GrabCAD

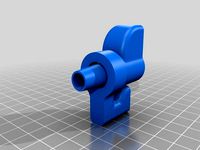

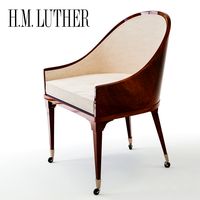

Ultem(R)ate Bracket B2 (0.023 lbs, 0.481 cu in)

by GrabCAD

Last crawled date: 1 year, 10 months ago

Ultra lightweight bracket, one-piece design of only 0.023 lbs and a volume of 0.481 cubic inches. Further development of my Ultem(R)ate Bracket B1.

Using common 3D printing features to reduce mass of unstressed but thick parts (bosses).

Stresses all less than 4500 psi, singularity/stress riser in FE model (due to contact between bolt and bracket) calculated analytically to find correct contact pressure and Hertzian stresses. No optimisation needed: Preliminary sizing done using basic mechanical theory, verified using FEM.

The bracket can be printed without supporting structures. The elastic hinge allows for aligning the two halves during mounting on the launch vehicle. There's ample room foor tools to reach (NAS1104) bolts. Mass is reduced even further by using a 15% infill density in unstressed areas.

Extra loadcase: differential pressure of 14.7 psi on inside of infill volume to avoid breakup of bracket during ascent.

Please find all details on the calculations and read about the design considerations in the pdf file attached.

To illustrate the differences in stress distributions I've added a picture (of one of my other entries in the challenge, but the difference is the same in all entries) that shows stresses in a bracket with real contact between the bracket and bolt on the left, and bonded contact between the bolt an bracket on the right.

Kind regards,

Wilbert Engels

Using common 3D printing features to reduce mass of unstressed but thick parts (bosses).

Stresses all less than 4500 psi, singularity/stress riser in FE model (due to contact between bolt and bracket) calculated analytically to find correct contact pressure and Hertzian stresses. No optimisation needed: Preliminary sizing done using basic mechanical theory, verified using FEM.

The bracket can be printed without supporting structures. The elastic hinge allows for aligning the two halves during mounting on the launch vehicle. There's ample room foor tools to reach (NAS1104) bolts. Mass is reduced even further by using a 15% infill density in unstressed areas.

Extra loadcase: differential pressure of 14.7 psi on inside of infill volume to avoid breakup of bracket during ascent.

Please find all details on the calculations and read about the design considerations in the pdf file attached.

To illustrate the differences in stress distributions I've added a picture (of one of my other entries in the challenge, but the difference is the same in all entries) that shows stresses in a bracket with real contact between the bracket and bolt on the left, and bonded contact between the bolt an bracket on the right.

Kind regards,

Wilbert Engels

Similar models

grabcad

free

Ultem(R)ate Bracket C2 (0.021 lbs, 0.440 cu in)

...en the bracket and bolt on the left, and bonded contact between the bolt an bracket on the right.

kind regards,

wilbert engels

grabcad

free

Ultem(R)ate Bracket B1 (0.028 lbs, 0.578 cu in)

... bolt on the left, and bonded contact between the bolt an bracket on the right.

kind regards,

wilbert engels (october 18, 2016)

grabcad

free

Ultem(R)ate Bracket C1 (0.018 lbs, 0.376 cu in)

...nd bolt, left, and a fixed bore hole ("bonded contact between bracket and bolt) on the right.

kind regards,

wilbert engels

grabcad

free

bracket simple

...i with f.o.s about 4

second moment of inertia = .5^4 inch

volume 91.09 cubic inches

max. shear stress 600 psi

mass .05 lb

grabcad

free

Yellowasp

...yellowasp

grabcad

material: ultem 9085

volume: 27518.8 mm3

mass: 0.081 lb

fos: 1.5

displacement: 0.012 in

stress: 3048 psi

grabcad

free

Atlas V - reduced mass support bracket

...to my first model. material is removed from several places.

this bracket is optimized for 3d printing without support material.

grabcad

free

Bracket

....040 inches

bone - as one of the lightest and strongest material in the world, was my inspiration during proceeding this project.

grabcad

free

ULA bracket 44.4G

...951 in^3

density: 0.0368498 lb/in^3

weight: 0.0979361 lbf

a file with details of load calculations is available in the downloads.

grabcad

free

ULA bracket 44.2G

...004 in^3

density: 0.0368498 lb/in^3

weight: 0.0975873 lbf

a file with details of load calculations is available in the downloads.

grabcad

free

ULA bracket 45.2G

...936 in^3

density: 0.0368498 lb/in^3

weight: 0.0997717 lbf

a file with details of load calculations is available in the downloads.

