Thingiverse

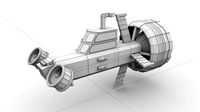

Air assist pressure filter using pop bottle by Klave

by Thingiverse

Last crawled date: 2 years, 10 months ago

So your K40 has a brand new air assist and its supplied from a noisy piston type air pump. The air flow is pulsed and vibrates the lens and makes a noise.

This simple device filters those pulses out to smooth the airflow, if that's what you want. Pulsed air may be better than smooth airflow?

It works by directing the air into a large closed volume, in this case a 2l pop bottle. The pressure pulses go into the bottle where they're absorbed into the large volume. Another port lets the air out at a constant pressure, hardly any pressure variation.

Want some puffing, use a smaller bottle.

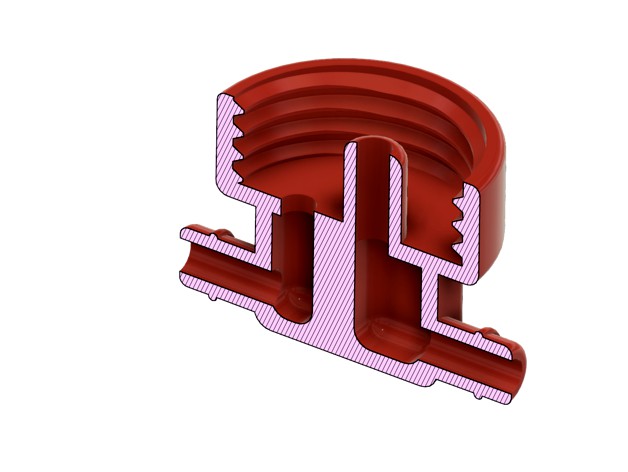

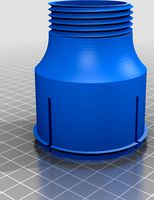

The thing here is simply a bottle top with 2 barbed couplings for the flexible hose between the pump and the laser. There are two versions, the first has slightly longer threads because it has a flat inner surface designed for a cork (or similar) gasket to seal tightly. You don't really need this for your laser because the static pressure is low and a bit of air leaking isn't important.

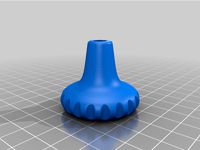

The second version has a small conical sealing ring where the top of the bottle is supposed to seal, it's also not as deep since it doesn't need a gasket. It seals reasonably well but not nearly as well as a proper bottle top. The barbs are more barb-like and the internal spigot also has a small ring to help retain a soft flexible tube.

It could also be used in a different way to filter dirty air, attach a pipe to the inside tube long enough that the end is submerged and it will bubble through the water in the bottle before it goes out the other air port.

Its easy enough to make this device with some hotmelt and a pop bottle to but it will be slightly more tricky to get it to fit because a pop bottle lid is so small. Use a larger mouth bottle if you want to do this, a mason jar for example.

Place this filter near the laser so that the pipe's frictional resistance to airflow helps filter the pulses from the pump, this is basically a first order low pass filter, to those who understand electronics it will make perfect sense.

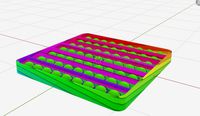

3D printed parts are NOT as air/watertight as you may think, if you want it to be completely air or watertight the you should paint it with nail varnish to seal the porous 3D printed material.

Print with the thread side up, as shown in the picture, and use supports only touching the bed, don't want to fill the internal plumbing with support material!

It leaks air because printed parts are porous

This simple device filters those pulses out to smooth the airflow, if that's what you want. Pulsed air may be better than smooth airflow?

It works by directing the air into a large closed volume, in this case a 2l pop bottle. The pressure pulses go into the bottle where they're absorbed into the large volume. Another port lets the air out at a constant pressure, hardly any pressure variation.

Want some puffing, use a smaller bottle.

The thing here is simply a bottle top with 2 barbed couplings for the flexible hose between the pump and the laser. There are two versions, the first has slightly longer threads because it has a flat inner surface designed for a cork (or similar) gasket to seal tightly. You don't really need this for your laser because the static pressure is low and a bit of air leaking isn't important.

