GrabCAD

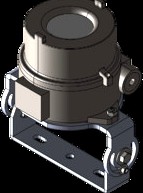

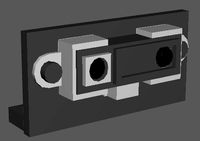

Explosion Proof Motion Sensor - 10' to 20' Mounting Height - 15' x 15' Area - Adjustable Timer - HV

by GrabCAD

Last crawled date: 3 years, 2 months ago

http://www.larsonelectronics.com/p-144579-explosion-proof-motion-sensor-10-to-20-mounting-height-15-x-15-area-adjustable-timer-hv.aspx

The Larson Electronics EXP-MS-N4X-AT-HV Explosion Proof motion sensor is approved Class 1 Division 1 & 2 and Class 2 Division 1 & 2 and the ability to power lights or other equipment within hazardous locations based on motion. This C1D1 rated motion sensor features adjustable sensitivity and time delay after motion.

This explosion proof motion sensor is ideal for operators seeking a high quality explosion proof motion sensor rated for use in hazardous areas designated Class 1 Division 1 and Class 2 Division 1. This explosion proof motion detector can be mounted at heights ranging from 10' up to 20' above the ground and provides up to 15' by 15' coverage when mounted at 16'. The entire unit is constructed of copper free non-sparking aluminum construction with a glass window for motion detection. This unit is easily wall mounted via integral mounting bracket, which can be adjusted -90° to +30° vertically after installation. The explosion proof housing provides two 1/2" or 3/4" hub openings located on either side of the housing for running electrical conductors in a feed through configuration. A bushing seal at each conductor opening prevents damage to wiring insulation.

This unit is designed to operate on 120V, 208V, 220V, 240V, or 277V AC electrical circuits. We also low voltage 12-24V AC or DC electrical systems. This motion sensor is suitable for use in environments where combustible dusts and particulates may be present.

1/2" or 3/4" NPT tapped conduit openings are provided on either of the unit in feed through versions while dead end versions have a single conduit hub, providing easy and secure connection to main power line supplies.

Suggested Applications: Manufacturing, Industrial, Warehouse, Lighting, Lighting, Wet areas or Locations Where Combustible Dust is Present.

The Larson Electronics EXP-MS-N4X-AT-HV Explosion Proof motion sensor is approved Class 1 Division 1 & 2 and Class 2 Division 1 & 2 and the ability to power lights or other equipment within hazardous locations based on motion. This C1D1 rated motion sensor features adjustable sensitivity and time delay after motion.

This explosion proof motion sensor is ideal for operators seeking a high quality explosion proof motion sensor rated for use in hazardous areas designated Class 1 Division 1 and Class 2 Division 1. This explosion proof motion detector can be mounted at heights ranging from 10' up to 20' above the ground and provides up to 15' by 15' coverage when mounted at 16'. The entire unit is constructed of copper free non-sparking aluminum construction with a glass window for motion detection. This unit is easily wall mounted via integral mounting bracket, which can be adjusted -90° to +30° vertically after installation. The explosion proof housing provides two 1/2" or 3/4" hub openings located on either side of the housing for running electrical conductors in a feed through configuration. A bushing seal at each conductor opening prevents damage to wiring insulation.

This unit is designed to operate on 120V, 208V, 220V, 240V, or 277V AC electrical circuits. We also low voltage 12-24V AC or DC electrical systems. This motion sensor is suitable for use in environments where combustible dusts and particulates may be present.

1/2" or 3/4" NPT tapped conduit openings are provided on either of the unit in feed through versions while dead end versions have a single conduit hub, providing easy and secure connection to main power line supplies.

Suggested Applications: Manufacturing, Industrial, Warehouse, Lighting, Lighting, Wet areas or Locations Where Combustible Dust is Present.