Ultem

thingiverse

free

JGAurora A5 E3D V6 conversion – 30 mm fans by MacheadSk

...printing service and asked them to print it from ultem 1010 (or pei). this is a high grade, high...

thingiverse

free

Shock mount for Aston Origin by The-explorer

...long as its soft. i printed my parts in ultem 9085, but any material will...

thingiverse

free

RZR fire extinguisher mount _kiddie bottle by Gnarkill1332

...abs pla or low heat filaments, for nylon and ultem you only need the set with the release bar...

thingiverse

free

Wall-mounted soap tray dish replacement

...them over the years. be sure to print with ultem or perhaps petg (or something with a high temperature),...

thingiverse

free

Sap Tap (Maple Syrup) by mussy

...approved) ceramics pla without additives pet, petg / t-glass ultem 9085 polypropylene natural grade nylon 6 & 6.6 (without...

thingiverse

free

Boosted Board V2 Skid Plates by xGETxALECx

...for printing. i only recommend nylon,nylon x, nylon g, ultem peek or sls using a nylon 12. any thing...

thingiverse

free

Sauce & Dip (Kitchen) by mussy

...approved) ceramics pla without additives pet, petg / t-glass ultem 9085 polypropylene natural grade nylon 6 & 6.6 (without...

thingiverse

free

Wake RTA Venturi Drip Tip (11mm internal Dia.) by GadsdenGuy

...(ce221), which is a highly temperature resistant material. (think ultem those insanely priced 30$ tips). i would also recommend...

thingiverse

free

Dual shot glass by Rihards_Klauzs

...approved): ceramics pla without additives pet, petg / t-glass ultem 9085 polypropylene natural grade nylon 6 & 6.6 (without...

thingiverse

free

late 80s Evinrude 40hp 2stroke outboard T fuel line cuppling thing by DavidDow

...the spare part market, and cost 40€(!!) print in ultem or any material and use nanoseal or something to...

481

3ddd

$1

Фотоаппарат "Zenit 11"

...«гелиос-44м-4», «мс гелиос-44м-4». всего фотоаппаратов «зенит-11» было выпущено 1 481 022...

3d_ocean

$5

Pillar_1

...low pillar old stone pillar post pylon 2048*2048 texture. 481 polygon low poly. obj,fbx,and blend...

3d_ocean

$17

Superman - MP and HP Textured Model

...geometry : polygons. poly count (triangles): mp : 11 481 hp : 184 680 files : .obj (multi...

3ddd

free

Z 481 Sigma L2

...z 481 sigma l2

3ddd

sigma l2

z 481 sigma l2

3ddd

$1

VALELUNGA - PIETRE DEI CONSOLI

...consoli 3ddd итальянская фабрика. плитка нескольких типоразмеров: 321*321 и 481481 мм. в архиве два цвета - ноче и беж,...

cg_studio

$100

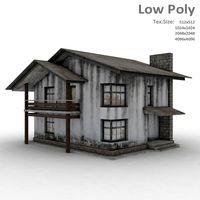

3d building 4813d model

... building 4813d model

cgstudio

.max - 3d building 481 3d model, royalty free license available, instant download after purchase.

3ddd

free

Комод Boori Country

...ящика + дополнительные полки размеры: ширина: 872 мм глубина: 481 мм высота: 1796...

3ddd

$1

Devon&Devon BERKELEY

..., berkeley polys - 244 550 vertex - 123 481 ...

3ddd

free

Boori Country Sleigh

...комод , boori country размеры: д 912 x ш 481 x в 894 присутствуют все 5 вариантов цвета, предлагаемых...

3ddd

$1

Зеркало к комоду «Бристоль»

...прозрачная отделка. размеры (шхвхг): 962х900х98 цвет: темное ссылка на мебель:http://www.miassmebel-magazin.ru/catalog/18/481amp;nbsp; ...