The second version has a small conical sealing ring where the top of the bottle is supposed to seal, it's also not as deep since it doesn't need a gasket. It seals reasonably well but not nearly as well as a proper bottle top. The barbs are more barb-like and the internal spigot also has a small ring to help retain a soft flexible tube.

It could also be used in a different way to filter dirty air, attach a pipe to the inside tube long enough that the end is submerged and it will bubble through the water in the bottle before it goes out the other air port.

Its easy enough to make this device with some hotmelt and a pop bottle to but it will be slightly more tricky to get it to fit because a pop bottle lid is so small. Use a larger mouth bottle if you want to do this, a mason jar for example.

Place this filter near the laser so that the pipe's frictional resistance to airflow helps filter the pulses from the pump, this is basically a first order low pass filter, to those who understand electronics it will make perfect sense.

3D printed parts are NOT as air/watertight as you may think, if you want it to be completely air or watertight the you should paint it with nail varnish to seal the porous 3D printed material.

Print with the thread side up, as shown in the picture, and use supports only touching the bed, don't want to fill the internal plumbing with support material!

It leaks air because printed parts are porous

Similar models

grabcad

free

Pop Bottle Cap

...nd if you need it to be air or watertight it needs to be sealed with something like nail varnish, polyutethane varnish or a paint

thingiverse

free

Bottle Cap Hose Barb 3.0 by Lordofrealms

... the plastic layers because it was so thin. this was true even after some vapor polishing. this one is thicker and does not leak.

thingiverse

free

Soda Bottle to Barb Adapter by Printer_Chuck

...id flexible tubing.

rubber gasket is needed so it does not leak.

be sure the surface for the gasket is smooth to get a good seal.

thingiverse

free

DrinkMate Soda Bottle Adapter by RockSlice

...s may also come into contact with the liquid that you're carbonating, so you may want to apply a food-safe surface treatment.

thingiverse

free

Aquarium Hang-On Waterfall Filter by halimuygun

...gical filtering is working good.

this filter needs a air-pump. and you can paint after printing with spray paint for water leak.

thingiverse

free

Moineau Pump by emmett

... a peristaltic pump because no flexible hose is needed (which tend to reduce efficiency and wear out), plus it doesn't pulse.

thingiverse

free

Tapered barbed fitting to m12 threaded compression by adouglas88

...it.

use a brim or raft when printing if you print at 100 percent infill or it peels off the print bed probably.

tested with petg.

thingiverse

free

Toyota Tacoma Brake Pressure Bleed Adapter by raylo32

...ct fitting on your air lines.

this is not associated with motive products in any way. that is just the bleeder i happen to have.

thingiverse

free

Carepeutic Waterfall Foot and Leg Spa Bath Massager Spout by PixieBandit

...ed ver12: caps the top off so that water would not leak through the dial and created a seal to improve flow on the top waterfall.

thingiverse

free

Pop Bottle 2 Air gun adaptor by Alex9999

...ct a cheap air compressor gun.

uses:

put on pop bottle, shake and spray.

attach bicycle pump to pop bottle and use as air blower.

Klave

thingiverse

free

Dremel Nut by Klave

... scaled 101% in the radial directions to make the fit slightly looser but 100% threaded on fine

lay it on its front face to print

thingiverse

free

LM2596 Enclosure by Klave

...he board. the lid will fit both ways so make sure you check the pot is visible.

for the side entry the lid will only fit one way

thingiverse

free

YAFS Yet another end of of filament sensor by Klave

...x 5.7 mm like these https://www.amazon.ca/gp/product/b07dgx9b9c)

it also doubles as an equally unnecessary filament guide

ender 3

thingiverse

free

Hex bit finger wrench by Klave

...tool holder so i can easily place and remove it. i also put a magnet in the wrench top to stick it to the nearest piece of steel.

thingiverse

free

Filter Sieve by Klave

...s, the bars are an easy distance to bridge, only 3.6mm, and the sides taper at 24 degrees from vertical so no supports are needed

thingiverse

free

CNC Tool Probe by Klave

...e that theirs is normally open and they had to set the probe as active low. this is not needed for my probe which is active high.

thingiverse

free

Honda Civic 2008 Front Emblem by Klave

...ted it, i just made a curved version of the flat one and added the two pins, about 2mm long. you will need supports for this one.

thingiverse

free

K40 mA meter Bezel by Klave

...high voltage on them.

the meter face is 56mm x 64mm and the large round section has a diameter 49mm

mine is similar to this meter

thingiverse

free

Zero Probe by Klave

...rotrude past the print head then you could use it but there are many available options for bed leveling that don't need this.

thingiverse

free

K40 mirrors by Klave

... had this experience, feel free to feed back to the mirror suppliers that their compatibility with k40 is marginal and deceptive.