Similar models

grabcad

free

Explosion Proof Motion Sensor - 10' to 20' Mounting Height - 15' x 15' Area - Adjustable Timer - LV

...applications: manufacturing, industrial, warehouse, lighting, lighting, wet areas or locations where combustible dust is present.

grabcad

free

Explosion Proof Motion Sensor - 10' to 20' Mounting Height - 15' x 15' Area - Adjustable Timer - LV

...applications: manufacturing, industrial, warehouse, lighting, lighting, wet areas or locations where combustible dust is present.

grabcad

free

400W Explosion Proof Motion Sensor - 20' to 25' Mounting Height - 15' x 15' Area Coverage - Timer

...applications: manufacturing, industrial, warehouse, lighting, lighting, wet areas or locations where combustible dust is present.

grabcad

free

Explosion Proof On/Off Switch - Class I, Div. 1 & 2 - Class II, Div. 1 & 2 - 20 Amp Rated

...applications: manufacturing, industrial, warehouse, lighting, lighting, wet areas or locations where combustible dust is present.

grabcad

free

Explosion Proof Switch - Class 1 Div 1 and Class 2 Div 1

...applications: manufacturing, industrial, warehouse, lighting, lighting, wet areas or locations where combustible dust is present.

grabcad

free

Explosion Proof Switch for EPL-48-2L Series

...applications: manufacturing, industrial, warehouse, lighting, lighting, wet areas or locations where combustible dust is present.

grabcad

free

Explosion Proof Three Way Switch - Class I, Div. 1 & 2 - Class II, Div. 1 & 2 - 20 Amp Rated

...applications: manufacturing, industrial, warehouse, lighting, lighting, wet areas or locations where combustible dust is present.

grabcad

free

Explosion Proof SPST Three Phase Starter Switch - Copper Free Aluminum - 30 Amp Rated - C1D1 C2D1

...applications: manufacturing, industrial, warehouse, lighting, lighting, wet areas or locations where combustible dust is present.

grabcad

free

Explosion Proof Junction Box with Six 1-inch Hubs

...cu. in.

ratings:

class 1, divisions 1 & 2, groups c & d

class 2, division 1, groups e, f, g

class 3, divisions 1 & 2

grabcad

free

Explosion Proof Combination Dimming/On/Off Switch - 0-10V Dimming - C1D1&2 - C2D1&2 - Class III

...applications: manufacturing, industrial, warehouse, lighting, lighting, wet areas or locations where combustible dust is present.

Hv

3ddd

$1

Tobias Grau BILL HV + LED

...tobias grau bill hv + led

3ddd

tobias grau

tobias grau bill hv + led

3ddd

$1

Мясорубка MOULINEX ME 6061 HV 8

...ка moulinex me 6061 hv 8

3ddd

мясорубка , moulinex

"moulinex" прослужит долго)

cg_studio

$129

Republic P-47D Thunderbolt - HV-A - Lt.Col. F.S.Gabreski3d model

...public p-47d thunderbolt - hv-a - lt.col. f.s.gabreski 3d model, royalty free license available, instant download after purchase.

3ddd

$1

Hudson Valley Lighting Mansfield Transitional Foyer Light HV-1315

...5

материал: polished nickel

d=15" / 38 cm

url:http://www.hudsonvalleylighting.com/productdetails.aspx?item=1315-pn

3ddd

$1

Occhio, Sento, faro singolo

...occhio, sento, faro singolo 3ddd occhio http://www.occhio.de/en/products/occhio-system/sento/ceiling-lamps/faro-singolo/hv ...

3dfindit

free

HV

...hv

3dfind.it

catalog: festo

3dfindit

free

HV

...hv

3dfind.it

catalog: festo

thingiverse

free

hv pylon by Syzguru11

...hv pylon by syzguru11

thingiverse

hv pylon

3dfindit

free

HV Series

...hv series

3dfind.it

catalog: wain electrical

thingiverse

free

HV transformer housing by zomtronic

...hv transformer housing by zomtronic

thingiverse

hv transformer housing with cover

Timer

turbosquid

$5

timer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Timer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

design_connected

$9

Two Timer

...two timer

designconnected

established & sons two timer computer generated 3d model. designed by industrial facility.

