Thingiverse

Prusa MK3S MMU2S purge bucket _NEW version by Forfelet

by Thingiverse

Last crawled date: 3 years, 3 months ago

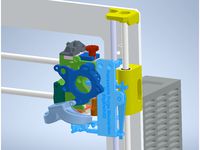

It's a remix from my original design.

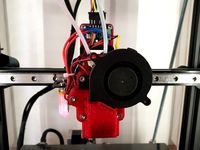

I redesigned the holder to match with my new X axis (https://www.thingiverse.com/thing:3670659)

Now, this purge bucket can be installed on all X axis versions (stock, Bear, ...)

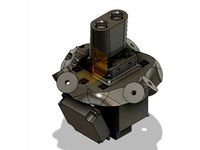

Z-axis top right should be replace for that. STL is available (directly remixed from Prusa website).

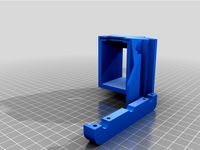

To print correctly (PETG 0.2mm 20% grid), please print these parts according to the last picture. Don't print the Holder lying flat.

Holder : supports everywhere

Spacer: supports from build plate only

Trigger: no supports

Bucket: supports from build plate only

Materials needed:

1 screw M3x20 for trigger, but you can use the trigger without screw with stock extruder (not tested on others)

1 screw M3x4

1 rubber band or a spring 20.6x5.1. I advise you the spring.

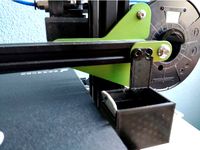

Please follow this instruction list: (also available in Files with pictures)

HARDWARE PART :

Add screw on the trigger (according to the trigger used)

Add rubber band (or spring) between holder and spacer

Add screw on the spacer to hold the bucket (need adjustment after the installation)

Remove Z-axis top right

Remove rod 8mm

Install holder with spacer and trigger

Put the rod 8mm (be careful with bearing)

Replace Z-axis top right by the new part

Check rotation if it's free. It's NOK, check that all supports on holder are removed. (I know, it's not easy...)

Adjust position of the bucket and the screw on the trigger

Perform a Calibration Z.

It's finished for the Hardware part!

SOFTWARE PART:

In PrusaSlicer,

go to "Print Settings" and uncheck "Wipe tower"

go to "Printer Settings" and copy/paste this script in the tool change section:

; toolchange from [current_extruder] to [next_extruder], layer [layer_num]

{if current_extruder != next_extruder}

;before tool change

M106 S0 ;turn off fan

G92 E0 ;turn off retraction

G1 E-0.8 F2100 ;retract

G1 Y100 F12000 ;break filament before lifting

G1 X200 F12000 ;move head to position

; G91;change in relative position

{if layer_z < 25.0}

G1 Z26; z-lift if lower than 25 mm

{endif}

G90;transition to absolute position

G4 S0 ;clean up buffer movement

G1 X240 F12000 ;move head to purge area

G1 X250 F2000

G1 X254 F1000 ;extend the buscket

;end of pre-tool change gcode

; Start cleaning the filament before extraction

M220 B ; turn aux v1.0.5

M220 S100 ; change of loading tool

;(Replace tip shaping section if doing Vintagepc tip shaping)

;*Begin PLA Tip shaping*****

G1 E0.7644 F3639

G1 E0.8248 F3926

G1 E0.8483 F8483

G1 E-15.000 F6000

G1 E-24.500 F1200

G1 E-7.000 F600

G1 E-3.500 F360

{if layer_num < 1}

M104 S[first_layertemperature[nextextruder]] ; toolchange set the extruder temperature - first layer

{else}

M104 S[temperature[next_extruder]] ; toolchange set the extruder temperature - other layers

{endif}

G1 E20.000 F488

G1 E-20.000 F326

G1 E-35.000 F2000

G4 S0

;*End PLA Tip shaping*****

;---------------;

T[next_extruder] ;tool change

;start the purge after changing the tool

M107 ;turn off fan

G92 E0 ;reset the position of the extrusion

G1 E12 F400 ;filament support

G1 E50 F700 ;acceleration for nozzle loading

G1 E43 F150;nozzle purge,3

G1 E6 F180;nozzle purge E66 F200

G1 E11 F200;nozzle purge

G1 E10 F250;nozzle purge

G1 E10 F280;nozzle purge

G1 E3.0000 F300

G1 E3.0000 F350; retract 20mm at a speed of 110

M106 S255 ;turn on fan

G4 S2 ;cool the filament

G92 E0 ;reset the position of the extrusion

{if layer_num > 0}

G1 E-[retract_lengthtoolchange[next_extruder]] F1500 ;retract to avoid seepage

{else}

; no retraction on first toolchange

{endif}

{if layer_z > .25}

M106 S51

{endif}

G1 X240 F5000 ;bucket go back home

G1 X200 F12000 ;bucket go back home

M220 R ; restore speed

;end of tool purge gcode

{else}

; no extruder change

{endif}

It's finished for the Software part and this installation !

