Thingiverse

Adjustable Scotty Rod Holder Plate for Track mounts

by Thingiverse

Last crawled date: 4 years, 1 month ago

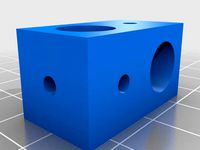

As a person that spends a lot of his fishing time trolling for salmon from a kayak, I was suffering a major first world problem. I love the Scotty mounts and the Orca rod holder - especially with the Scotty Slip Disks - but with only 30 degrees per slot on the rod holder base (12 positions) my rod tip was either too far forward, or too far back. Not only that, but it was slightly different on my Hobie Outback vs. my Hobie Revolution since the track mounts were in different positions. Anyways, I got bored one rainy winter day about 4 years ago and designed a mounting plate that has two 15 degree arced slots at each of the two track mounting points. So, now I can adjust to my hearts content! I tested two prior versions for about two years before coming up with this final version. I have used this final third version hard for two years and I am very happy with it, so I feel it is worth sharing. It should also work for a Ram mount.

I have included a .dxf file which can be cut with a laser or CNC mill and a .pdf file that is to scale if printed on 8.5 x 11 paper and one for A4 that can be used for hand cutting and drilling. The inner circles are sized for #10 stainless steel flat head screws like these https://www.mcmaster.com/machine-screws. The outer circles are the outer boundaries of the 82 degree counter sink needed for the screws. Your length of screw may vary depending on your stock thickness. I have made some 1/4 inch thick and 3/8 inch thick. I prefer the 3/8 since the screw heads are counter sunk, but the one I have used the last two years is only 1/4 inch thick. Tap Plastics has a scrap bin (at least where I am) that has off-cuts of HDPE (Starboard) or you can use an old plastic cutting board.

For those that want to 3D print it, you will have to convert the .dxf. I never made a 3D model since I had no intention of printing it. I had fears of the durability of a 3D printed part holding up to a salmon.

For those into CNC porn, here is a video of how it was cut from a "just big enough" piece of scrap. https://www.youtube.com/watch?v=84kIYEZmf0g

I have included a .dxf file which can be cut with a laser or CNC mill and a .pdf file that is to scale if printed on 8.5 x 11 paper and one for A4 that can be used for hand cutting and drilling. The inner circles are sized for #10 stainless steel flat head screws like these https://www.mcmaster.com/machine-screws. The outer circles are the outer boundaries of the 82 degree counter sink needed for the screws. Your length of screw may vary depending on your stock thickness. I have made some 1/4 inch thick and 3/8 inch thick. I prefer the 3/8 since the screw heads are counter sunk, but the one I have used the last two years is only 1/4 inch thick. Tap Plastics has a scrap bin (at least where I am) that has off-cuts of HDPE (Starboard) or you can use an old plastic cutting board.

For those that want to 3D print it, you will have to convert the .dxf. I never made a 3D model since I had no intention of printing it. I had fears of the durability of a 3D printed part holding up to a salmon.

For those into CNC porn, here is a video of how it was cut from a "just big enough" piece of scrap. https://www.youtube.com/watch?v=84kIYEZmf0g

Similar models

thingiverse

free

FIshing Rod Balancer by jeffrm20

...mounts. i have incuded mounts for attwood and scotty rod holders and adapter that will fit right into the hobie sail mast pocket.

thingiverse

free

Scotty Gopro mount by zzalrs

...ign to create a gopro mount that attaches to a scotty rod holder extension for my kayak.https://www.thingiverse.com/thing:3838711

thingiverse

free

Shower Curtain Rod Holder by SomePerson7979

...it can't be knocked out of the holder. has two screw slots that are slightly recessed at the top for screw heads to go in to.

thingiverse

free

Scotty Flush Mount Base by jeffrm20

...scotty flush mount base by jeffrm20

thingiverse

flush mount base for the scotty rod holders etc.

thingiverse

free

Base mount for scotty rod holders by Deifox

...base mount for scotty rod holders by deifox

thingiverse

rod holder base/dock.

thingiverse

free

Toothbrush Holder by ECaseyP

...th pla on an ender 3 v2. so far the brush holder is holding up to daily use by my family, our two year old finds it fascinating.

thingiverse

free

Scotty Cup Holder by jeffrm20

...ave to fit them together, or one piece but might need a lot of supports. please let me know what i can do to improve this design.

thingiverse

free

Fishing Rod Holder by tapndie

...rod holder by tapndie

thingiverse

fishing rod holder can either be screwed or mounted with 3m vhb tape. fits 1 inch rod handles.

thingiverse

free

GoPro rod holder mount by nytowl

...d mount.

i intend to use it with my radio mount to keep my radio in sight while paddling

http://www.thingiverse.com/thing:1703604

thingiverse

free

Rod double block by uwezi

... diameter aluminum rods. on my winhao di3 a hole with 3 mm inner diameter in pla is self-tapping with standard, metric m3 screws.

Scotty

turbosquid

$7

Devon & Devon - SCOTTIE

...devon & devon - scottie for download as c4d, max, and fbx on turbosquid: 3d models for games, architecture, videos. (1590468)

turbosquid

$12

TOS Original Series Scotty 39s Magnatomic Scope

... magnatomic scope for download as max, obj, fbx, dwg, and stl on turbosquid: 3d models for games, architecture, videos. (1488602)

free3d

free

Scotty

...scotty

free3d

scotty character

thingiverse

free

scotty mount by budof76

...scotty mount by budof76

thingiverse

scotty mount 90 deg

thingiverse

free

Scotty backplate by akhenatn

...scotty backplate by akhenatn

thingiverse

scotty mount backplate for kayak install

thingiverse

free

scotty mount base by uwes

...scotty mount base by uwes

thingiverse

connects to two scotty footers and has a scotty compatible mount (female)

thingiverse

free

Scotty Mount Extension by jessefarlow

...scotty mount extension by jessefarlow

thingiverse

scotty mount extension.

thingiverse

free

Scotty Railblaza Adapter by Doenne90

...scotty railblaza adapter by doenne90

thingiverse

scotty railblaza adapter

thingiverse

free

Scottie Dog Cufflink by ccombema

...scottie dog cufflink by ccombema thingiverse scotty dog shaped...

thingiverse

free

scotty mount connector by uwes

...scotty mount connector by uwes

thingiverse

simple connector for two scotty mount bases

Track

design_connected

$11

Tracks

...tracks

designconnected

bonaldo tracks computer generated 3d model. designed by gilles, alain.

