would be nice. bottle light led design solar panel challenge solar panel led light electronics other led light

thingiverse

free

Anet A8 Extended duct with LED strip bracket by richardtracy

...

also the duct corners will start to warp up. i kind of like it that way (it gives it more of a bowl effect), but just a warning.

thingiverse

free

panel face plate for atx power supply by irondmax

...e 12 volt output, and also have outputs for the 5 volt and 3 volt. i will not use the -12 volt

mainly this is for my 3d printer

3dwarehouse

free

Semi Transparent Solar Panel (156 kb)

... light shining through, semi-shade. this model is based on some solar panels i have seen. i have no idea what its power would be.

thingiverse

free

Foldable Solar Panel - Large version by enif

...r cable is for usb charging and just recombines the voltages of the three cells in parallel and ends in a usb charging connector.

Lodestone

thingiverse

free

Queen Marking press-in-cage by Lodestone

...of the old super glue.

and there you have it a press in cage made from stuff you have quicker than ordering or going to the shop.

thingiverse

free

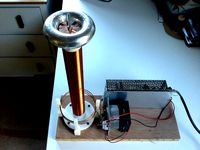

Tesla coil using simple Slayer exciter by Lodestone

...

you may have allot of fun exceeding the performance of what i have suggested yourself but i offer this as a good starting point.

3dwarehouse

free

Lodestone Trench Grate

...lodestone trench grate

3dwarehouse

3dwarehouse

free

Building in Elk Grove, CA 95624, USA

...building in elk grove, ca 95624, usa 3dwarehouse lodestone ...

3dwarehouse

free

Building in Elk Grove, CA 95624, USA

...building in elk grove, ca 95624, usa 3dwarehouse lodestone ...

Solar

3d_ocean

$4

Solar Panel

...solar panel

3docean

cell panel solar

fully textured solar panel with scaleable solar cells.

3ddd

$1

solar cell

...solar cell

3ddd

солнечная батарея

solar cell

3d_export

$7

Solar Panel

...solar panel

3dexport

perfect solar panel for roof, modular, extensible.

3d_export

$5

solar system

...solar system

3dexport

solar system in c4d, with 8k nasa textures

3d_export

$15

solar system

...nd the other the sun, the earth and the moon, the latter has an animation with camera movement included, the files are in spanish

3ddd

$1

Zumtobel Solar II

...obel solar ii

3ddd

zumtobel , solar

модель направленного светильника solar 2 от zumtobel

3d_ocean

$14

Solar Panels

... materials, hdri map, vray gi setup. four solar panels: type1: 1849 – poly, 2035 – vert. type2: 954 – poly, 1051 – vert. type3...

turbosquid

$29

Solar System

...squid

royalty free 3d model solar system for download as fbx on turbosquid: 3d models for games, architecture, videos. (1236050)

turbosquid

$25

Solar Panel

...osquid

royalty free 3d model solar panel for download as max on turbosquid: 3d models for games, architecture, videos. (1516562)

turbosquid

$25

Solar System

...uid

royalty free 3d model solar system for download as blend on turbosquid: 3d models for games, architecture, videos. (1314058)

Garden

3d_export

$18

garden-garden-tree 60

...garden-tree 60<br>executed in 3d max 2014<br>all textures and materials needed for the rendering found in the archive

3d_export

$18

garden-garden-tree 41

...garden-tree 41<br>executed in 3d max 2014<br>all textures and materials needed for the rendering found in the archive

3d_export

$18

garden-garden-tree 58

...garden-tree 58<br>executed in 3d max 2014<br>all textures and materials needed for the rendering found in the archive

3d_export

$18

garden-garden-tree 59

...garden-tree 59<br>executed in 3d max 2014<br>all textures and materials needed for the rendering found in the archive

3d_export

$18

garden-garden-tree 56

...garden-tree 56<br>executed in 3d max 2014<br>all textures and materials needed for the rendering found in the archive

3d_export

$18

garden-garden-tree 57

...garden-tree 57<br>executed in 3d max 2014<br>all textures and materials needed for the rendering found in the archive

turbosquid

$1

garden

...

turbosquid

royalty free 3d model garden for download as max on turbosquid: 3d models for games, architecture, videos. (1167978)