Slice and test !

I redesigned the holder to match with my new X axis (https://www.thingiverse.com/thing:3670659)

Now, this purge bucket can be installed on all X axis versions (stock, Bear, ...)

Z-axis top right should be replace for that. STL is available (directly remixed from Prusa website).

To print correctly (PETG 0.2mm 20% grid), please print these parts according to the last picture. Don't print the Holder lying flat.

Holder : supports everywhere

Spacer: supports from build plate only

Trigger: no supports

Bucket: supports from build plate only

Materials needed:

1 screw M3x20 for trigger, but you can use the trigger without screw with stock extruder (not tested on others)

1 screw M3x4

1 rubber band or a spring 20.6x5.1. I advise you the spring.

Please follow this instruction list: (also available in Files with pictures)

HARDWARE PART :

Add screw on the trigger (according to the trigger used)

Add rubber band (or spring) between holder and spacer

Add screw on the spacer to hold the bucket (need adjustment after the installation)

Remove Z-axis top right

Remove rod 8mm

Install holder with spacer and trigger

Put the rod 8mm (be careful with bearing)

Replace Z-axis top right by the new part

Check rotation if it's free. It's NOK, check that all supports on holder are removed. (I know, it's not easy...)

Adjust position of the bucket and the screw on the trigger

Perform a Calibration Z.

It's finished for the Hardware part!

SOFTWARE PART:

In PrusaSlicer,

go to "Print Settings" and uncheck "Wipe tower"

go to "Printer Settings" and copy/paste this script in the tool change section:

; toolchange from [current_extruder] to [next_extruder], layer [layer_num]

{if current_extruder != next_extruder}

;before tool change

M106 S0 ;turn off fan

G92 E0 ;turn off retraction

G1 E-0.8 F2100 ;retract

G1 Y100 F12000 ;break filament before lifting

G1 X200 F12000 ;move head to position

; G91;change in relative position

{if layer_z < 25.0}

G1 Z26; z-lift if lower than 25 mm

{endif}

G90;transition to absolute position

G4 S0 ;clean up buffer movement

G1 X240 F12000 ;move head to purge area

G1 X250 F2000

G1 X254 F1000 ;extend the buscket

;end of pre-tool change gcode

; Start cleaning the filament before extraction

M220 B ; turn aux v1.0.5

M220 S100 ; change of loading tool

;(Replace tip shaping section if doing Vintagepc tip shaping)

;*Begin PLA Tip shaping*****

G1 E0.7644 F3639

G1 E0.8248 F3926

G1 E0.8483 F8483

G1 E-15.000 F6000

G1 E-24.500 F1200

G1 E-7.000 F600

G1 E-3.500 F360

{if layer_num < 1}

M104 S[first_layertemperature[nextextruder]] ; toolchange set the extruder temperature - first layer

{else}

M104 S[temperature[next_extruder]] ; toolchange set the extruder temperature - other layers

{endif}

G1 E20.000 F488

G1 E-20.000 F326

G1 E-35.000 F2000

G4 S0

;*End PLA Tip shaping*****

;---------------;

T[next_extruder] ;tool change

;start the purge after changing the tool

M107 ;turn off fan

G92 E0 ;reset the position of the extrusion

G1 E12 F400 ;filament support

G1 E50 F700 ;acceleration for nozzle loading

G1 E43 F150;nozzle purge,3

G1 E6 F180;nozzle purge E66 F200

G1 E11 F200;nozzle purge

G1 E10 F250;nozzle purge

G1 E10 F280;nozzle purge

G1 E3.0000 F300

G1 E3.0000 F350; retract 20mm at a speed of 110

M106 S255 ;turn on fan

G4 S2 ;cool the filament

G92 E0 ;reset the position of the extrusion

{if layer_num > 0}

G1 E-[retract_lengthtoolchange[next_extruder]] F1500 ;retract to avoid seepage

{else}

; no retraction on first toolchange

{endif}

{if layer_z > .25}

M106 S51

{endif}

G1 X240 F5000 ;bucket go back home

G1 X200 F12000 ;bucket go back home

M220 R ; restore speed

;end of tool purge gcode

{else}

; no extruder change

{endif}

It's finished for the Software part and this installation !