023

3d_export

$155

Building 023 3D Model

...terior resort hotel bank office center university college campus street landscape

building 023 3d model rosestudio 53717 3dexport

cg_studio

$50

Guest Room 0233d model

...us grand deluxe premium interior

.max - guest room 023 3d model, royalty free license available, instant download after purchase.

3ddd

free

Система купе

..., металл , шкаф купе сисиема раздвижный дверей yeniler mk-023 производитель турция. модель полностью идентична...

3d_ocean

$12

Garden Furniture 023

...r separate models) .max (3ds max 2010 for the scene, whose models are presented as xref objects with proxy object option) .max...

3d_ocean

$9

Gazebo 023

...2010 for separate models .max (3ds max 2010 for the scene, whose models are presented as xref objects with proxy object option...

3d_ocean

$4

Window 023

...2010 for separate models .max (3ds max 2010 for the scene, whose models are presented as xref objects with proxy object option...

3d_ocean

$4

Pedestal 023

...x 2010 for separate models) .max (3ds max 2010 for the scene, whose models are presented as xref objects with proxy object opt...

3d_ocean

$14

Bridge 023

...2010 for separate models .max (3ds max 2010 for the scene, whose models are presented as xref objects with proxy object option...

3d_ocean

$5

Column 023

...2010 for separate models) .max (3ds max 2010 for the scene, whose models are presented as xref objects with proxy object optio...

3d_ocean

$19

Building 023

...••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• it comes in a range of formats that will easily can be...

Ate

3ddd

$1

CARACOLE Night Cap

...uot;night cap" ats-kinbed-002

80w x 89.75d x 52h

nightstands - "best in glass" ats-nitstd-004

25.5w x 17d x 26h

3ddd

$1

Architects Chair by Caracole

... ats-chair-04b

architects chair by caracole

ats-chair-04b

686d x 686w x 813h mm

polys: 159 126

verts: 159 448

3ddd

$1

CARACOLE Comfort Zone

...one" ats-kinbed-001

81.5w x 87.75d x 54h

nightstands - "artisans nightstand"

ats-nitstd-001

33w x 18d x 29.25hl

3d_ocean

$89

Cadillac ATS 2013

...model was created on real car base. it’s created accuratey, in real units of measurement, qualitatively and maximally close...

cg_studio

$99

Cadillac ATS-V Coupe 20163d model

...x .lwo .fbx .c4d .3ds .obj - cadillac ats-v coupe 2016 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

Cadillac ATS 20133d model

...

.3ds .c4d .fbx .lwo .max .mb .obj - cadillac ats 2013 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

Cadillac ATS Coupe 20153d model

...3ds .c4d .fbx .lwo .max .obj - cadillac ats coupe 2015 3d model, royalty free license available, instant download after purchase.

cg_studio

$99

Cadillac ATS 20133d model

...dio

.3ds .c4d .fbx .lwo .max .obj - cadillac ats 2013 3d model, royalty free license available, instant download after purchase.

3ddd

$1

Trizo 21 \ Cri-Ate

...zo 21 \ cri-ate

3ddd

trizo21

модификации можно посмотреть в pdf каталоге на сайте производителяhttp://www.trizo21.com/.

cg_studio

$99

Cadillac ATS-V Sedan 20163d model

...j .max .lwo .fbx .c4d .3ds - cadillac ats-v sedan 2016 3d model, royalty free license available, instant download after purchase.

B2

3ddd

$1

Branca Lisboa R&B2

...anca

"лаунж" кресло от португальцев branca lisboa.

массив ясеня, натуральный, либо крашенный в белый или черный цвета.

3ddd

$1

Кресло Kare

...kare кресло,дерево, ппу, лен,740/530/490 product number: 79294 взято с сайта:https://www.kare-design.com/shop/ru-moscow/ru/%d0%9a%d1%80%d0%b5%d1%81%d0%bb%d0%be-%d0%b4%d0%b5%d1%80%d0%b5%d0%b2d0%be-%d0%9f%d0%9f%d0%a3-%d0%bb%d0%b5%d0%bd-740-530-490/79294 в архиве присутствует модель в...

