Thingiverse

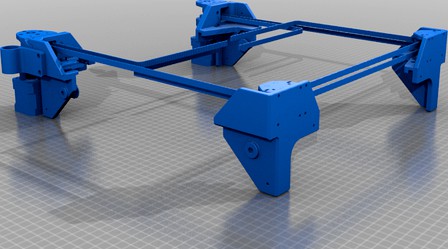

Gudo Xy Core - By Charles Guy Doppia & Neotko

by Thingiverse

Last crawled date: 4 years, 2 months ago

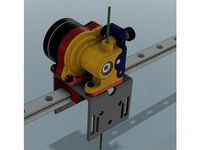

First of all, this MOD uses ZGE as extruder but has parts that have been rebuild for this big mod that changes UMO/UMO+/UM2 gantry to CoreXY

It uses Bondtech as drivergears, Duet3D as mainboard and, to print I use TheOlssonRuby nozzles, just because for me they are the freaking best.

https://www.thingiverse.com/thing:2348263

All is ZIPPED for your maker enjoyment on one file, with step files, stl, etc.

General

Gudo and I made this, specially him but I pushed him over a year to reuse the umo/um2 frame into a CoreXY machine, since we both had many issues on UM2 gantry style to print fast, without vibrations and as fast as possible since we modded the machine into ZGE (small added weight on DD clearly shows how weak the XY gantry um2 style printers are and how limited the max speeds become)

So this mod is unfinished, but also finished, Gudo did pass away in the summer of 2018 and it took me quite some time to get strength and post all. Not just because work, but because it was a really sad thing to do, to post this without him.

But Gudo always wanted to share, create, improve and make better machines than what we have. This is an advanced mod, it requieres you to open step files, check stuff, and thing. You will need to align the parts so they print right, file MANY parts, to adjust them, insert tons of screws, get boxes of short/medium/long screws and check again and again where all goes. Thing of if as the most complex (and in the end you will see isn't that hard at all) diy-rebuild-printer.

How much stays and how much it goes from a UM2?

You keep the bed, hotend, frame, stepper motors and some pulleys and bearings. The controller board goes away, the belts, lots of smooth rods, all that goes away (except one that can be reused for the X, but I never did that, nilrog ( https://twitter.com/nilrog ) on twitter has that version from Gudo for his UM2GO-gudoXycore version. Will upload his zip for added mod fun if you are into this.

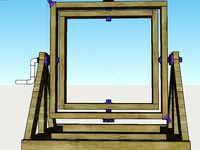

All the gantry installation is made by hand, I did design very easy corner guides for umo+ frame that help to make drills, they are very easy to make, just get the Step file with all assembled Gudo made, and do some booleans of the holes and make a printable guide, check mine for reference of what I mean. This will help you drill the holes for the hiwin/misumi rails.

To align the rails you just need to semi screw two top-bottom rails, not tight, and then adjust the distance relative to each side panel, use a fixed distance and align the rail, when is straight tight one, adjust the length and tight the other. If you did drill this correctly (remember to leave gap for screw movement so you can align all) the rest comes easily.

After setting both Y rails, when the X rails comes in, you can align the X using the panel as helper and the hotend. Push in front, check its perfectly align and tight the Y rail holders to the rains, side by side, slow and with patience.

Charles Guy Doppia, Gudo for me, made a Xy Core info that someone published onhttps://www.gecko3dprinter.com/2-assembly/5-xy-belts/

Mind that this is for the 3D Gecko, the machine we did toy with for quite sometime. Gudo tips will give you a bit of insight about what's important to keep an eye on the gudoXyCore.

More questions!??