3d_export

free

sand timer

...sand timer

3dexport

turbosquid

$49

Hourglass Sand Timer

...alty free 3d model hourglass timer for download as ma and obj on turbosquid: 3d models for games, architecture, videos. (1431455)

turbosquid

$3

Electronic timer panel

...alty free 3d model electronic timer panel for download as max on turbosquid: 3d models for games, architecture, videos. (1363343)

3d_ocean

$18

Red Kitchen Timer

...er with aluminium elements. available formats: • max scanline • max vray • max mentalray • cinema 4d • cinema 4d vray • fbx • obj

turbosquid

$7

Darkroom Interval Timer

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$7

bombe c4 timer variable

...bombe c4 timer variable

3dexport

bombe c4 + timer variable + texture<br>obj . c4d . fbx . stl

3d_export

$13

Kitchen Timer 3D Model

...terior home house 3ds max cinema c4d mental ray fbx obj detailed cgaxis vray kitchen

kitchen timer 3d model cgaxis 52497 3dexport

Proof

turbosquid

$6

bullet proof jacket

...el bullet proof jacket for download as 3ds, obj, fbx, and dae on turbosquid: 3d models for games, architecture, videos. (1193147)

turbosquid

$149

Bullet Proof Vest with molle attachments

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$40

chevrolet nova ss 70 death proof

...chevrolet nova ss 70 death proof

3dexport

3d_export

$9

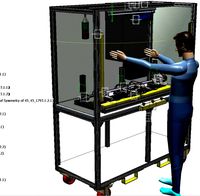

of automobile component error proofing system

...cific product defects; the other is to check the products one by one through cheap means to determine whether they are qualified.

3d_export

$16

yb2 high voltage explosion proof series three phase asynchronous motor 9 specifications in total

...cifications in total

3dexport

yb2 high voltage explosion proof series three phase asynchronous motor (9 specifications in total)

turbosquid

$2

Replacement RC Car Shock Proof Plank SJ11 Accessory Spare Parts 15-SJ11 for GPTOYS S911 S912 And Others

...1 for gptoys s911 s912 and others for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1193732)

3d_ocean

$1

Insulation Felt Seamless Pattern Background

...background 3docean background carpet ceilings closeup cloth cover dust proof fabric felt fiber fleece gray insulation insulation felt material...

3d_export

$20

Passport Collection 3D Model

...3dexport passport us usa united states travel document citizenship proof booklet realistic textures russia uk great britain france collection...

3d_ocean

$6

Duck

...3docean 3d printing animals bird car chrome creative death proof duck duck emblem metal model sculpture soot souvenirs trinkets...

3ddd

$1

Paloma

...protection. 100% recyclable. high mechanical resistance, made in great collision-proof ...

Explosion

3d_export

$6

explosion

...explosion

3dexport

3 d of explosion

3d_export

$10

explosion

...explosion

3dexport

3d model of explosion for 3d printing

turbosquid

$5

Explosion

...rbosquid

royalty free 3d model explosion for download as max on turbosquid: 3d models for games, architecture, videos. (1202603)

3d_export

$10

Explosion

...explosion

3dexport

turbosquid

$14

Explosion

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Explosive

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$3

Explosive Barrel

...explosive barrel 3docean barrel decoration explosion explosive industrial low low poly metal object old poly...

3ddd

free

KOLARZ Serie Explosion

... serie explosion , австрия

kolarz serie explosion 0109.118.5.kot. врай. текстуры.