Slice and test !

Similar models

thingiverse

free

A20M A10M BigMac MKII 5015 Blower

...

g1 e70 f3000

g92 e0

g1 e30 f200

g92 e0

g4 s3

g0 f10000

; end extruder 2

g92 e0

g1 e-5 f6000

g1 x-10.5 f8000

g1 e-70 f3000

g92 e0

thingiverse

free

SVO2 Purge Bucket and GCODE by RedSquirrelHobbies

... positioning on

g1 z-1 f1000 ; lower nozzle by 1mm

g90 ; absolute positioning on

m400 ; wait for finish

thingiverse

free

Geeetech A10t Purge Bucket with removable bucket by 123TaDa

...ipe

g0 x0 f2000 ; return

m211 s1 ; turn on soft stops once more

g1 e-0.5 ; try to prevent pips

g92 e0

; start extruder script end

thingiverse

free

A10M A20M Purge extension (Aibecy hotend) by deakbannok

...91 ; switch from absolute positioning to relative positioning

g1 z-0.4 f800 ;

g90 ; return to absolute

g1 e6.5 f3600.0 ;

g92 e0 ;

thingiverse

free

Purge Bucket for A10M (cleaned up) by carterlewellyn

... e0 ;reset extruder positioning

g1 e-2 f5000 ;retract filament to resting spot

g92 e0 ;reset extruder positioning

i hope it helps

thingiverse

free

Kossel Magnetic Effector by Debio

... 8mm, my retraction speed is 40mm/sec, my toolchange retraction distance is 90mm, and my toolchange retraction speed is 50mm/sec.

thingiverse

free

nozzle cleaning bin by Calo_pc

...

g1 e125 f3000 ;extrude the new selected filament to the nozzle

g92 e0;

g1 e4 f180;

g92 e0;

//g1 e-3 f3600 ; retract the filament

thingiverse

free

E3D v6 dual extrusion by dunno_k

...g

g1 e-150.000 f12000 ; reatrac fully fast to rip of eventual strings

t[new_tool]

g92 e0

g1 e151.000 f900 ; prime extruder

g92 e0

thingiverse

free

Bukito Purge box

...ing code for use with purge box

g28 ;home

g1 z.1 f6000 ;move the platform down .1mm

;prime the extruder

g92 e0

g1 f200 e10

g92 e0

thingiverse

free

Filament mixer / dual extrusion / mixing extruder by techwit

...ge to snap off

g92 e0

---snip---

my setup is a e3d lite using a pair of these extruders http://www.thingiverse.com/thing:1708020

Forfelet

thingiverse

free

Purge - Mount Right remixed by Forfelet

...purge - mount right remixed by forfelet

thingiverse

i added 2 nuts (m3) to extend the lifetime of this part.

thingiverse

free

Splitter for MMU2S 5 paths by Forfelet

...nd ptfe od4mm id3mm

2 versions available,

both versions are ok.

if your filament tips are not perfect, please use the version v2.

thingiverse

free

MMU2-front PTFE Holder PC4-M10 by Forfelet

...://www.thingiverse.com/thing:4680412

designed for pc4-m10, now it's possible to remove entirely the selector from mmu2s unit.

thingiverse

free

Prusa Mk3S MMU2S Tower Print Buffer without spools holder by Forfelet

...ools holder by forfelet

thingiverse

this buffer is excellent, but i don't need the spools holder. so, i modify the fixation.

Mmu2S

thingiverse

free

MMU2S Adapter Printer

...mmu2s adapter printer

thingiverse

proper piece to upgrade an mk3 mmu2 to an mk3s mmu2s

thingiverse

free

mmu2s extension by mumg

...mmu2s extension by mumg

thingiverse

added support of endstop for mmu2 idler

thingiverse

free

MMU2 Buffer horizontal stand

...mmu2 buffer horizontal stand

thingiverse

the mmu2 stand is designed for the ikea lack housing and two stacked samla dryboxes.

thingiverse

free

MMU2S M10 Passthrough Selector

...assthrough selector

thingiverse

designed for a better path from mmu2s selector to printer with m10 passthrough bowden connector.