For help and questions DONT PM me, please use public twitter post so keep info and answers public to everyonehttps://twitter.com/neotko/status/1215257844368453632

Video references that can be useful

Wiring and 5V fan cable on Duet3D 2.xhttps://www.youtube.com/watch?v=VNkVqTN0v_Y

How to change pins order on molex cables (if you need to switch motor directions can be usefull)https://www.youtube.com/watch?v=aXLPB5e71Ng

Small mod to plug PT100 cables on the Duet3D not exactly needed the 'solder' part, but usefull anyhowhttps://www.youtube.com/watch?v=GJCLiqsz_ho

How to CRIMP cables - Check minute 7+https://www.youtube.com/watch?v=tRU7LPtAVGw

FILES

Check the 'NEOTKO EXTRAS' folder

I made a Y rail holder that uses 1cm Square Aluminium bar as reinforcement, it does work great on 3 machines, but you will need to make a lot of drills and manual labour. If you want it easy, buy 2 rails for X, ofc it's more money, but....

Also check the CONFIG.G text file, it will help you setup the Duet3D faster, but not automagic, you need to read before using it.

BOM

Option A) Hiwin rails MGN9H for X x1 254mm / and 2x 275mm qty 3 ( or 275 and you cut them the wanted length)

Option B) MISUMI RAILS for Y x2 SELBV10-275-MC for X x1 SELBV10-254-MC

Note if you use MISUMI for the Y you need to adjust the front corners since their heigh is smaller, easy to boolean before printing

Bearings

F604ZZ 4x12x4 qty 18

625ZZ 5x16x5 qty 4 -

6800ZZ 10x19x5 qty 2 <- FOR zge motor holder

Motor Flex coupler

5mm x 5mm qty 2

Geared Bondtech motor qty 1

GT2 belt

You need at least 3m of GT2 6mm belts get good quality ones

Reusing UM GT2 20T pulleys

5mm motor pulley qty 2 (XY motor)

8mm pulley qty 1 (Z geared motor)

5mmx40mm motor pulley shaft qty 2 ( hobby car driving shaft could be used )

4mmx30mm Xrail bearing shaft qty 2 ( M4 x30mm set screws could be used)

Fasteners

M3 bolts and nuts :

6mm chc qty 8 (Yrail slider bloc)

8mm countersunk head qty 4 (Xrail slider bloc)

8mm chc qty 10

10mm chc qty 10

12mm chc qty 30

16mm chc qty 30

18mm chc qty 10

25mm chc qty 10

30mm chc qty 20

35mm chc qty 20

45mm chc qty 2 (XY pivot motor holder)

hex M3 nuts qty 100

square nuts qty 100

M4 bolts

30mm qty 10

35mm qty 10

square M4 nuts qty 10

IMPORTANT NOTE ABOUT BOM

Some screw numbers are APROX, Gudo never did the final BOM, but it's accurate. You might end having a few extras

Thanks to

Thanks to Duet3D for making a modern printer controler that can be adjusted easy and FAST without firmware rebuilding or boring stuff. Thanks to Bondtech for making such a highquality drivegears (just my oppinion, they never sent even a discount) and SPECIAL thanks to The Olsson Ruby, just just an amazing nozzle, but also Eric, Anders Olsson and all that cool guys that keep pushing the boundaries.

Also, special thanks to Foehnsturm. I did put Gudo and Him in contact years ago and they talked about how to improve and make the XY motors belt tensioning system, one of the key parts for this CoreXY to work as nciely as it does. If you don't know Foehnsturm, he's the guy that came with the Mark2 Tool changer and one of the most brilliant guys I know.

It uses Bondtech as drivergears, Duet3D as mainboard and, to print I use TheOlssonRuby nozzles, just because for me they are the freaking best.

https://www.thingiverse.com/thing:2348263

All is ZIPPED for your maker enjoyment on one file, with step files, stl, etc.

General

Gudo and I made this, specially him but I pushed him over a year to reuse the umo/um2 frame into a CoreXY machine, since we both had many issues on UM2 gantry style to print fast, without vibrations and as fast as possible since we modded the machine into ZGE (small added weight on DD clearly shows how weak the XY gantry um2 style printers are and how limited the max speeds become)

So this mod is unfinished, but also finished, Gudo did pass away in the summer of 2018 and it took me quite some time to get strength and post all. Not just because work, but because it was a really sad thing to do, to post this without him.