Pop

design_connected

$18

Pop

...pop

designconnected

kartell pop computer generated 3d model. designed by lissoni, piero.

design_connected

$16

Pop

...pop

designconnected

ligne roset pop chairs computer generated 3d model. designed by christian werner.

3ddd

$1

POP

...d

garsnas , pop

модульный диван. основные размеры: длина - 700, 1400, 2080; ширина - 700

3d_export

$5

pop screw

...pop screw

3dexport

pop screw

3ddd

$1

Pop floral frame

...pop floral frame

3ddd

pop

3 pop floral photo frame

3ddd

$1

Gala Pop Раковина

...gala pop раковина

3ddd

gala , pop

производитель: gala

коллекция: pop

design_connected

$16

Tokyo Pop

...tokyo pop

designconnected

driade tokyo pop computer generated 3d model. designed by yoshioka, tokujin.

3ddd

$1

mantra pop x4

...mantra pop x4

3ddd

mantra , pop

светильник потолочный на 4 рожка. mantra pop x4

design_connected

$18

Tokyo Pop

...tokyo pop

designconnected

driade tokyo pop lounge chairs computer generated 3d model. designed by tokujin yoshioka.

3d_export

free

pop it 3d

...pop it 3d

3dexport

that pop it(antistress toy) in 3d. that pack only suitable for blender. can be used as part of the interior.

Filter

3d_export

$10

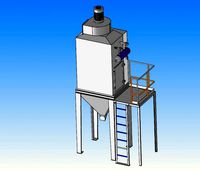

cartridge filter

...cartridge filter

3dexport

cartridge filter

3d_export

$6

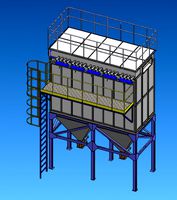

Bag filter

...bag filter

3dexport

bag filter

3d_export

$10

of dust filter

...of dust filter

3dexport

3d model of dust filter

3d_export

$10

of bag filter

...of bag filter

3dexport

3d model of bag filter

3d_export

$7

of bag filter

...of bag filter

3dexport

3d model of bag filter

turbosquid

$20

Filter

...ty free 3d model filter for download as ma, max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1512887)

3d_export

$10

bag filter

...he ash hopper. when the gas containing fine dust passes through the filter material, the dust is retained and the gas is purified

3ddd

$1

UFI Filter

...ufi filter

3ddd

фильтр , ufi

ufi oil filter

turbosquid

$30

Filter

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

filters

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Assist

turbosquid

$120

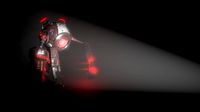

Robot Assistant

...id

royalty free 3d model robot assistant for download as max on turbosquid: 3d models for games, architecture, videos. (1381212)

3d_export

$5

painting assistant

...painting assistant

3dexport

draw samples

3d_export

$5

assistive cane

...assistive cane

3dexport

aristocratic cane for characters

3d_export

$10

Assist bike 3D Model

...assist bike 3d model

3dexport

assist bike

assist bike 3d model modelix 59218 3dexport

turbosquid

$69

computer assistant character

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Robot Assistant

...d

royalty free 3d model 3d robot human for download as blend on turbosquid: 3d models for games, architecture, videos. (1599434)

turbosquid

$30

Galaxy Assistant's Stool

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$15

Prototype version of the robot assistant

...ersion of the robot assistant, designed to help a person in a variety of tasks, both in helping in the garden and in armed escort

turbosquid

$69

Droid Assistant

... robot guard for download as blend, dae, fbx, obj, stl, and x on turbosquid: 3d models for games, architecture, videos. (1624852)

turbosquid

free

Free Realistic Grass Assistant

...3d model free realistic grass assistant for download as blend on turbosquid: 3d models for games, architecture, videos. (1454100)

Pressure

3d_export

$5

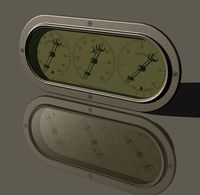

pressure gauge

...pressure gauge

3dexport

pressure gauge

3d_export

$40

Pressure Vessel

...pressure vessel

3dexport

pressure vessel assembly render 3d modelling design

3d_export

$5

Pressure cooker

...pressure cooker

3dexport

simple low-poly pressure cooker model. not removable parts.