3d_export

$30

TRACK

...track

3dexport

turbosquid

$20

tracks

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Tracks

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Track

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$2

Track

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$65

track

...track

3dexport

simple rendering of the scene file

3d_export

$65

track

...track

3dexport

simple rendering of the scene file

3d_export

$65

track

...track

3dexport

simple rendering of the scene file

3ddd

free

Стол Bonaldo Tracks

...onaldo , tracks , обеденный

стол bonaldo tracks

Rod

archibase_planet

free

Rod

...rod

archibase planet

shank rod

so rod - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Spinning rod

...g rod

archibase planet

spinning rod spinning rod fishing-rod

spinning rod - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

rod handle

...rod handle

3dexport

rod handle

3ddd

$1

bench with rods

...bench with rods

3ddd

скамейка

bench with rods

3ddd

$1

диван ROD

...диван rod

3ddd

rod , living divani

http://www.livingdivani.it/

3ddd

$1

кресло ROD

...кресло rod

3ddd

rod , living divani

http://www.livingdivani.it/

design_connected

$18

Rod Armchair

...rod armchair

designconnected

living divani rod armchair computer generated 3d model. designed by lissoni, piero.

archive3d

free

Rod 3D Model

...rod 3d model

archive3d

shank rod

so rod - 3d model (*.gsm+*.3ds) for interior 3d visualization.

turbosquid

$15

Fishing rod

...urbosquid

royalty free 3d model fishing rod for download as on turbosquid: 3d models for games, architecture, videos. (1684756)

archive3d

free

Spinning rod 3D Model

...d spinning rod fishing-rod

spinning rod - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Plate

archibase_planet

free

Plates

...plates

archibase planet

plates and dishes plate

plates - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

plate

...plate

3dexport

plate

archibase_planet

free

Plates

...plates

archibase planet

plates and dishes plate kitchen ware

plates - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Plates

...plates

archibase planet

plate plates and dishes crockery

plates 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Plate

...plate

archibase planet

dinner-plate plate kitchen ware

plate n070808 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$6

plate

...plate

3dexport

design of plate

3d_export

$5

plate

...plate

3dexport

plate lowpoly

archibase_planet

free

Plates

...plates

archibase planet

plate dish kitchen-ware

plate - 3d model for interior 3d visualization.

3ddd

$1

Plates

...plates

3ddd

полка , тарелка

african plates

archibase_planet

free

Plate

...plate

archibase planet

plate kitchen ware

plate - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Adjustable

3d_ocean

$7

Adjustable Wrench

...adjustable wrench

3docean

adjustable wrench highly detailed wrench

highly detailed adjustable wrench.

3ddd

$1

Adjustable Stool

...adjustable stool

3ddd

табурет

wooden adjustable stool.

3d_ocean

$20

Adjustable Gym Bench

...st adjustable bench black equipement gym gymnastic indoor silver sport workout

3d model of black and silver adjustable gym bench.

3d_ocean

$20

Adjustable Gym Bench

...st adjustable bench black equipement gym gymnastic indoor silver sport workout

3d model of black and silver adjustable gym bench.

3d_ocean

$16

Adjustable Weight Bench

...arbell bench black equipement gym gymnastic indoor sport weight workout

3d model of black adjustable weight bench with a barbell.

turbosquid

$5

Adjustable wrench

...

royalty free 3d model adjustable wrench for download as fbx on turbosquid: 3d models for games, architecture, videos. (1313414)

3d_export

$5

adjustable tension lock

...adjustable tension lock

3dexport

adjustable tension lock

turbosquid

$1

Adjustable Wrench

...free 3d model adjustable wrench for download as obj and blend on turbosquid: 3d models for games, architecture, videos. (1446736)

turbosquid

$1

Adjustable Wrench

...y free 3d model adjustable wrench for download as c4d and fbx on turbosquid: 3d models for games, architecture, videos. (1379022)

3d_export

$5

Adjustable key

...adjustable key

3dexport

Holder

archibase_planet

free

Holder

...holder

archibase planet

holder toilet paper holder

holder paper n070712 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...e planet

holder rack toilet paper holder

holder toilet roll n240715 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pen holder support prop

pen holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

pole post holder

сhurch cross pole holder - 3d model for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder bathroom ware

shower holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...oilet paper holder

holder paper devon&devon; time black n241113 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 7 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder hanger hanger for towel

holder 3 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...holder

archibase planet

holder towel rack towel-horse

holder - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Holder

...lder

archibase planet

holder hanger hanger for towel

holder towel n250912 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

Mounts

3d_export

free

mounting bracket

...the part of a hinge, handle or latch that mounts the hardware to a cabinet. mounting plates make it...

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$39

Mount rainier

...quid

royalty free 3d model mount rainier for download as fbx on turbosquid: 3d models for games, architecture, videos. (1492586)

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

turbosquid

$3

Mounting Tires

...uid

royalty free 3d model mounting tires for download as fbx on turbosquid: 3d models for games, architecture, videos. (1708511)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)