But Gudo always wanted to share, create, improve and make better machines than what we have. This is an advanced mod, it requieres you to open step files, check stuff, and thing. You will need to align the parts so they print right, file MANY parts, to adjust them, insert tons of screws, get boxes of short/medium/long screws and check again and again where all goes. Thing of if as the most complex (and in the end you will see isn't that hard at all) diy-rebuild-printer.

How much stays and how much it goes from a UM2?

You keep the bed, hotend, frame, stepper motors and some pulleys and bearings. The controller board goes away, the belts, lots of smooth rods, all that goes away (except one that can be reused for the X, but I never did that, nilrog ( https://twitter.com/nilrog ) on twitter has that version from Gudo for his UM2GO-gudoXycore version. Will upload his zip for added mod fun if you are into this.

All the gantry installation is made by hand, I did design very easy corner guides for umo+ frame that help to make drills, they are very easy to make, just get the Step file with all assembled Gudo made, and do some booleans of the holes and make a printable guide, check mine for reference of what I mean. This will help you drill the holes for the hiwin/misumi rails.

To align the rails you just need to semi screw two top-bottom rails, not tight, and then adjust the distance relative to each side panel, use a fixed distance and align the rail, when is straight tight one, adjust the length and tight the other. If you did drill this correctly (remember to leave gap for screw movement so you can align all) the rest comes easily.

After setting both Y rails, when the X rails comes in, you can align the X using the panel as helper and the hotend. Push in front, check its perfectly align and tight the Y rail holders to the rains, side by side, slow and with patience.

Charles Guy Doppia, Gudo for me, made a Xy Core info that someone published onhttps://www.gecko3dprinter.com/2-assembly/5-xy-belts/

Mind that this is for the 3D Gecko, the machine we did toy with for quite sometime. Gudo tips will give you a bit of insight about what's important to keep an eye on the gudoXyCore.

More questions!??

For help and questions DONT PM me, please use public twitter post so keep info and answers public to everyonehttps://twitter.com/neotko/status/1215257844368453632

Video references that can be useful

Wiring and 5V fan cable on Duet3D 2.xhttps://www.youtube.com/watch?v=VNkVqTN0v_Y

How to change pins order on molex cables (if you need to switch motor directions can be usefull)https://www.youtube.com/watch?v=aXLPB5e71Ng

Small mod to plug PT100 cables on the Duet3D not exactly needed the 'solder' part, but usefull anyhowhttps://www.youtube.com/watch?v=GJCLiqsz_ho

How to CRIMP cables - Check minute 7+https://www.youtube.com/watch?v=tRU7LPtAVGw

FILES

Check the 'NEOTKO EXTRAS' folder

I made a Y rail holder that uses 1cm Square Aluminium bar as reinforcement, it does work great on 3 machines, but you will need to make a lot of drills and manual labour. If you want it easy, buy 2 rails for X, ofc it's more money, but....

Also check the CONFIG.G text file, it will help you setup the Duet3D faster, but not automagic, you need to read before using it.

BOM

Option A) Hiwin rails MGN9H for X x1 254mm / and 2x 275mm qty 3 ( or 275 and you cut them the wanted length)

Option B) MISUMI RAILS for Y x2 SELBV10-275-MC for X x1 SELBV10-254-MC

Note if you use MISUMI for the Y you need to adjust the front corners since their heigh is smaller, easy to boolean before printing

Bearings

F604ZZ 4x12x4 qty 18

625ZZ 5x16x5 qty 4 -

6800ZZ 10x19x5 qty 2 <- FOR zge motor holder

Motor Flex coupler

5mm x 5mm qty 2

Geared Bondtech motor qty 1

GT2 belt

You need at least 3m of GT2 6mm belts get good quality ones

Reusing UM GT2 20T pulleys

5mm motor pulley qty 2 (XY motor)

8mm pulley qty 1 (Z geared motor)

