GrabCAD

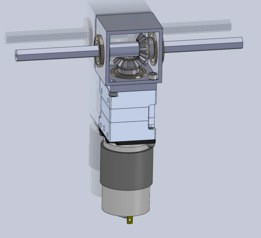

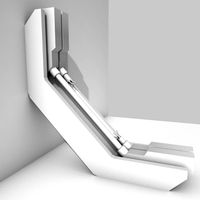

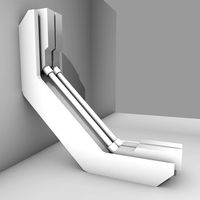

90 Degree VersaPlanatary Drive - Miter Gear Design

by GrabCAD

Last crawled date: 1 year, 10 months ago

A 90 Degree Drive for the Vexpro VersaPlanetary

4 flavors. Each use different Martin Miter Gear (each available from McMaster).

Light duty - 16T@16DP (conservative est 10:1 ratio with 775Pro input) 2X2 square tube

Medium duty 18T@12DP (conservative est 30:1 ratio with 775Pro input) 2.5X2.5 square tube (Two subflavors of this flavor THIN and THICK -- thick is stronger obviously)

Heavy duty 20T@10DP (conservative est 65:1 ratio with 775Pro input) 3X3 square tube

Note Conservative Estimates are probably 2/3 of true value (can probably use 1.5-2X safely).

Also, McMaster sells unhardened teeth, hardened teeth (which Martin makes) will give another 1.5-2X ratio

NOTE. Redesigned for Christmas! Based on building one of these, made some changes/improvements.

Fixes/updates in this re-release:

- fixed some dimensions and ticky tack problems

- simplified the housing (gave up some tilt control on the gears but based on the first sample, this is not going to be a problem) much rather have simple manufacture

- included drawings for the housing and the gear modifations (more like sketches but the info is there)

- made a thick and a thin middle version (18T12DP gear) -- That gear is a BEAST. I am surprised at how beefy it feels in your hand. I suspect that with the thick housing it will be pretty much unbreakable -- or rather it will not be the weakest link, the VP will fail first. Just a gut feel but...

- removed the covers for the largest gear version (20T10DP gear) and made the housing thicker. I am very confident that this gearbox will be stronger than the VP.

I hope you enjoy the design.

UPDATE: 2016-12-08a

Fixed a lot of ticky tacky problems. Primarily, modified length of 20T10DP gear was wrong.

Also, HARDENED TEETH, versions of Martin Gear available from Motion Industries. ~50% cost up but worth it.

-- 16T16DP 3/8" bore hardened teeth = HM1616 $37 each (vs McMaster 6529K11 $22)

-- 18T12DP 1/2" bore hardened teeth = HM1218 $48 each (vs McMaster 6529K17 $31)

-- 20T10DP 1/2" bore hardened teeth = HM1020A $61 each (vs McMaster 6529K23 $43)

Dr. Joe J.

ALSO. Native CAD files are in Solidworks -- use configurations to easily switch between design options. All the files are in a PackAndGo Zip file. JJ

UPDATE 2016-12-22:

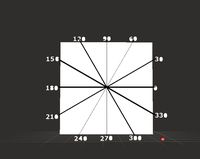

Artur pointed me to this table from Martin.

http://www.martinsprocket.com/docs/default-source/catalog-gears/miter-gears.pdf?sfvrsn=14

They have HP ratings for each miter gear. Using that I can back out a max effective ratio (recommended by Martin -- which will be pretty conservative).

Here is what I get:

ONCE AGAIN, let me stress imho these numbers are conservative for a FIRST robot but it is a good point of references and it is easy. YMMV.

Using the 10RPM numbers (effectively stall) = ~1Rad/sec

Big gear HM1020 would be 0.05HP = 37Watts = 37N-m so the max effective ratio is at 50:1 (37N-m/0.71N-m stall torque).