3d_export

$5

atomic bomb explosion

...atomic bomb explosion

3dexport

atomic bomb explosion

turbosquid

$1

explosives pack

...squid

royalty free 3d model explosives pack for download as on turbosquid: 3d models for games, architecture, videos. (1316376)

Motion

3ddd

$1

Fabbian Motion

...motion

3ddd

fabbian , motion

светильник fabbian коллекция motion. текстурка в комплекте.

design_connected

$7

Motion Notion

...motion notion

designconnected

howard miller motion notion computer generated 3d model. designed by nelson, george.

turbosquid

$10

motion shark

...squid

royalty free 3d model motion shark for download as rib on turbosquid: 3d models for games, architecture, videos. (1261380)

3d_ocean

$6

Motion Set

...ng face and vertex, three file format are included,very useful for motion graphic artist , total poly 143.952 total vertex 79.952

3d_export

$10

Motion Tracker Aliens

...er out moving objects from stationary background and then displayed them on the monitor as a series of contours of probable loci.

3d_export

$6

motion stand for book and logo

...motion stand for book and logo

3dexport

motion stand for book and logo

3d_export

$6

Reciprocating Motion

...#39;vinci's reciprocating motion contraption the model is used for picking up buckets of water from a well materials included

3d_export

$15

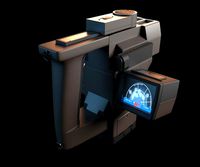

M314 Motion Tracker Aliens

...ng objects from stationary background and then displayed them on the m314's monitor as a series of contours of probable loci.

3d_ocean

$5

low poly perpetual motion model

...chnology

low poly perpetual motion model available in the obj format. this model is suitable for decoration. available in 1 model

turbosquid

$10

Realistic monitor for motion graphic

... monitor for motion graphic for download as obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1348300)

Sensor

3d_export

free

parking sensor

...parking sensor

3dexport

car parking sensor

turbosquid

$1

Sensor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

Smoke sensor

...port

smoke sensor, can be an impressive element for your projects. easy to use, realistic image, low polygon, quality materials.

3d_export

$5

Air Quality Sensor v1

...air quality sensor v1

3dexport

air quality sensor v1

3d_export

$15

float sensor

...e up render. - all parts and materials are logically named. other formats ================= - collada (.dae) - autodesk fbx - obj

3d_export

$5

ultrasound sensor

...ivers convert ultrasound into electrical signals, and transceivers can both transmit and receive ultrasound. export in: -obj -fbx

3ddd

free

Вытяжка Shindo pallada sensor

... вытяжка

вытяжка shindo pallada sensor. в двух размерах - 600 и 900. текстуры в комплекте.

3d_export

$5

Parking Sensor Bracket for Nissan X-Trail

...parking sensor bracket for nissan x-trail

3dexport

parking sensor bracket for nissan x-trail. s/n 28533-4cc5d

3ddd

free

Shindo Pallada sensor 60 BBG 4ETC

...or 60 bbg 4etc

3ddd

shindo , вытяжка

вытяжка купольная shindo pallada sensor 60 bbg 4etc

3d_export

$26

Solar Highway Traffic Sensor 3D Model

...uespace cob 3ds dxf obj directx freeway street element textures

solar highway traffic sensor 3d model visualmotion 51156 3dexport

15

3d_export

$5

Iphone 15

...iphone 15

3dexport

apple iphone 15

3ddd

$1

Bed 15

...bed 15

3ddd

постельное белье

bed 15

design_connected

$13

Ella 15

...ella 15

designconnected

delightfull ella 15 computer generated 3d model.

design_connected

$27

Kilt 15

...kilt 15

designconnected

zanotta kilt 15 computer generated 3d model. designed by progetti, emaf.

design_connected

$22

Domino 15

...domino 15

designconnected

zanotta domino 15 computer generated 3d model. designed by progetti, emaf.

design_connected

$9

SMTV 15

...smtv 15

designconnected

maxalto smtv 15 computer generated 3d model. designed by citterio, antonio.

design_connected

$25

Docks 15

...docks 15

designconnected

gandia blasco docks 15 computer generated 3d model. designed by romero vallejo.

design_connected

$7

Bolla 15

...bolla 15

designconnected

gervasoni bolla 15 coffee tables computer generated 3d model. designed by michael sodeau.