5mmx40mm motor pulley shaft qty 2 ( hobby car driving shaft could be used )

4mmx30mm Xrail bearing shaft qty 2 ( M4 x30mm set screws could be used)

Fasteners

M3 bolts and nuts :

6mm chc qty 8 (Yrail slider bloc)

8mm countersunk head qty 4 (Xrail slider bloc)

8mm chc qty 10

10mm chc qty 10

12mm chc qty 30

16mm chc qty 30

18mm chc qty 10

25mm chc qty 10

30mm chc qty 20

35mm chc qty 20

45mm chc qty 2 (XY pivot motor holder)

hex M3 nuts qty 100

square nuts qty 100

M4 bolts

30mm qty 10

35mm qty 10

square M4 nuts qty 10

IMPORTANT NOTE ABOUT BOM

Some screw numbers are APROX, Gudo never did the final BOM, but it's accurate. You might end having a few extras

Thanks to

Thanks to Duet3D for making a modern printer controler that can be adjusted easy and FAST without firmware rebuilding or boring stuff. Thanks to Bondtech for making such a highquality drivegears (just my oppinion, they never sent even a discount) and SPECIAL thanks to The Olsson Ruby, just just an amazing nozzle, but also Eric, Anders Olsson and all that cool guys that keep pushing the boundaries.

Also, special thanks to Foehnsturm. I did put Gudo and Him in contact years ago and they talked about how to improve and make the XY motors belt tensioning system, one of the key parts for this CoreXY to work as nciely as it does. If you don't know Foehnsturm, he's the guy that came with the Mark2 Tool changer and one of the most brilliant guys I know.

Similar models

thingiverse

free

Customizable nema 17 stepper motor spacer by MoonCactus

...rint them in pla!).

the default spacing is 15mm but you can change it with the customizer, along with all other useful variables.

thingiverse

free

Beyond UMO & UM2 Slideblocks by Gudo & Neotko - GT2 Open Belt by Neotko

...ideblock. you can a) glue it, b) fuse with heat a bit the plastics so it never moves or c) print very slow and use the tight fit.

thingiverse

free

X-Axis Idler Pulley Alignment Clip for Monoprice Select Mini by USWaterRockets

...: https://hackaday.io/project/14823-monoprice-select-mini-maximum-3d-printer-mods/log/52155-keeping-the-x-axis-belt-from-twisting

grabcad

free

V-Belt Idler Pulley

...ad

v-belt idler pulley. in this pulley, we use following parts:

1) v-belt pulley

2) ball bearing

3) bushing qty. -2

4) snap ring

thingiverse

free

Mark 2 for UM2 and UM3 Cores by Gudo (Charles Guy Doppia)

...will need to print slow, or deburring edges and assemble with love, just like gudo made it, to be build with care and perfection.

thingiverse

free

Rotational Casting Machine (RotoCast) by Miaviator

... 3/4" schedule 40 pvc pipe

2 pvc elbows

staple gun (i stapled the gt2 belt to join it)

assembly should be self explanatory.

thingiverse

free

Sapphire Plus Experimental Mount by nimeq

...don't know how to rotate it to print it, it's probably not ready for your use. it needs to be mirrored to the other side.

grabcad

free

ZCarriageAssambly

...45

2 linear rails ø8x400

1 nema 17 motor support(50mm)

1 nema 17 motor

1 belt drive(gt2)

1 belt pulley(gt2)

1 belt pulley support

thingiverse

free

Ender 5 linear rail mod Y axis

...20mm travel (you have to put a bigger glass bed on)

if you like my design feel free to tip my designhttps://www.paypal.me/djdenzo

thingiverse

free

axis alignment tool for the Ultimaker S5 by UltiArjan

...ltiple tools are available already)

as the s5 has a 10mm x axis and a 8mm y axis you need 2 sets of tools, so print both tools 2x

Gudo

thingiverse

free

Mark 2 for UM2 and UM3 Cores by Gudo (Charles Guy Doppia)