3ddd

$1

Кровать AMOS

...кровать amos 3ddd amos http://www.archiproducts.com/ru/%d0%bf%d1%80%d0%be%d0%b4%d1%83%d0%ba%d1%82%d1%8b/21490/%d0%ba%d1%80%d0%be%d0%b2d0%b0%d1%82%d1%8c-amos-nube-italia.html ...

3ddd

$1

Чайный столик

...чайный столик 3ddd журнальный чайный столик 800х600х260 изготоление этнической мебелиhttps://www.facebook.com/pages/%d0%9c%d0%b0%d1%81%d1%82%d0%b5%d1%80%d1%81%d0%ba%d0%b0%d1%8f-%d0%a8%d0%b5%d1%80%d0%b2d1%83%d0%b4/1547143605519211?pnref=story ...

3ddd

$1

Раковина Laufen

...раковина laufen 3ddd laufen , ilbagnoalessi one , умывальник http://www.laufen.ru/ru/products/product-finder/%d1%80%d0%b0%d0%ba%d0%be%d0%b2d0%b8%d0%bd%d1%8b/813971 умывальник...

3ddd

$1

Подвесной светильник OISEAU

...sign to accompany us in all rooms of a house.http://www.archiproducts.com/ru/%d0%bf%d1%80%d0%be%d0%b4%d1%83%d0%ba%d1%82%d1%8b/120373/%d0%bf%d0%be%d0%b4%d0%b2d0%b5%d1%81%d0%bd%d0%be%d0%b8-%d1%81%d0%b2%d0%b5%d1%82%d0%b8%d0%bb%d1%8c%d0%bd%d0%b8%d0%ba-oiseau-compagnie.html ...

3ddd

$1

BoConcept Fargo

...boconcept fargo 3ddd boconcept , fargo сайт производителя и описание:http://www.boconcept.com/ru-ru/furniture/living/sofas/fargo/5946/%d0%b4%d0%b8%d0%b2d0%b0%d0%bd-fargo размеры: в84xш250xг99cm. polys: 215115 verts:...

3ddd

$1

BONALDO Nuvola

...viganò , bonaldo , nuvola ссылка на сайт производителя :http://www.bonaldo.it/it/prodotti/divani/nuvola/giuseppe-vigan%c3%b2amp;nbsp; ...

3ddd

$1

Диффузор B2-200

...вующих размеров

тел. +7 495 979-26-89, 8 800 100-54-25

время работы с 9-00 до 19-00 пн-пт, с 10-00 до 17-00 сб, вск - выходной.

3ddd

$1

Диван BoConcept Monaco

...boconcept , monaco диван monaco с модулем для отдыха ссылкаhttp://www.boconcept.com/ru-ru/furniture/living/sofas/monaco/23868/%d0%b4%d0%b8%d0%b2d0%b0%d0%bd-monaco-%d1%81-%d0%bc%d0%be%d0%b4%d1%83%d0%bb%d0%b5%d0%bc-%d0%b4%d0%bb%d1%8f-%d0%be%d1%82%d0%b4%d1%8b%d1%85%d0%b0 ...

Cu

3ddd

$1

Hooker Furniture Living Room Wakefield Drop Leaf Table

...45 1/2" height 31" weight 141.1 lb volume 18.43 cu ft carton width 28 carton height 16.25 carton weight...

3d_ocean

$6

Meko The Monkey

...with simple geometry, allowing for the user to fully cu.. ...

3d_ocean

$15

Low Poly Micro Ghost Hubert

...to take the game one step further with his cu.. ...

3d_ocean

$18

Photoreal Eames Chair - DAR + vray materials

...comes with the plastic shell version, with and without cu... ...

3ddd

$1

Шкаф из массива тика Lucy

...из массива тика lucy 3ddd lucy , d-bodhi артикул cudbh-lc-620101 бренд d-bodhi ширина 50 см глубина 45 см высота...