I get similar numbers using the 50RPM

Big gear HM1020: 0.3HP@50RPM = 223W @ 5 Rad/sec => 43N-m => max effective ratio 60:1

Mid gear HM1218. 0.02HP@10RPM = 15W @ 1 Rad/sec => 15N-m => max effective ratio 20:1

Mid gear HM1218. 0.15HP@50RPM = 112W @ 5 Rad/sec => 21N-m => max effective ratio 30:1

Little gear HM1616 0.02HP@25RPM = 15W @ 2.5 Rad/sec => 6N-m => max effective ratio 6:1

Little gear HM1616 0.04HP@25RPM = 30W @ 5 Rad/sec => 6N-m => max effective ratio 8:1

Other notes.

*** These are for if you STALL the 775Pro, not always the case.

*** These numbers use EFFECTIVE ratio not actual ratio. I would use 80-90% per stage on the VP so for example if you used (3) 5:1 ratios, you would have an actual ratio of 125:1 but an EFFECTIVE ratio of something between 70:1 and 90:1 after efficiency is accounted for.

*** AND FINALLY, let me stress AGAIN imho these numbers are conservative for a FIRST robot application.

*** The Vex 15T 12DP gear that many FRC folk are familiar with, assuming that the teeth are hardened would be able is on that Martin table as well.

HM1215 0.1HP@50RPM = 75W @ 5 Rad/sec => 14N-m => max effective ratio 20:1

4 flavors. Each use different Martin Miter Gear (each available from McMaster).

Light duty - 16T@16DP (conservative est 10:1 ratio with 775Pro input) 2X2 square tube

Medium duty 18T@12DP (conservative est 30:1 ratio with 775Pro input) 2.5X2.5 square tube (Two subflavors of this flavor THIN and THICK -- thick is stronger obviously)

Heavy duty 20T@10DP (conservative est 65:1 ratio with 775Pro input) 3X3 square tube

Note Conservative Estimates are probably 2/3 of true value (can probably use 1.5-2X safely).

Also, McMaster sells unhardened teeth, hardened teeth (which Martin makes) will give another 1.5-2X ratio

NOTE. Redesigned for Christmas! Based on building one of these, made some changes/improvements.

Fixes/updates in this re-release:

- fixed some dimensions and ticky tack problems

- simplified the housing (gave up some tilt control on the gears but based on the first sample, this is not going to be a problem) much rather have simple manufacture

- included drawings for the housing and the gear modifations (more like sketches but the info is there)

- made a thick and a thin middle version (18T12DP gear) -- That gear is a BEAST. I am surprised at how beefy it feels in your hand. I suspect that with the thick housing it will be pretty much unbreakable -- or rather it will not be the weakest link, the VP will fail first. Just a gut feel but...

- removed the covers for the largest gear version (20T10DP gear) and made the housing thicker. I am very confident that this gearbox will be stronger than the VP.

I hope you enjoy the design.

UPDATE: 2016-12-08a

Fixed a lot of ticky tacky problems. Primarily, modified length of 20T10DP gear was wrong.

Also, HARDENED TEETH, versions of Martin Gear available from Motion Industries. ~50% cost up but worth it.

-- 16T16DP 3/8" bore hardened teeth = HM1616 $37 each (vs McMaster 6529K11 $22)

-- 18T12DP 1/2" bore hardened teeth = HM1218 $48 each (vs McMaster 6529K17 $31)

-- 20T10DP 1/2" bore hardened teeth = HM1020A $61 each (vs McMaster 6529K23 $43)

Dr. Joe J.

ALSO. Native CAD files are in Solidworks -- use configurations to easily switch between design options. All the files are in a PackAndGo Zip file. JJ

UPDATE 2016-12-22:

Artur pointed me to this table from Martin.

http://www.martinsprocket.com/docs/default-source/catalog-gears/miter-gears.pdf?sfvrsn=14

They have HP ratings for each miter gear. Using that I can back out a max effective ratio (recommended by Martin -- which will be pretty conservative).