...will need to print slow, or deburring edges and assemble with love, just like gudo made it, to be build with care and perfection.

thingiverse

free

Titan E3D - East3DGecko 35x35x10 Delta Blowers Fancap by Neotko

...sure it stays there forever. a design based on gudo fan design. it's a beta so expect errors, but...

thingiverse

free

Beyond UMO & UM2 Slideblocks by Gudo & Neotko - GT2 Open Belt by Neotko

...ideblock. you can a) glue it, b) fuse with heat a bit the plastics so it never moves or c) print very slow and use the tight fit.

thingiverse

free

UMO / UM2 - Experimental Vibration dampening foots by Neotko

...doing jobs with different heights. thanks to iroberti and gudo for the input and ideas to make this...

thingiverse

free

Zero Gravity Extruder Direct Drive by Gudo & Neotko by Neotko

...ut

spring srew for the 2 extruder versions

1x 35/40 mm hexagonal head + nut

short zge spring pressure guide

2x 4mm x 18mm pin

cg_trader

$6

Mai Gudo | 3D

...i will see if i can sort it out. mountain landscape volcano terrain environment nature photogrammetry elevation dem science other

Neotko

thingiverse

free

Mandalorian Inspired Ring 21mm (scale to your size ofc)

...your size ofc) thingiverse made it for fun for myselfhttps://twitter.com/neotkostatus/1217354724774764544?s=20 two versions, i like the shorter more now...

thingiverse

free

Mark 2 for UM2 and UM3 Cores by Gudo (Charles Guy Doppia)

...action. https://www.youtube.com/watch?v=fcd_mkgqaqo https://www.youtube.com/watch?v=9jgf3s_j_u4 please, share, post and comment on twitter/neotko since i rarely go to um forum anymore and...

thingiverse

free

East3D Part Coolers Blower Fans Mount by MegaMaking

...mount by megamaking thingiverse this design is inspired by neotko design, however, it is a complete remake without modifying...

thingiverse

free

Titan E3D - East3DGecko 35x35x10 Delta Blowers Fancap by Neotko

... bad in my experience for this but can work for a few months) will get deformed over time, so print more than 1 set just in case.

thingiverse

free

2020 Aluminium Extrusion Spool Holder for East3DGecko by Neotko

...y are your spools.

it's a beta and might give troubles, but i wanted something printable fast and easy to use or reposition.

thingiverse

free

BCN Sigma Spacer for Mirror & Dual Modes & DISCO MODE ? by Neotko

...stions i answer much faster on twitter, if you leave a comment here spec slow speed on my answers.

http://www.twitter.com/neotko

thingiverse

free

Beyond UMO & UM2 Slideblocks by Gudo & Neotko - GT2 Open Belt by Neotko

...ideblock. you can a) glue it, b) fuse with heat a bit the plastics so it never moves or c) print very slow and use the tight fit.

thingiverse

free

UMO / UM2 - Experimental Vibration dampening foots by Neotko

...ananas sometimes when doing jobs with different heights.

thanks to iroberti and gudo for the input and ideas to make this better.

thingiverse

free

Zero Gravity Extruder Direct Drive by Gudo & Neotko by Neotko

...ut

spring srew for the 2 extruder versions

1x 35/40 mm hexagonal head + nut

short zge spring pressure guide

2x 4mm x 18mm pin

Doppia

3ddd

$1

Lumina Matrix Doppia suspension

...ina

наименование: matrix doppia suspension

фабрика: lumina

высота: 2000мм

ширина: 820мм

глубина: 110мм

материал: метал, стекло

3ddd

free

Paolo Lucchetta / art92 porta doppia

... дверь , двухстворчатые двери

http://www.paololucchetta.com/

3ddd

$1

Lumina Matrix

...lumina matrix 3ddd doppia , lumina , matrix светильник matrix doppia от фабрики...