3d_export

$10

primum work desk-suite p l cu armchair

... yes<br>box trick: yes<br>model parts: 6<br>render: v-ray, corona<br>formats: 3ds max 2013, obj, fbx, 3ds

3d_export

$10

suite ap l cu lounge armchair

...yes<br>box trick: yes<br>model parts: 14<br>render: v-ray, corona<br>formats: 3ds max 2013, obj, fbx, 3ds

3d_export

$10

apelle dp cu armchair

... yes<br>box trick: yes<br>model parts: 8<br>render: v-ray, corona<br>formats: 3ds max 2013, obj, fbx, 3ds

3d_export

$10

suite p l cu armchair

... yes<br>box trick: yes<br>model parts: 3<br>render: v-ray, corona<br>formats: 3ds max 2013, obj, fbx, 3ds

3d_export

$5

lgkitchenappliances

...instaview® electric slide-in range with air fry https://www.lg.com/us/cooking-appliances/lg-lsel6335d-electric-range 1.8 cu ft. over-the-range microwave oven with easyclean® https://www.lg.com/us/cooking-appliances/lg-lmv1831bd-over-the-range-microwave 36'' wall...

Lbs

design_connected

$18

Knitting Armchair

...knitting armchair

designconnected

menu knitting armchair computer generated 3d model. designed by kofod-larsen, lb.

3ddd

$1

RH VICTORIAN HOTEL FLOOR LAMP + DESK LAMP

...dimensions overall: 18" diam., 72"h cord: 78"l weight: 108.5 lbs p.s люстры из этой коллекции смотрите в моих...

3ddd

$1

SONATA steel CF-LB chrome

...onata steel cf-lb chrome

3ddd

стул , новый стиль

новый стиль - sonata steel cf-lb chrome

3ddd

$1

NADIR extra CF LB

...nadir extra cf lb

3ddd

новый стиль

новый стиль - nadir extra cf lb

3ddd

$1

зеркало Donghia + постеры Eichholtz

... 60.5" (154 cm)

width: 42" (107 cm)

weight: 136 lb (62 kg)

intro year: 2001

постеры eichholtz в зеркальных багетах!

3ddd

$1

Светильники "DESIGN Stockholm HOUSE"

...cm (6"), h 35 cm (14"), 4 kg (9 lbs; measurements small: ø 15 cm (6"), h 22 cm...

3ddd

$1

RAPSODY extra CF LB

...rapsody extra cf lb

3ddd

новый стиль

новый стиль - rapsody extra cf lb

3ddd

$1

Star Steel chrome CFA LB

...lb

3ddd

новый стиль , стул

новый стиль - кресло для посетителей star steel chrome cfa lb

3ddd

$1

подвес Kichler Lighting 2666ACO

...watts light bulb socket type: medium base incandescent light bulbs included: no wiring type: hardwire chain length: 36...

3ddd

$1

Ledoux Sconce

...5.5 d n e t w t . 5 lbs bac k p l at e / j-box 4.5”...

R

3d_export

$99

Vauxhall Agila 2008 3D Model

...vauxhall agila 2008 3d model 3dexpor vauxhall agila 2008 2009 2010 europe suzuki wagon r+...

3d_export

$99

Volkswagen Golf VII R 5door 2015 3D Model

...or volkswagen vw detailed interior golf vii 2017 hothatch 5door 5d

volkswagen golf vii r 5door 2015 3d model squir 90150 3dexport

3d_export

$129

Scania R1000 2014 AeroTrailer 3D Model

...mi transport scania r1000 r-1000 hevy wheeler trailer tir aerotrailer

scania r1000 2014 aerotrailer 3d model squir 73046 3dexport

3d_export

$15

Wheel Detroit Cobra R rims and tire 3D Model

...ormance disk brake caliper brembo yokohama detroit cobra

wheel detroit cobra r rims and tire 3d model 3dlogicline 54693 3dexport

3ddd

$1

мойка накладная "Imperial" 6080-R

...мойка накладная "imperial" 6080-r

3ddd

мойка

мойка накладная "imperial", размер 800*600, арт. 6080-r

3ddd

$1

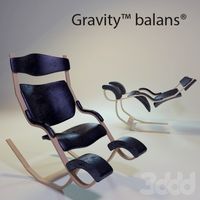

Gravity balans

...зводитель: varier

модель: gravity balans

дизайнер: peter opsvikhttp://www.varier.ru/collections/relax/gravity-balans-r/

3ddd

$1

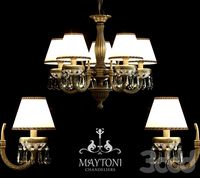

Maytoni СL1028-05-R

...dd

maytoni

люстра maytoni сl1028-05-r

(коллекция classic)

высота: 360

диаметр: 520

цвет: брасс

ламп: 5 x e14 (60w)

www.maytoni.ru

3d_ocean

$29

Scania Truck

...poly machine scania scania r scania r420 swedish car tractor truck trailer vehicle

high poly truck with vray lighting and camera.