Here is what I get:

ONCE AGAIN, let me stress imho these numbers are conservative for a FIRST robot but it is a good point of references and it is easy. YMMV.

Using the 10RPM numbers (effectively stall) = ~1Rad/sec

Big gear HM1020 would be 0.05HP = 37Watts = 37N-m so the max effective ratio is at 50:1 (37N-m/0.71N-m stall torque).

I get similar numbers using the 50RPM

Big gear HM1020: 0.3HP@50RPM = 223W @ 5 Rad/sec => 43N-m => max effective ratio 60:1

Mid gear HM1218. 0.02HP@10RPM = 15W @ 1 Rad/sec => 15N-m => max effective ratio 20:1

Mid gear HM1218. 0.15HP@50RPM = 112W @ 5 Rad/sec => 21N-m => max effective ratio 30:1

Little gear HM1616 0.02HP@25RPM = 15W @ 2.5 Rad/sec => 6N-m => max effective ratio 6:1

Little gear HM1616 0.04HP@25RPM = 30W @ 5 Rad/sec => 6N-m => max effective ratio 8:1

Other notes.

*** These are for if you STALL the 775Pro, not always the case.

*** These numbers use EFFECTIVE ratio not actual ratio. I would use 80-90% per stage on the VP so for example if you used (3) 5:1 ratios, you would have an actual ratio of 125:1 but an EFFECTIVE ratio of something between 70:1 and 90:1 after efficiency is accounted for.

*** AND FINALLY, let me stress AGAIN imho these numbers are conservative for a FIRST robot application.

*** The Vex 15T 12DP gear that many FRC folk are familiar with, assuming that the teeth are hardened would be able is on that Martin table as well.

HM1215 0.1HP@50RPM = 75W @ 5 Rad/sec => 14N-m => max effective ratio 20:1

Similar models

grabcad

free

Miter Gear

...h and diametral pitches, and a 1:1 ratio. other boston gear stock bevel gears sets are available with ratios from 1-1/2:1 to 6:1.

grabcad

free

Shifting 775Pro VP

...pro vp

grabcad

pneumatic shifting 775pro + vp gearbox. 1:1 or 3:1

kind of a work in progress. but i think the concept is sound.

grabcad

free

Request: Bevel Gear/Pinion 31.75 Diametral Pitch

...ular

ø 20.0000 deg pressure angle

ø 92.0000 deg shaft angle

mg 0.4500 ratio, 1:x

pinion number of teeth 9

gear number of teeth 20

grabcad

free

Worm Gearbox

...on which the worm wheel with 15 teeth is connected. generally the number of teeth in worm wheel is the gear ratio in this system.

grabcad

free

NX9 Parametric Bevel Gear Attempt

...lowing expressions;

a - shaft angle

n1 - number of teeth on gear 1

n2 - number of teeth on gear 2

m - module

b - tooth thickness

grabcad

free

Spur gear reducer

...esigned for parameters:

- transferred power of 23 kw

- angular velocity on the input shaft 195 rad per sec

- gear ratio value 2.5

3dwarehouse

free

8 inch miter gear

...8 inch miter gear

3dwarehouse

8 inch diameter miter gear with 1/4 inch bore 9/16' thick 24 teeth #gear #gears #miter #parts

3dwarehouse

free

Hardened Precision Steel Shaft 1/4' OD, 6' Length

...shaft 1/4' od, 6' length mcmaster part number: 6061k11 #contraptor #linear #linear_motion #mcmaster #mcmastercarr #motion

grabcad

free

Gearbox - Two stage

...25

n° of teeth gear 04 = 100

ratio = 4 :1.

total ratio = 15:1 .

for more information contact me :

ach.mohamedamine@gmail.com

grabcad

free

Worm Gears

...rm gears

grabcad

module : 1

worm threads : 1

number of teeth : 60

backlash : 0.1mm

contact ratio : 1.882

pressure angle : 20 deg

Miter

3d_export

$40

Coping Saw 3D Model

...coping saw 3d model 3dexport coping saw handsaw cut miter woodworking metalworking blade tool gauge handheld teeth hand carpentry...