3ddd

$1

Doppia T - P/633

...doppia t - p/633

3ddd

кресло

office chair doppia t - p633

thingiverse

free

Pwnagotchi alternative case rpi 0 by Bendercrusoe

...di molti box, il sistema di carene è a doppia azione, non solo protegge le componenti interne, ma le...

thingiverse

free

Sapphire PRO, supporto estrusore Orbiter by andreabonuc

...andreabonuc thingiverse supporto estrusore orbiter per sapphire pro. richiede doppia foratura m3 sul supporto...

thingiverse

free

Doppia girandola /Double pinwhell by vidatox

...inwhell by vidatox

thingiverse

doppia girandola, necessita di uno stuzzicadenti

-

double pinwhell, need a toothpick for the pin

thingiverse

free

Box Alimentatore USB Smartphone by Krashone

...per contenere il circuito di un'alimentatore usb economico con doppia usb, acquistabile in qualsiasi negozio di elettronica. il box...

3d_sky

free

Doppia T - P/633

...doppia t - p/633

3dsky

office chair doppia t - p633

3d_sky

free

Lumina Matrix

...lumina matrix 3dsky lamp factory of lumina doppia ...

Xy

3ddd

$1

Honeycomb Floor

...паркет parquet with metalic honeycomb floor demensions 500x500 cm xy multitexture +...

3ddd

$1

holly hunt xy bench

...eight: 17.75 in

width: 45 in, 26 in

depth: 18 in

больше превьюhttps://www.behance.net/gallery/24983999/bench-3d-model?

3ddd

$1

pillows bed 2

...pillows bed 2 3ddd подушка , круглая dimensions: xy ...

3ddd

$1

Вешалка напольная XY-027

...а штанги: 171 см

диаметр основания: 38 смhttp://mebelshopos.ru/aksessuary-ofisnye/veshalka-napolnaya-xy-027-detail.html

3d_export

$180

optical fiber laser marking machines assembly

...fiber laser marking machine<br>automatic loading and unloading laser marking machine<br>xy platform adjustable laser marking machine<br>laser marking machine used with...

3d_export

$9

positioning mechanism of heavy-duty platform

...activity -- ball mechanism activity ---- drive heavy load xy axis movement -- positioning completed<br>**************************************<br>files format contains<br>-solidworks 2017<br>-step<br>-iges<br>- and...

3d_export

$7

positioning screw mechanism

...and lead screw, constitute a double displacement adjustable mechanism, xy axis double position adjustable positioning.<br>**************************************<br>files format contains<br>-solidworks 2017<br>-step<br>-iges<br>- and...

thingiverse

free

Atlas lamp by nahojjjen

...and "mmm_75" variants. the 100% size needs a print xy area of at least 23x23cm, and the 75% needs...

thingiverse

free

PrusaSlicer profile for Easythreed X1 + extensive explanation of each setting by JacekJagosz

...prints to not fit on the bed. support - xy separation between between an object and its support 50%...

thingiverse

free

Iterated System Bamboo Shoots by TheHappyMew

...center of the cylinder from its origin in the xyplane (that i'll call [0,0] for reference, but know that...

Charles

3ddd

$1

Charles Modular 3,5 ST&Chaise Longue

...illermot , капитоне , угловой

design guillermot

3d_ocean

$7

Herman Miller Eames Molded Plastic Chair

...herman miller eames molded plastic chair 3docean body chair charles clean cradle design detailed eames first forms herman high...

3d_ocean

$14

Charles Chair

...charles chair

3docean

3ds c4d chair charles chair furniture indoor interior obj

corona render

3d_export

$50

Pollock Executive Chair 3D Model

...executive chair 3d model 3dexport knoll pollock executive chair charles pollock executive chair 3d model download .c4d .max .obj...

3ddd

$1

OLIGO flight line Charles

...oligo flight line charles

3ddd

oligo

в архиве присутствует fbx формат а также модель в 2011 версии макса.

3ddd

$1

Vitra wire chair DKW

...dkw 3ddd vitra vitra wire chair. model dkw, by charles & ray eames,...

