GrabCAD

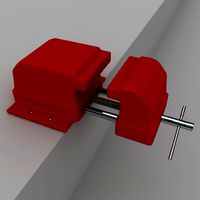

COVID_CLAMP

by GrabCAD

Last crawled date: 1 year, 10 months ago

Attribution-NonCommercial-ShareAlike

CC BY-NC-SA

Because of the covid 19 crisis in early 2020, I was contacted by a local second year medical student from the University of Ottawa, Mina Boshra, who was interested in designing a 3D printed clamp for the intubation tubing used on the hospitals ventilators. Mina has an interest in curating CAD models for medical uses. He received feedback from the doctors with which he was working, that they were running out of the standard and expensive kosher clamps (typical used in surgeries). They wanted to see if a cost effective 3d printed alternative could be used.

I worked on the design for a few weeks, with many iterations along the way. I didn't have access to the correct tubing from the beginning so I used a stand in tube for the first iterations which was too soft. We quickly realized that this wouldn't work so Mina shipped the correct tube and I was able to move forward quickly. The original design iterations focused on keeping things simple and included an integrated flexible hinge, but the 11mm intubation medical tubing has VERY thick walls and is not easily squeezed. It requires ALOT of force to get it to a full flow stop closure. My original designed weren't going to work, the plastic hinge wasn't strong enough. The design evolved into a "pliers" type design with integrated latch clip. I feel this is the only method to allow for the sort of force necessary to get a full stop closure.

Print details:

No raft

LH = .15-.25

Infill = 40%+

M5 screw, 20-25mm long, use a 13/64 drill bit to clean up the hole

Your job:

Distribute this file around the world, built upon it and make it better. This design works great but one of the requests of the doctors was to have it be removable with one hand. The current design requires two handed removable. I think with some tweaking to the latch, it could be made to hold closed, yet still be able to be flicked open with a little pressure from fingers. Also, I wanted to test out if a 3d printed "bolt" or pivot could work instead of having to use an M5 bolt. This way there would be no need to source the hardware....

For further details regarding this project, please contact

Mina Boshra

mbosh103@uottawa.ca

or myself

truespecID@gmail.com

Let's help save some lives.

CC BY-NC-SA

Because of the covid 19 crisis in early 2020, I was contacted by a local second year medical student from the University of Ottawa, Mina Boshra, who was interested in designing a 3D printed clamp for the intubation tubing used on the hospitals ventilators. Mina has an interest in curating CAD models for medical uses. He received feedback from the doctors with which he was working, that they were running out of the standard and expensive kosher clamps (typical used in surgeries). They wanted to see if a cost effective 3d printed alternative could be used.

I worked on the design for a few weeks, with many iterations along the way. I didn't have access to the correct tubing from the beginning so I used a stand in tube for the first iterations which was too soft. We quickly realized that this wouldn't work so Mina shipped the correct tube and I was able to move forward quickly. The original design iterations focused on keeping things simple and included an integrated flexible hinge, but the 11mm intubation medical tubing has VERY thick walls and is not easily squeezed. It requires ALOT of force to get it to a full flow stop closure. My original designed weren't going to work, the plastic hinge wasn't strong enough. The design evolved into a "pliers" type design with integrated latch clip. I feel this is the only method to allow for the sort of force necessary to get a full stop closure.

Print details:

No raft

LH = .15-.25

Infill = 40%+

M5 screw, 20-25mm long, use a 13/64 drill bit to clean up the hole

Your job:

Distribute this file around the world, built upon it and make it better. This design works great but one of the requests of the doctors was to have it be removable with one hand. The current design requires two handed removable. I think with some tweaking to the latch, it could be made to hold closed, yet still be able to be flicked open with a little pressure from fingers. Also, I wanted to test out if a 3d printed "bolt" or pivot could work instead of having to use an M5 bolt. This way there would be no need to source the hardware....

For further details regarding this project, please contact

Mina Boshra

mbosh103@uottawa.ca

or myself

truespecID@gmail.com

Let's help save some lives.