thingiverse

free

Spiral tree MMU2

...spiral tree mmu2

thingiverse

not suitable for printing in vase mode

thingiverse

free

Prusa MMU2 Light Bar

...prusa mmu2 light bar

thingiverse

simple remix of mr_tantrum's prusa mk3/mk3s light bar in order to accommodate for the mmu2

thingiverse

free

Prusa MMU2 tube holder for filament

...prusa mmu2 tube holder for filament

thingiverse

wall tubes 6pcs holder between filament and mmu2 unit

thingiverse

free

Sonicare Toothbrush Holder for MMU2/S

...e toothbrush holder for mmu2/s

thingiverse

added color rings on the top of the toothbrush stands, to print it with prusa mmu2/s.

thingiverse

free

MMU2s Quick Test by MrPUSH

...thingiverse

i made this mmu2s quick test because i wanted something that would switch colors quickly. i usually add a 10mm brim.

thingiverse

free

Idles MMU2 Beermat

...d this at 95mm x 95mm x 2mm with 100% infill.

for more beermats, see my group:

https://www.thingiverse.com/groups/beermats/things

Purge

3d_export

$20

yoda

...of the few jedi to survive the great jedi purge<br>features:<br>high quality polygon model - correctly scaled accurate representation of...

3dfindit

free

IAQ-PURGE

...iaq-purge

3dfind.it

catalog: nuaire

thingiverse

free

Purge Bucket by Gavster29

...purge bucket by gavster29

thingiverse

replacement purge bucket, to use with cheap brushes from amazon

thingiverse

free

Nereus Purge Bucket

...nereus purge bucket

thingiverse

it's all in the name: this is a purge bucket for dual extrusion adapted to tevo nereus.

thingiverse

free

Bac pour Purge A20M

...bac pour purge a20m

thingiverse

bac pour purge a20m

thingiverse

free

Purge Calibration Cube

...urge calibration cube

thingiverse

just a simple cube to calibrate how much material you need to purge in between filament swaps.

thingiverse

free

Skelestruder -> Retractable Purge Mechanism

... of these 3 parts:

purge - mount_right.stl

purge - bracket.stl

purge - action.stl

then assemble as standard.

thanks! =dbigbrain3d

thingiverse

free

Purge Pan by bsbmx

...nce inside the 'bowl', but its purpose is just to collect purged and wasted plastic, so it doesn't need to be pretty.

thingiverse

free

Purge Bucket Anet by horus2678

...purge bucket anet by horus2678

thingiverse

allow to purge anet printer in a bucket instead drawing lines

thingiverse

free

Mosquito hotend -> RETRACTABLE PURGE MECHANISM

... of these 3 parts:

purge - mount_right.stl

purge - bracket.stl

purge - action.stl

then assemble as standard.

thanks! =dbigbrain3d

Mk3S

turbosquid

$129

MK3 Tank

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$100

Toyota Supra MK3

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$30

Challenger I Mk3 Falcon

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

American Frag hand grenade MK3

...free 3d model american frag hand grenade mk3 for download as on turbosquid: 3d models for games, architecture, videos. (1393624)

turbosquid

$20

Mk3 US Navy Combat Knife

...ty free 3d model mk3 us navy combat knife for download as fbx on turbosquid: 3d models for games, architecture, videos. (1172791)

3d_export

$29

Ford Fiesta MK3 Modified 3D Model

...7 tumerfx mtumer mehmet t?mer 1993 1995 1996 wrc special modifed modifiye

ford fiesta mk3 modified 3d model mtumer 30698 3dexport

3d_export

$99

Toyota Supra Mk3 19861993 3D Model

...ort fast coupe japan 1986 1987 1988 1989 1990 1991 1992 1993 tuning turbo

toyota supra mk3 19861993 3d model squir 62530 3dexport

turbosquid

$5

Timothy Oulton Mars Chair MK3

...on mars chair mk3 for download as 3ds, max, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1209782)

3d_export

$150

Handley page halifax MK3 RAF 3D Model

...mk3 bomber british ww2 war second world royal air force raf airplane

handley page halifax mk3 raf 3d model tartino 87044 3dexport

turbosquid

$2

Frame Filament Guide Clip-On for Prusa Mk3

...rame filament guide clip-on for prusa mk3 for download as stl on turbosquid: 3d models for games, architecture, videos. (1634730)

Bucket

archibase_planet

free

Bucket

...bucket

archibase planet

pail bucket tub

bucket - 3d model for interior 3d visualization.