3ddd

$1

Charles Paris Propylees Floor Lamp L

...mp l

3ddd

charles , paris , propylees

400xh2050

cg_studio

$29

Couch B&B; ITALIA CHARLES3d model

... bedroom

.obj .max .fbx - couch b&b italia charles 3d model, royalty free license available, instant download after purchase.

3ddd

$1

Titanic Lamp

...titanic lamp 3ddd английский дизайнер чарльз тревельян (charles trevelyan) разработал для компании “fluke” светильник “titanic”. высота: 45...

3ddd

$1

Charles Table

...charles table

3ddd

письменный

charles table

Guy

3d_export

$69

MAN 02 3D Model

...polygon game swimming pool character male man fbx people guy realtime person maya human sport max summer beach man...

3ddd

$1

Christopher Guy 76-0150

...topher guy , журнальный

стол журнальный, christopher guy 76-0150, италия (1300*1300*400)

3ddd

$1

Christopher guy 095-60-0253

...mensions

h 76. w 275. d 103 cm

measurements notes

seat width: 230 cm. seat depth: 65 cm. seat height: 45 cm. arm height: 76 cm

3ddd

$1

Christopher Guy Chair 30-0044

... guy

страна изготовитель: сша

дизайнер\коллекция: -/-

описание: chair/стул

сайт:http://www.christopherguy.com/index.php

3ddd

$1

Christopher Guy

...christopher guy

3ddd

christopher guy

размеры

длина: 120 см

ширина: 70 см

высота: 45 см

3ddd

$1

Christopher Guy Archer

...christopher guy archer

3ddd

christopher guy

стул christopher guy archer (30-0002)

3ddd

$1

Vespa

...vespa 3ddd christopher guy , журнальный christopher guy vespa (76-0123) a delightful end...

3ddd

$1

Зеркало

...christopher guy модель зеркало christopher guy 630mm * 1100mm ссылкаhttp://www.christopherguycom/details_search.php?idt_product=343&finish;_id=107&idt;_tag=92&idt;_tag_child=166-165 ...

3ddd

$1

Christopher Guy Chair 60-0411

...christopher guy chair 60-0411

3ddd

christopher guy

christopher guy arpa seating › 60-0411

w75, d71, h103

3ddd

$1

Christopher Guy 50-2864

...christopher guy 50-2864

3ddd

christopher guy

антикварное овальное зеркало с рамой из 350 мозаик, ручной работы.

Core

3d_ocean

$7

Glass Door Monoblock 005

...glass door monoblock 005 3docean architecture brass building components core door entrance entry garage glass handle hinge hollow interior...

3d_ocean

$7

Glass Door Monoblock 008

...glass door monoblock 008 3docean architecture brass building components core door entrance entry garage glass handle hinge hollow interior...

3d_ocean

$7

Glass Door Z 006

...glass door z 006 3docean architecture brass building components core door entrance entry garage glass handle hinge hollow interior...

3d_ocean

$7

Glass Door Standart 006

...glass door standart 006 3docean architecture brass building components core door entrance entry garage glass handle hinge hollow interior...

3d_ocean

$7

Glass Door Monoblock 003

...glass door monoblock 003 3docean architecture brass building components core door entrance entry garage glass handle hinge hollow interior...

3d_ocean

$7

Glass Door Monoblock 006

...glass door monoblock 006 3docean architecture brass building components core door entrance entry garage glass handle hinge hollow interior...

3d_ocean

$7

Glass Door L 002

...glass door l 002 3docean architecture brass building components core door entrance entry garage glass handle hinge hollow interior...

3d_ocean

$7

Glass Door Z 002

...glass door z 002 3docean architecture brass building components core door entrance entry garage glass handle hinge hollow interior...

3d_ocean

$7

Glass Door L 004

...glass door l 004 3docean architecture brass building components core door entrance entry garage glass handle hinge hollow interior...

3d_ocean

$7

Glass Door L 005

...glass door l 005 3docean architecture brass building components core door entrance entry garage glass handle hinge hollow interior...