3ddd

$1

Curtains 15

...curtains 15

3ddd

curtains 15

polys: 331066

other models:http://3ddd.ru/users/brast/models

3d_export

$6

tap-15

...tap-15

3dexport

Area

3d_export

$15

exposicion area

...exposicion area

3dexport

exhibition area from urban space and squares / area de exibición para espacios urbanos y plazas

3ddd

$1

Porada Area

... area

area

design: w. mandelli - w. selva

chair completely covered by leather with metal frame.

3d_export

$5

Recreation area

...recreation area

3dexport

my very first design of a recreation area with panoramic windows.

design_connected

$7

Area pouf

...area pouf

designconnected

lammhults mobel area pouf benches computer generated 3d model. designed by anya sebton .

3d_ocean

$7

Child Park Area

...child park area

3docean

child child area child game child park area child park horse playgrounds

child park area ,playground

design_connected

$11

Area Table

...area table

designconnected

b&b italia area table computer generated 3d model. designed by piva, paolo.

3d_export

$12

Modern reception area

...modern reception area

3dexport

modern reception area

turbosquid

$55

Living area

...osquid

royalty free 3d model living area for download as max on turbosquid: 3d models for games, architecture, videos. (1500200)

turbosquid

$25

Cofee Area

...bosquid

royalty free 3d model cofee area for download as max on turbosquid: 3d models for games, architecture, videos. (1333805)

turbosquid

$10

Living area

...osquid

royalty free 3d model living area for download as max on turbosquid: 3d models for games, architecture, videos. (1625079)

Adjustable

3d_ocean

$7

Adjustable Wrench

...adjustable wrench

3docean

adjustable wrench highly detailed wrench

highly detailed adjustable wrench.

3ddd

$1

Adjustable Stool

...adjustable stool

3ddd

табурет

wooden adjustable stool.

3d_ocean

$20

Adjustable Gym Bench

...st adjustable bench black equipement gym gymnastic indoor silver sport workout

3d model of black and silver adjustable gym bench.

3d_ocean

$20

Adjustable Gym Bench

...st adjustable bench black equipement gym gymnastic indoor silver sport workout

3d model of black and silver adjustable gym bench.

3d_ocean

$16

Adjustable Weight Bench

...arbell bench black equipement gym gymnastic indoor sport weight workout

3d model of black adjustable weight bench with a barbell.

turbosquid

$5

Adjustable wrench

...

royalty free 3d model adjustable wrench for download as fbx on turbosquid: 3d models for games, architecture, videos. (1313414)

3d_export

$5

adjustable tension lock

...adjustable tension lock

3dexport

adjustable tension lock

3d_export

$5

Adjustable key

...adjustable key

3dexport

turbosquid

$1

Adjustable Table

...e 3d model adjustable table for download as 3dm, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1542005)

turbosquid

$1

Adjustable Dumbbell

...el adjustable dumbbell for download as obj, fbx, dae, and stl on turbosquid: 3d models for games, architecture, videos. (1460890)

20

3d_export

$15

rocks 20

...rocks 20

3dexport

rocks 3d model 20

3ddd

$1

DECOR MEDIEVO 20*20 MIX

...ллекция: bolonia

фабрика: mainzu

страна: испания

размер: 20x20 см

ссылка:http://www.mainzu.com/bolonia.php#prettyphoto

3d_export

$6

tap-20

...tap-20

3dexport

3ddd

$1

Bed 20

...bed 20

3ddd

постельное белье

bed 20. i hope you like it

software : 3dsmax + md + vray 2.4

3d_export

$5

houseberg home 20

...houseberg home 20

3dexport

houseberg home 20

3d_export

$5

silla 20

...silla 20

3dexport

3ddd

$1

BAMBOO PLANTS 20

...bamboo plants 20

3ddd

кашпо , цветок

bamboo plants 20

3d_export

free

commode 01-20

...commode 01-20

3dexport

commode 01-20 from ikea

3d_export

free

sofa 02-20

...sofa 02-20

3dexport

sofa 02-20 from ikea

turbosquid

$8

Bath 20

... free 3d model bath 20 for download as max, dxf, fbx, and dwg on turbosquid: 3d models for games, architecture, videos. (1275772)