3d_ocean

$5

Bucket

...bucket

3docean

bucket cleaning galvanized gavanised stainless steel zinc zinc coated

a galvanized bucket

turbosquid

free

Bucket bucket With Water

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

archibase_planet

free

Bucket

...bucket

archibase planet

bucket pail

bucket n250308 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bucket

...bucket

archibase planet

tub bucket pail

bucket - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bucket

...bucket

archibase planet

bucket pail bin

bucket n280612 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bucket

...bucket

archibase planet

pail bucket tub

bucket 2 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Bucket

...bucket

archibase planet

fire fighting equipment dip-bucket

bucket - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3d_export

$5

bucket

...bucket

3dexport

scratched galvanized bucket. fbx, obj, blend, and testura formats

3ddd

$1

Wooden bucket

...wooden bucket

3ddd

wooden bucket , ведро

wooden bucket

Prusa

turbosquid

$2

Frame Filament Guide Clip-On for Prusa Mk3

...rame filament guide clip-on for prusa mk3 for download as stl on turbosquid: 3d models for games, architecture, videos. (1634730)

3d_export

free

prusa i3 mk3s laser mount for opt lasers

...to learn more about the blue laser technology that conceived the cutting and engraving laser heads from opt lasers, please visit:

turbosquid

free

Prusa small printer adapter holder

...er for download as ipt, skp, dwg, dxf, fbx, ige, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1642936)

3d_export

$30

geisha by jonathan adler

...** i did a 3d printing test in the prusa software, you can find it among the attached images.<br>exchange:<br>.blend...

thingiverse

free

Prusa without Prusa (rc2) by madless

...prusa without prusa (rc2) by madless

thingiverse

just the main part of prusa rc2 faceshield, without writing.

enjoy :)

thingiverse

free

Prusa by acejbc

...prusa by acejbc

thingiverse

prusa knob info

m3 8mm screw

thingiverse

free

Prusa house

...prusa house

thingiverse

how prusa house could look like...

thingiverse

free

Prusa Mk2 "Fake Prusa" LCD cover by anraf1001

...r by anraf1001

thingiverse

version of prusa's lcd cover with "fake prusa" instead of "original prusa"

thingiverse

free

Prusa stabilizator by gutiueugen

...prusa stabilizator by gutiueugen

thingiverse

prusa stabilizator

thingiverse

free

Keychain Prusa by rbarbalho

...keychain prusa by rbarbalho

thingiverse

keychain with text prusa.

New

turbosquid

$119

New New Beetle

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

New-feather

...new-feather

3dexport

new-feather

3d_export

$6

new style

...new style

3dexport

new style room

3ddd

free

New Items

...ew items

3ddd

new items , барный

барный стул от китайского производителя фирмы new items

3d_export

$6

Logo new

...logo new

3dexport

new american style logo

3d_export

$10

New jersey

...new jersey

3dexport

new jersey stp and stl format

design_connected

$20

New Deal

...new deal

designconnected

new deal computer generated 3d model.

3d_ocean

$15

New bed

... for this bed all this file format include in zip file 3ds,obj,max,zip file change material and re-size very easy very for render

3ddd

free

Sofa-New Classic

...sofa-new classic

3ddd

new classic

sofa,new classic

design_connected

$13

New Antiques

...new antiques

designconnected

cappellini new antiques computer generated 3d model. designed by wanders, marcel.

Version

3ddd

$1

Diamond version

...nd , version , ванна

visionnaire - diamond bath

turbosquid

$50

LibraryMini Version

...free 3d model librarymini version for download as max and jpg on turbosquid: 3d models for games, architecture, videos. (1617724)

design_connected

$34

Barocco Version 01

...barocco version 01

designconnected

zanotta barocco version 01 computer generated 3d model. designed by progetti, emaf.

design_connected

$27

Barocco Version 02

...barocco version 02

designconnected

zanotta barocco version 02 computer generated 3d model. designed by progetti, emaf.

turbosquid

free

![Door [2 versions]](/t/13243146.jpg)

Door [2 versions]

...rbosquid

free 3d model door [2 versions] for download as fbx on turbosquid: 3d models for games, architecture, videos. (1223985)

turbosquid

$2

seat version 0.1

...

royalty free 3d model seat version 0.1 for download as blend on turbosquid: 3d models for games, architecture, videos. (1432653)

3d_export

$10

magnolia grandiflora mature version

...magnolia grandiflora mature version

3dexport

magnolia grandiflora mature version

3d_export

$8

room assets and voxel version

...room assets and voxel version

3dexport

room assets and voxel version

turbosquid

$35

Zil Civilian version

... model zil civilian version for download as cgf, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1639420)

turbosquid

$3

Chair 3 versions

...3d model chair 3 versions for download as blend, fbx, and obj on turbosquid: 3d models for games, architecture, videos. (1657530)