Thingiverse

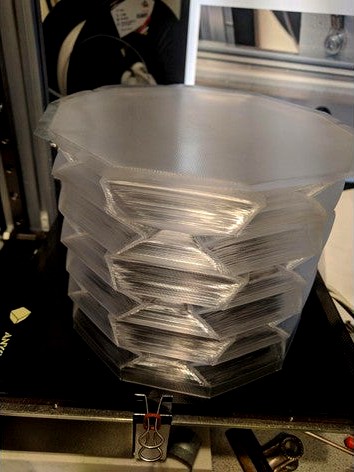

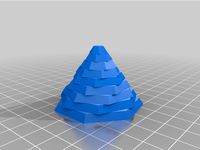

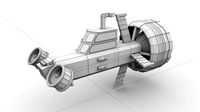

Air Bellows origami structure by peter120

by Thingiverse

Last crawled date: 4 years ago

Air bellows that folds along the inner edges origami style as it compresses so PP is the filament of choice.

Slice and print in Vase mode. I used prusa slicer to create the gcode for my cetus printer that has a 0.4mm nozzle. Slice with a 0.2mm layer, 0.6mm paving width, 8mm brim, and the default 3 layer center for the vase bottom is fine (the design is an open tube at both ends), this becomes the top bellows seal. This print is thin and weighs about 35 gr. I printed the PP at 255C to reduce sideways extrusion forces during layer printing. Layer adhesion is great using fan print cooling and no heated chamber. My glass build surface was 60 to 80C. If the brim lifts use some packing tape on the bed. Also to speed up initial test prints I set the slicer bottom to zero layers and then stop the print after the first full fold to inspect all the folding edges for weak spots or holes. Adjust the slicer settings and test print again. When you think you have the correct slicer settings add back the 3 bottom layers in the slicer and go for it.

3D printer air pump conversion?

The print takes about 3 kg or 5 lbs of force to compress and the full stroke has a volume of about 2 liters. 3D printers with Z axis threads should be capable of compressing this bellows if mounted on the build plate. My printer uses a Z axis belt so the force is limited to under 2 lbs and no joy for me.

The 10 sided open end needs a custom thing with intake and exhaust reed valves. PP shrinks on cooling and my bellows measures 144 mm across the flats. For attaching the your custom thing I would think some packing tape or a cable tie or both.

stay safe

-Peter

Slice and print in Vase mode. I used prusa slicer to create the gcode for my cetus printer that has a 0.4mm nozzle. Slice with a 0.2mm layer, 0.6mm paving width, 8mm brim, and the default 3 layer center for the vase bottom is fine (the design is an open tube at both ends), this becomes the top bellows seal. This print is thin and weighs about 35 gr. I printed the PP at 255C to reduce sideways extrusion forces during layer printing. Layer adhesion is great using fan print cooling and no heated chamber. My glass build surface was 60 to 80C. If the brim lifts use some packing tape on the bed. Also to speed up initial test prints I set the slicer bottom to zero layers and then stop the print after the first full fold to inspect all the folding edges for weak spots or holes. Adjust the slicer settings and test print again. When you think you have the correct slicer settings add back the 3 bottom layers in the slicer and go for it.

3D printer air pump conversion?

The print takes about 3 kg or 5 lbs of force to compress and the full stroke has a volume of about 2 liters. 3D printers with Z axis threads should be capable of compressing this bellows if mounted on the build plate. My printer uses a Z axis belt so the force is limited to under 2 lbs and no joy for me.

The 10 sided open end needs a custom thing with intake and exhaust reed valves. PP shrinks on cooling and my bellows measures 144 mm across the flats. For attaching the your custom thing I would think some packing tape or a cable tie or both.

stay safe

-Peter

Similar models

thingiverse

free

Hydroponic basket cup parametric by OneLine

... oneline

thingiverse

print in vase mode. use 0 layers bottom. you can use the slicer brim support to add a lip/brim to your cup.

thingiverse

free

Z-axis screw protection by AlexKayman

...ust. just put it and forget, it moves on the gantry freely.