3d_export

$6

roof garden furniture seating and garden set

...roof garden furniture seating and garden set

3dexport

roof garden furniture seating and garden set

3d_export

$25

garden swing

...garden swing

3dexport

garden swing

3d_export

$12

Modern garden

...modern garden

3dexport

modern garden

Year

turbosquid

$29

New Year

...urbosquid

royalty free 3d model new year for download as max on turbosquid: 3d models for games, architecture, videos. (1483853)

3ddd

$1

DDD NEW YEAR

...ddd new year

3ddd

3ddd new year

3ddd

$1

DDD NEW YEAR

...ddd new year

3ddd

3ddd new year

3d_export

$5

new year

...new year

3dexport

3d_export

$5

new year

...new year

3dexport

3d_ocean

$4

New Year

...vray it come with these file 3dsmax 2016 2015 2014 2013 maya 2016 obj blender c4d stl for 3d print 3ds fbx keyshot happy new year

3d_ocean

$4

New Year

...vray it come with these file 3dsmax 2016 2015 2014 2013 maya 2016 obj blender c4d stl for 3d print 3ds fbx keyshot happy new year

3d_ocean

$4

New Year

...vray it come with these file 3dsmax 2016 2015 2014 2013 maya 2016 obj blender c4d stl for 3d print 3ds fbx keyshot happy new year

3d_ocean

$4

New Year

...vray it come with these file 3dsmax 2016 2015 2014 2013 maya 2016 obj blender c4d stl for 3d print 3ds fbx keyshot happy new year

3d_ocean

$4

New Year

...vray it come with these file 3dsmax 2016 2015 2014 2013 maya 2016 obj blender c4d stl for 3d print 3ds fbx keyshot happy new year

Round

turbosquid

$18

round chairs with round table

...und chairs with round table for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1454090)

3d_export

$5

round knob

...round knob

3dexport

round knob

3d_export

$5

Italian round table Millennium Round

...italian round table millennium round

3dexport

3ddd

$1

Round Ottoman

...round ottoman

3ddd

пуф

round ottoman

3ddd

$1

Round pillow

...round pillow

3ddd

подушка

round pillow

3ddd

free

Round bed

...round bed

3ddd

круглая

round bed

3ddd

$1

round table

...round table

3ddd

круглый

round table, стол

3ddd

free

ROUND TABLE

...round table

3ddd

журнальный , круглый

round table

3ddd

$1

Round Table

...round table

3ddd

круглый , кофейный

rounded coffee table

3ddd

$1

Round Rug

...round rug

3ddd

ковер , круглый

useful rounded rug

Light

archibase_planet

free

Light

...light

archibase planet

lamp lighting light

light - s2 - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

light luminaire lighting

light l0465 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

lighting

...lighting

3dexport

lighting

3d_export

$5

lighting

...lighting

3dexport

lighting in livingroom

turbosquid

$3

Lighting Tree with Lights

...d model lighting tree with lights for download as max and 3ds on turbosquid: 3d models for games, architecture, videos. (1585507)

archibase_planet

free

Light

...light

archibase planet

luster lighting solution

light - s - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

luster lamp lighting

light 1 - 3d model for interior 3d visualization.

archibase_planet

free

Lights

...lights

archibase planet

surgical lights surgical lamp

surgical lights (floor) - 3d model for interior 3d visualization.

archibase_planet

free

Light

...light

archibase planet

lighting luminaire candlelight

light l0463 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$18

street light-lighting-light-xia bing

...

3dexport

street light-lighting-light-xia bing<br>max 2015 v-ray 3 max 2015<br>textures<br>all files in zip...

All

turbosquid

$20

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

all

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$29

All-Two

...all-two

designconnected

bonaldo all-two computer generated 3d model. designed by bicego, sergio.

design_connected

$29

All-One

...all-one

designconnected

bonaldo all-one computer generated 3d model. designed by bicego, sergio.

design_connected

$16

Holly All

...holly all

designconnected

serralunga holly all computer generated 3d model. designed by starck, philippe.

3d_export

$15

all terrain

...all terrain

3dexport

turbosquid

$15

ALL SHIP

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$2

Bodema. All in. Sofa

... all in , угловой

bodema. all in. sofa

size: 290x160x103

3ddd

$1

holly all

...holly all

3ddd

philippe starck

http://www.starck.com/en/design/categories/furniture/chairs.html#holly_all

design_connected

$27

All-Two Meridiana

...all-two meridiana

designconnected

bonaldo all-two meridiana computer generated 3d model. designed by bicego, sergio.