3ddd

$1

minka group P5211-615B

...in extension: 6 in weight: 3.31 in shade finish: miterd / white inside shade material: glass shade qty:...

3ddd

$1

minka group P127-615B

...height: 13.25in weight: 12.13in height adjustable: 1 shade finish: miterd/white inside shade material: glass shade qty:...

3ddd

$1

minka group P128-615B

...in length: 39.25 in height adjustable: 1 shade finish: miterd / white inside shade material: glass shade qty:...

3ddd

$1

RH MACHINTO

...and waxed for a warm patina built with precisely miterd frames 1 adjustable shelf per section 3 english-dovetailed drawers...

3d_export

$39

jkamleshcentertablecentertabletexture

...images are render outputs - the system unit is [miter ] - the images were rendered with v-ray 3.40.01...

3d_export

$10

vaccine bottle

...images are render outputs - the system unit is [miter - the images were rendered with v-ray 3.40.01 >>>...

3d_export

$99

3d floor plan

...images are render outputs - the system unit is [miter - the images were rendered with v-ray 3.40.01 >>>...

3d_export

$99

living room interior

...images are render outputs - the system unit is [miter - the images were rendered with v-ray 3.40.01 >>>...

3d_export

$99

house with architecture drawing sheet

...images are render outputs - the system unit is [miter - the images were rendered with v-ray 3.40.01 >>>...

Degree

design_connected

$13

Degree

...degree

designconnected

kristalia degree computer generated 3d model. designed by norguet, patrick.

3ddd

$1

Kristalia Degree

... kristalia , круглый

http://degree.kristalia.it/

turbosquid

$2

Degree Brace 4

...el degree brace 4 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205705)

turbosquid

$1

Degree Brace 3

...el degree brace 3 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205719)

turbosquid

$1

Degree Brace 2

...el degree brace 2 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205714)

turbosquid

$1

Degree Brace 1

...el degree brace 1 for download as 3ds, max, obj, c4d, and fbx on turbosquid: 3d models for games, architecture, videos. (1205710)

design_connected

$13

30 Degrees Pendant L

...30 degrees pendant l

designconnected

hay 30 degrees pendant l computer generated 3d model. designed by van hengel, johan.

turbosquid

free

30 degrees Tridimensional grid

...free 3d model 30 degrees tridimensional grid for download as on turbosquid: 3d models for games, architecture, videos. (1383401)

turbosquid

$1

90 degree 10inch elbow pipe

...ee 3d model 90 degree 10inch elbow pipe for download as sldpr on turbosquid: 3d models for games, architecture, videos. (1602274)

turbosquid

$5

90 Degree Rail Road Track

...l 90 degree rail road track for download as png, tga, and dae on turbosquid: 3d models for games, architecture, videos. (1209226)

Drive

3d_export

$10

cycloidal drive

...cycloidal drive

3dexport

cycloidal drive

3d_ocean

$5

Flash Drive

...h drive included : – materials – scene ( lighs / room ) – .c4d + .obj for any questions please feel free to contact me thank you.

3d_ocean

$5

Usb drive

...s shaders and a lighting setup. it also has a small animation of it going in and out. i saved it out as both a .blend file and...

3d_ocean

$5

Pen Drive

...est computer drive game model good low poly new pen pen drive textured unwrapped uv very low poly

a very beautiful low poly model

3d_ocean

$10

External hard drive

... is a detailed model of a trekstor external hard drive. you can easily modify the label on the top. simply edit the text objects.

turbosquid

$1

Flash Drive

...quid

royalty free 3d model flash drive for download as blend on turbosquid: 3d models for games, architecture, videos. (1231573)

turbosquid

$10

Flash Drive

...id

royalty free 3d model usb flash drive for download as obj on turbosquid: 3d models for games, architecture, videos. (1325282)

turbosquid

$1

USB Drive

...