9mm hole. 22mm height. print in vase mode, 0 bottom layers, use brim.

thingiverse

free

Bed Leveling Circle and Boxes by Latency

...xis adjustment is dialed-in correctly. it contains only 1 layer and should print in around 12 minutes using basic slicer settings

thingiverse

free

Air Gauge Holder by sds5150

...olster-wall mountable

no supports necessary.

i do use a brim

pla

200/65 1st layer

190/60 remaining

sliced with prusa slicer

thingiverse

free

Z Axis Calibration by Breakology

...z axis due to some odd layer shifting. this thing is about 60mm high. look for layer shift in your z axis, uses minimal material.

thingiverse

free

Tronxy X5SA Z axis holder by pvpeev

...is guides in place at the top, so you can put only the bottom screw. you need to print a set of 4 parts to customise the printer.

thingiverse

free

Vase #005 by Snakedad

...sed at top/bottom, so [insert slicer name] will complain about model not being manifold. will print just fine. slice and preview.

grabcad

free

Vase with twisted knurls

... and choose to print a bottom or no bottom. i used an old glass as inner and fluid tight part, so i 3d printed it without bottom.

thingiverse

free

Bottom Tray for use with Ender 3 Squashball Feet

...n the slicer if there is less height required.

no magic settings required. i printed with supports under the start of the handle.

thingiverse

free

parametric mendel z-axis top holder by BonsaiBrain

...earing and the wobbling of the z-axis is nearly eliminated.

you can read more about it on: www.ifeelbeta.de

greetings

bonsaibrain

Peter120

thingiverse

free

File Holder by peter120

...he file handle diameter you own.

designed in fusion 360 and printed on a custom linear rail printer with duel electronics.

-peter

thingiverse

free

OXO tong handle by peter120

... used a stainless rivet that needs to be cut and is replaced by a 4-40 stainless bolt in the printed part.

designed in fusion 360

thingiverse

free

Mitutoyo Dial Indicator dovetail back by peter120

... how you like to measure. the angle back has enough clearance for my indicator mount but it is not a universal.

stay safe

-peter

thingiverse

free

Belt alignment by peter120

...sing no fan for better layer strength.

designed with fusion 360 and printed on a modified cr10s pro with duet2 wi-fi electronics.

thingiverse

free

Drip irrigation by peter120

...re 10-32 for attaching to the raindrip sprayer parts.

designed in fusion 360 and printed on a cr10s pro with a duet2 electronics

thingiverse

free

Paper towel holder by peter120

...ent tube diameters. works great.

designed in fusion 360 and printed on a custom linear rail printer with duet electronics.

-peter

thingiverse

free

Bottle cap cone by peter120

...of plastic which takes 12 minutes to print.

designed in fusion 360. custom printer, duet2 electronics with linear rail mechanics.

thingiverse

free

Quill Clamp by peter120

...ed with 0.1mm layer height.

designed in fusion 360 printed on a duet controlled custom printer with linear rails.

have fun

-peter

thingiverse

free

ER40 DA200 DA100 collet tray rack by peter120

... anycubic glass bed with a bit of hair spray.

custom printer: duet controller and linear rail axes.

designed in fusion 360

-peter

thingiverse

free

T8 backlash by peter120

...addition to the weight the x axis.

mounts from the top with the brass nut remaining bolted in place.

works great on my crs10 pro.

Origami

3ddd

free

Origami

... сталь

стул "origami". w 32, d 32, h 40 in.

производитель: www.resourcefurniture.com

3d_ocean

$2

Origami table

...origami table

3docean

furniture origami table

a lowpoly origami table.

turbosquid

$4

ORIGAMI

...id

royalty free 3d model origami for download as max and fbx on turbosquid: 3d models for games, architecture, videos. (1643200)

3ddd

free

Сalligaris Origami

...бариты:

origami big 365х95 мм, высота 330 мм.

origami small 340х91 мм, высота 250 мм.

материалы в сцене настроены для 3х цветов.

3ddd

$1

ванна Stocco Origami

...ванна stocco origami

3ddd

ванна , stocco origami

дизайнерская ванна stocco origami

design_connected

free

Origami Stool

...origami stool

designconnected

free 3d model of origami stool by montina designed by bona, enrico d..