3d_ocean

$49

English Family House

...the objects are modeled using real world dimensions. the r.. ...

3d_ocean

$85

Vauxhall Combo Tour H1L1 2015

...of measurment. all car parts are correctly named. model is created in autodesc maya 2012, visualization (rendering) – mental r...

Bracket

3d_export

$20

BRACKETS LIGHTS 3D Model

...ets lights 3d model

3dexport

night lamp home interioer bulb tube matel glass

brackets lights 3d model kunjanvirani 25181 3dexport

3ddd

$1

Nix

...sheet metal tops and the hollow section of the bracket. the highest version also has a wooden or leather...

3ddd

$1

Swedish Neoclassical Mahogany Armchair

...interior, on four square tapering legs headed by arched bracket, ending in brass sabots with wood...

3ddd

$1

Уличный фонарь “Palacio”

..., night , landscape , iaf , pole , bracket , lights , outdoor , park , square ,...

archive3d

free

Sconce 3D Model

...sconce 3d model archive3d sconce lamp-bracket lantern sconce - 3d model (*.gsm+*.3ds) for interior 3d...

archive3d

free

Sconce 3D Model

...sconce 3d model archive3d sconce lamp-bracket lantern sconce - 3d model (*.gsm+*.3ds) for interior 3d...

archive3d

free

Sconce 3D Model

...sconce 3d model archive3d lamp-bracket sconce lighting sconce n180408 - 3d model (*.gsm+*.3ds) for...

archive3d

free

Sconce 3D Model

...sconce 3d model archive3d sconce lantern lamp-bracket sconce n030412 - 3d model (*.gsm+*.3ds) for interior 3d...

archive3d

free

Sconce 3D Model

...sconce 3d model archive3d sconce lantern lamp-bracket sconce n050412 - 3d model (*.gsm+*.3ds) for interior 3d...

archive3d

free

Sconce 3D Model

...sconce 3d model archive3d sconce lantern lamp-bracket sconce 4 n280312 - 3d model (*.gsm+*.3ds) for interior...

0

3ddd

$1

HEMSMAK collection

...503.235.78 303.130.14 403.150.55 703.150.49 903.150.34 203.150.37 003.150.57 403.150.41 903.150.48 80.115.12 регулируемый...

3ddd

$1

Of Interni OF.17/6/FR

...особенность дизайна - полностью закрывающая модель "вуаль" из текстильной бахромы.http://www.360ru/goods/0/0/0/84658/ ...

3ddd

$1

Silvano Grifoni

...silvano grifoni 3ddd silvano grifoni , круглый http://www.360ru/goods/3/461/0/89288/ ...

3d_ocean

$15

Highpoly 3d Model of Electrostatic Machine

...animated: no uv mapped: no unwrapped uvs: yes cameras: 0 lights: 0...

3d_ocean

$9

GLOWING AND RIGGED ALPHABET A TO Z

...a to z and numeric letter from 1 to 0 all rigged and glowing like light and its rigged...

3d_export

$7

Lion pand 0 3D Model

... model

3dexport

lion pand

lion pand 0 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl gorgsalvatore 113339 3dexport

3ddd

$1

Новогоднее оформление камина

...старинного камина. внимание! на объектах turbosmooth iterations снижен до 0 в файле .obj сглаживание включено. больше видов можно посмотреть...

3ddd

$1

OF.C05T, Of Interni

... каркасе из металла. гофрированный абажур украшен длинными хрустальными подвесками.http://www.360.ru/goods/0/0/0/84756/

3ddd

$1

Of Interni

...of interni 3ddd of interni люстра в классическом стиле.италия.http://www.360ru/goods/0/0/0/84785/ ...

3ddd

$1

DAIQUIRI EURONORM

...для проветриваемом охлаждения с испарительной антикоррозионной краской для температуры 0 +8 ° c или -18-20 ° c , статическая...