royalty free 3d model usb drive for download as obj and fbx on turbosquid: 3d models for games, architecture, videos. (1701787)

3d_ocean

$4

USB Flash Drive

...usb flash drive

3docean

computer disk drive electronic flash mac memory pc pen usb

usb flash drive. the cartridge form

turbosquid

$49

Flash Drive

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

90

3ddd

$1

Душевая кабина 90*90*220

... domani-spa , domani

фирма domani-spa модель кабины elegance high 90*90*220

3ddd

free

Life 90-90-50

...life 90-90-50

3ddd

life , пуф

автор модели: aeroslon

3ddd

$1

Free_Gold Mosaic 90 x 90 cm

...free_gold mosaic 90 x 90 cm

3ddd

мозаика

gold mosaic tile. dimmensions 90 x 90 cm

design_connected

$11

90° armchair

...90° armchair

designconnected

l'abbate 90° armchair computer generated 3d model. designed by for use.

3d_export

$35

T-90 - tank

...t-90 - tank

3dexport

t-90 tank + texture

3ddd

$1

AQUANET Мадонна 90

...aquanet мадонна 90

3ddd

aquanet

aquanet мадонна 90

3d_export

$5

t-90 russian

...t-90 russian

3dexport

the t-90 is a russian main battle tank

3ddd

$1

neopoliscasa GS.CHD.MUno.90

...neopoliscasa gs.chd.muno.90

3ddd

neopoliscasa , комод

neopoliscasa gs.chd.muno.90 комод

3ddd

$1

горка 90-е

...горка 90-е

3ddd

горка или стенка из 90-х. 1950х2500х460

3ddd

$1

antoniolupi GRAFFIO 90

...pi graffio 90

3ddd

antoniolupi , graffio

умывальник antoniolupi graffio 90

(l90x50pxh12)

Gear

3d_ocean

$4

Gears

...gears

3docean

gear gears iron

4 different size of gears

3d_export

$5

gear

...gear

3dexport

gear

3d_export

free

Gears

...gears

3dexport

gears

3d_export

$5

gear

...gear

3dexport

a simple model of gear

3d_export

$5

gear

...gear

3dexport

gear for transmission , case machine

3d_ocean

$3

Gears

...nical parts process steampunk vehicle wheel work

10 different gear models volume 01-10 files: .3ds .c4d .obj note: you need vray

3d_ocean

$1

Spur Gear

...spur gear

3docean

decoration gear

a typical spur gear

3d_ocean

$4

Gear wheels

...gear wheels

3docean

engine engineering gear gears industry machinery mechanical toothwheel wheel

pair of gear wheels : animated.

turbosquid

$2

Gears

...rs

turbosquid

royalty free 3d model gears for download as ma on turbosquid: 3d models for games, architecture, videos. (1166710)

3d_export

$5

helical gear

...helical gear

3dexport

helical gear

Design

3ddd

$1

LINE DESIGN (Doors Design)

...line design (doors design)

3ddd

дверь

modern doors design - line design concept

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

кресло ver design

3ddd

$1

VER DESIGN

...ver design

3ddd

ver design

диван ver design

3ddd

$1

Bagno design

...bagno design

3ddd

bagno design , унитаз

санитария bagno design

3ddd

free

VER DESIGN

...ver design

3ddd

ver design , стеллаж

полка ver design

3ddd

$1

VER DESIGN

...ver design , лежак , шезлонг

шезлонг ver design

3d_export

free

designer

..., trees and much more. the model has 3 types of parts: - 4 cells - 6 cells - 8 cells the *.max file contains 5 colored materials.

3d_export

$19

level design

...level design

3dexport

you can use this design (level design) in your own game.

3d_export

$7

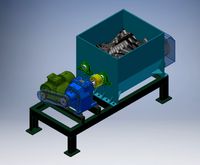

Crusher design

...crusher design

3dexport

crusher design

3d_export

$4

interior design

...interior design

3dexport

interior design