3d_export

$5

origami moth or butterfly

...origami moth or butterfly

3dexport

simple lowpoly origami moth.

turbosquid

$12

Origami-001

...osquid

royalty free 3d model origami-001 for download as max on turbosquid: 3d models for games, architecture, videos. (1685020)

3ddd

$1

PORADA / ORIGAMI

...ием из многослойной фанеры и стеклянной столешницей.

origami

h. 31cm - l. 140cm - p. 140cm

h. 12,20” - l. 55,11” - p. 55,11

3ddd

$1

Origami boconcept, ковер

...origami boconcept, ковер

3ddd

ковер , boconcept

origami boconcept, ковер, ш200xд300см

Bellows

turbosquid

$1

bellows

...oyalty free 3d model bellows for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1656020)

turbosquid

$25

Bellow

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archive3d

free

Bellows 3D Model

...d

forge bellows bellows

bellows n091010 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

Walter Knoll Bellows

...ter knoll , bellows

http://furniteka.com/puf-i-stolik-bellows-ot-walter-knoll/

3d_export

$5

bellows

...sh, material, textures).<br>texture resolution 2048x2048 png:<br>- basecolor, normal, metallic, roughness, occlusion.

turbosquid

$25

bellows-Table

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$25

bellows-chair

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$7

WALTER KNOLL-Bellows

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$16

Bellows side table and stool

...table and stool

designconnected

walter knoll bellows side table and stool computer generated 3d model. designed by nguyen, toan.

turbosquid

$10

Bellows stooltable by Walter Knoll

... model bellows stooltable by walter knoll for download as max on turbosquid: 3d models for games, architecture, videos. (1646694)

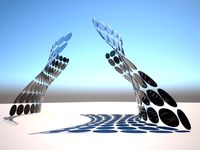

Structure

3ddd

$1

structure

...structure

3ddd

structure

turbosquid

$28

structure

...rbosquid

royalty free 3d model structure for download as max on turbosquid: 3d models for games, architecture, videos. (1338108)

turbosquid

$4

structure

...rbosquid

royalty free 3d model structure for download as max on turbosquid: 3d models for games, architecture, videos. (1338171)

turbosquid

$3

structure

...rbosquid

royalty free 3d model structure for download as fbx on turbosquid: 3d models for games, architecture, videos. (1392940)

turbosquid

free

Structure

...y free 3d model structure for download as 3ds, obj, and blend on turbosquid: 3d models for games, architecture, videos. (1163360)

3d_export

$5

Abandoned structure

...abandoned structure

3dexport

abandoned structure consisting of ground floor and first floor walkable.

3d_export

$5

Small Structure

...all structure

3dexport

small structure static object, formed by a large room and a closet inside, lowpoly model supports the pbr

3ddd

$1

Structure - Kubik

... (в размерах+текстуры+ obj)http://www.lancko.com/structure-collection-kubik-p/lancko-walls-st-ku.htm

archive3d

free

Structure 3D Model

...nstruction structure prefabricated elements

structure - 3d model for interior 3d visualization.

archive3d

free

Structure 3D Model

...chive3d

metal construction structure

structure part-2 - 3d model for interior 3d visualization.

Air

3ddd

$1

Calligaris air

...calligaris air

3ddd

air , calligaris

cтул calligaris air

3ddd

$1

Air freshener

...air freshener

3ddd

air freshener , освежитель

air freshener

design_connected

$16

Air

...air

designconnected

flexform air lounge chairs computer generated 3d model. designed by antonio citterio.

turbosquid

$250

Heat pump air air

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

air

...air

3dexport

3ddd

$1

Кухня AIR

...кухня air

3ddd

air , мария

кухня air фабрики "мария"

3ddd

$1

Лампа AIR

...лампа air

3ddd

boconcept , air

настольная лампа air, boconcept. в50½xø32см

3d_export

$40

air deflector

...air deflector

3dexport

air deflector

3d_export

$15

air purifier

...air purifier

3dexport

air purifier

3d_export

$5

macbook air

...macbook air

3dexport

macbook air