Height

turbosquid

$5

Height Stool

...ree 3d model height stool for download as blend, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1703076)

cg_studio

$20

Height Gauge3d model

...ndustrial height gauge tool indutsrial

- height gauge 3d model, royalty free license available, instant download after purchase.

turbosquid

$6

4.5 meters in height

...oyalty free 3d model 4.5 meters in height for download as max on turbosquid: 3d models for games, architecture, videos. (1213038)

turbosquid

$1

Counter Height Stool

... model counter height stool for download as obj, dae, and skp on turbosquid: 3d models for games, architecture, videos. (1318792)

3ddd

free

Stanley furniture - Avalon heights

...stanley furniture - avalon heights

3ddd

stanley furniture

stanley furniture - avalon heights metal base empire writing desk

3d_ocean

$1

Maximum height sign

...ure applied. the object is ready to import and render in both formats. the model has been built to be able to subdivide flawle...

turbosquid

$20

Low height cabinet design

...y free 3d model low height cabinet design for download as max on turbosquid: 3d models for games, architecture, videos. (1402496)

turbosquid

$5

170cm height dual lamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_ocean

$1

Maximum height sign

...lied. the object is ready to import and render in both formats. the model has been built to be able to subdivide flawlessly fo...

3d_export

$5

Maximum height sign 3D Model

...hicle motor way traffic car pedestrian signal circle round stop junction

maximum height sign 3d model dragosburian 89408 3dexport

10

turbosquid

$10

a-10

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3ddd

$1

EX 10

...ex 10

3ddd

samsung , фотоаппарат

ex 10

3ddd

$1

Bed 10

...bed 10

3ddd

постельное белье

bed 10

evermotion

$25

Scene 10 Archinteriors vol. 10

...dering design interior

take a look at textured and shadered visualization scene ready to be rendered.. evermotion 3d models shop.

3ddd

$1

Curtains 10

...curtains 10

3ddd

curtains 10

3ds max 2011,fbx + textures

polys: 100355

3ddd

free

PLANTS 10

...plants 10

3ddd

цветок , горшок

plants 10,, with 3 different color planter boxes

design_connected

$29

Nuvola 10

...nuvola 10

designconnected

gervasoni nuvola 10 computer generated 3d model. designed by navone, paola.

design_connected

$22

Kilt 10

...kilt 10

designconnected

zanotta kilt 10 computer generated 3d model. designed by progetti, emaf.

design_connected

$11

Domino 10

...domino 10

designconnected

zanotta domino 10 computer generated 3d model. designed by progetti, emaf.

design_connected

$20

Docks 10

...docks 10

designconnected

gandia blasco docks 10 computer generated 3d model. designed by romero vallejo.

Mounting

3d_export

free

mounting bracket

...mounting plate is the portion of a hinge that attaches to the wood. mounting plates can be used indoors, cabinetry and furniture.

turbosquid

$2

MOUNTING

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mounts

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Mount Fuji

...fuji

turbosquid

free 3d model mount fuji for download as obj on turbosquid: 3d models for games, architecture, videos. (1579977)

3d_export

$5

Headphone mount LR

...headphone mount lr

3dexport

headphone mount l+r

turbosquid

$5

pipe mounting

...quid

royalty free 3d model pipe mounting for download as obj on turbosquid: 3d models for games, architecture, videos. (1293744)

3d_export

$5

Magnetic GoPro Mount

...pro mount

3dexport

cool magnetic mount for gopro. allows you to mount the camera on flat metal surfaces and get exclusive shots.

turbosquid

$5

Stone Mount

...ty free 3d model stone mount for download as ma, obj, and fbx on turbosquid: 3d models for games, architecture, videos. (1370306)

3ddd

$1

Wall Mounted Basin

...wall mounted basin

3ddd

high detailed wall mounted basin

material included

turbosquid

$5

TV with mount

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.