3d_export

$5

protected pressure gauge

...protected pressure gauge

3dexport

protected pressure gauge

turbosquid

$25

Vintage US Gauge Co Cluster, Pressure, Oil Pressure & Vacuum Fuel Pressure

...re for download as 3ds, dxf, obj, c4d, fbx, 3dm, dwg, and stl on turbosquid: 3d models for games, architecture, videos. (1367117)

turbosquid

$20

PRESSURIZATION FAN

...

royalty free 3d model pressurization fan for download as max on turbosquid: 3d models for games, architecture, videos. (1269534)

turbosquid

$20

Pressurization Pumps

...oyalty free 3d model pressurization pumps for download as max on turbosquid: 3d models for games, architecture, videos. (1270559)

turbosquid

$23

Pressure cooker

...ee 3d model pressure cooker for download as max, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1440991)

turbosquid

$25

pressure cooker

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$3

Pressure Controller

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Bottle

3d_ocean

$2

Bottle

...bottle

3docean

bottle glass bottle

so realistic glass bottle

archibase_planet

free

Bottle

...bottle

archibase planet

bottle litre bottle glass-ware

bottle - 3d model for interior 3d visualization.

archibase_planet

free

Bottle

...bottle

archibase planet

bottle glass bottle flask

bottle - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

bottles

...bottles

3dexport

bottles

archibase_planet

free

Bottle

...bottle

archibase planet

bottle wine bottle of wine

bottle n121211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bottle

...bottle

archibase planet

bottle bottles kitchen ware

bottle n120213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bottle

...bottle

archibase planet

small bottle bottle vial phial

bottle n060411 - 3d model (*.3ds) for interior 3d visualization.

3d_export

$5

bottle

...bottle

3dexport

bottle with liquid.

archibase_planet

free

Bottle

...bottle

archibase planet

bottle glass

bottle - 3d model for interior 3d visualization.

archibase_planet

free

Bottle

...ibase planet

bottle bottle of port alcohol

bottle of crimean port n090211 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Air

3ddd

$1

Calligaris air

...calligaris air

3ddd

air , calligaris

cтул calligaris air

3ddd

$1

Air freshener

...air freshener

3ddd

air freshener , освежитель

air freshener

design_connected

$16

Air

...air

designconnected

flexform air lounge chairs computer generated 3d model. designed by antonio citterio.

turbosquid

$250

Heat pump air air

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

air

...air

3dexport

3ddd

$1

Кухня AIR

...кухня air

3ddd

air , мария

кухня air фабрики "мария"

3ddd

$1

Лампа AIR

...лампа air

3ddd

boconcept , air

настольная лампа air, boconcept. в50½xø32см

3d_export

$40

air deflector

...air deflector

3dexport

air deflector

3d_export

$15

air purifier

...air purifier

3dexport

air purifier

3d_export

$5

macbook air

...macbook air

3dexport

macbook air

Using

3ddd

$1

US flag

...us flag

3ddd

флаг

us flag

3d_export

free

Among us

...among us

3dexport

among us red

3d_export

free

Among Us

...among us

3dexport

this 3d-model of a character from the game "among us". it can be used as a toy or decoration.

3d_export

$6

among us

...among us

3dexport

doll from among us in red

3d_export

$5

amoung us

...amoung us

3dexport

amoung us character. was created by cinema 4d 19

3d_export

$5

Humvee us

...humvee us

3dexport

humvee us 3d model good quality for animation

3d_export

$15

among us

...among us

3dexport

turbosmooth modifier can be used to increase mesh resolution if necessary

3d_export

$25

mailbox us

...mailbox us

3dexport

low poly model mailbox us. modeling in the blender, texturing in substance painter

design_connected

$13

Use Me

...use me

designconnected

sitland use me computer generated 3d model. designed by paolo scagnellato.

3d_export

$5

Among Us

...rt

the among us model comes in a variety of colors that can be customized by anyone, and even works with little in the animation