Similar models

thingiverse

free

Print in Place - Click Box with Hinge & Latch by fgebhart

...s stuff. the dimensions of the box are 40x40x20mm.

have fun printing!

also check the remixed design: anti moisture silica gel box

thingiverse

free

1" Tube Clamp by Freds_Optix_Hardware

...se

a 2-piece print. i've printed and used a number of these with pla.

a new version is coming soon with a hinge on one end.

thingiverse

free

M5 T-Slot Clamp

...85". i printed laying flat on the side, with support in the thru hole. support could easily be knocked out after printing.

thingiverse

free

Clamp for filament-tube by atzeton

...atzeton

thingiverse

i didn't like the "spreading" tubes so i designed those small clamps. now it's all proper.

thingiverse

free

Hemostat by CaptainKirk

...c (i used abs) the hinge has a limited life. i kept flexing one until it broke, about 70 flexes. when it breaks, print another.

thingiverse

free

3/4" Conduit Clamp - "F" Style by MStence

...like the other end. they both seem to have similar holding strength. the latch version of the live end...

thingiverse

free

sliding clamp - bag closure - tool holder - linear guided lock by felge4fingers

...o slide the clamp up to 90mm...

the clamp is fixed by an m5 screw/nut and the hole thing can be sfixed with 2 screws up to 6.5mm.

thingiverse

free

Plano 737 777 771 7777 Fishing Tackle Box Latch and Hinge by gordineerpeter

...latch on 737 boxes, but should work for various similar models, and bottom latches should be the same. i...

thingiverse

free

Cap with Handle for XRT and ASR Threads by sgtbsimms

...quot; pvc pipe. that pipe could be clamped in a vise, stuck in my lawn, leaned against my work bench, etc while the paint dried.

thingiverse

free

BRUDER Crane Clamp Connector by Wulfher

...ent part for my son's bruda truck. he broke the hinge between the clamp and the extender arm and no glue could hold the load.

Covid

turbosquid

$6

covid

...d

turbosquid

royalty free 3d model covid for download as max on turbosquid: 3d models for games, architecture, videos. (1667862)

3d_export

$50

covid-19

...covid-19

3dexport

3d obj model. covid-19

3d_export

$11

covid-19

...covid-19

3dexport

this is 3d model about covid-19 virus

3d_export

$10

covid 3d mask

...covid 3d mask

3dexport

3d covid mask for 3d avatars to implement in covid information projects

3d_export

$5

covid-19 korona

...covid-19 korona

3dexport

covid-19

3d_export

$8

coronavirus covid-19

...coronavirus covid-19

3dexport

coronavirus covid-19

3d_export

$5

covid mask black

...covid mask black

3dexport

black covid mask

3d_export

$5

coronavirus covid-19

...coronavirus covid-19

3dexport

coronavirus covid-19

turbosquid

$29

Covid Collection

...quid

royalty free 3d model covid collection for download as on turbosquid: 3d models for games, architecture, videos. (1682309)

3d_export

$5

mask covid-19

...mask covid-19

3dexport

covid-19 virus protection mask

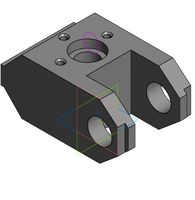

Clamp

3d_export

$11

clamp

...clamp

3dexport

clamp

3ddd

free

Clamp

... enricо zanolla , капитоне

дизайнерenrico zanollмодель clamp

3ddd

$1

Clamp

...ricо zanolla , капитоне

дизайнеры

enrico zanolla

andrea di filippo

модель clamp

dzstudio

3d_export

free

clamp

...clamp

3dexport

simple clamp model, more free 3d models here:

3d_export

$5

clamping handle

...clamping handle

3dexport

clamping handle

3ddd

$1

Clamp / DZstudio

... dzstudio , капитоне

люстра clamp от dzstudio/enrico zanolla(италия).

3ddd

$1

Светильник Clamp

...светильник clamp

3ddd

clamp

стеганый светильник clamp в двух цветах в черном и белом.

3d_export

$5

Clamp-14

...clamp-14

3dexport

3d model of clamp name 14

turbosquid

$25

Clamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$20

clamp

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.