Thingiverse

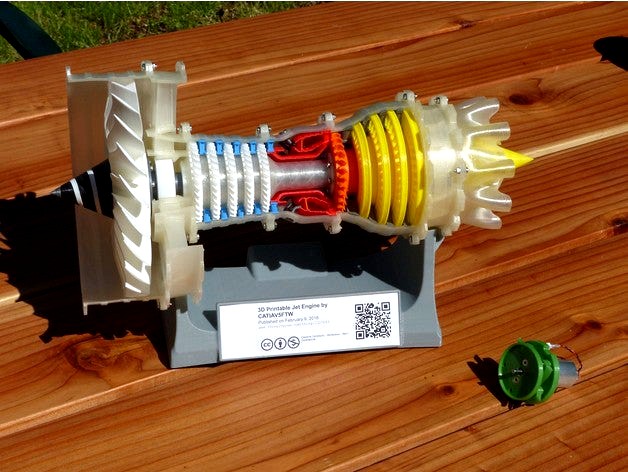

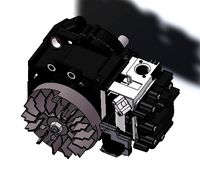

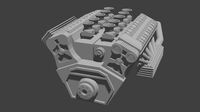

3D Printable Jet Engine, motorized by Rolumix

by Thingiverse

Last crawled date: 3 years ago

This is a remix of the excellent 3D Printable Jet Engine by CATIAV5FTW.

I modified various parts to incorporate an electric motor, to animate this wonderful model.

Print time of the set: 190 h 30 minutes. About 1,5 kg PLA

Stay tuned with the details evolution by checking the Watch box.

You will have probably noticed, this is a remix of the work of CATIAV5FTW for which I have the greatest respect, being well placed to know the amount of modeling work that it cost him.

This is why you will not find here all the STL files of this model, but only those that I have modified. You will have to download the files of the original object deposited by CATIAV5FTW and especially read the indications that he was kind enough to write. Also note that the STEP file of the complete assembly modified by me is available among the files that I have deposited which will allow those who wish to modify parts in turn and generate new STL files.

Regards and good 3D prints

06/07/2017

Optimization of "Coupleur_Moteur-arbre basse pression_V3".

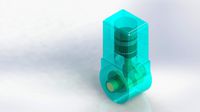

This set of 2 parts provides the connection between the electric motor and the low pressure shaft of the model.

It allows a slight misalignment of the electric motor

When the engine is stopped, it allows the low-pressure compressor to spin

(People are curious and will turn the turbine by hand if you have your back turned)

Without driving the geared motor, which is not necessarily reversible with a low torque.

06/09/2017

The "coupleur_moteurV3" printed with PLA does not have the desired endurance yet.

I reprinted it with the Colorfabb XT-CF20 and the result looks better.

So I will test a 3mm V4 extension, with PLA to see if things

always move in the right direction. I want to avoid the obligation to use something other than PLA for this part that gives me a hard time.

It is also necessary to use PLA of very high quality, otherwise it breaks.

06/29/2017

The model came back from the Paris Air Show. It operated autonomously (on batteries) more than 10 hours per day, for 7 days. 2 x 9V batteries ensure a minimum of 25 hours of operation at 1Hz. With all the batteries a minimum of 100 hours operating is OK.

For the show, I installed a coupler V1, the model being in showcase and the V4 couplers not having the reliability that seemed to me necessary.

07/21/2017

Addition of the wiring diagram.

Example of suitable engines:https://www.pololu.com/product/1585/specshttps://www.pololu.com/product/1584

This one is also suitable: Pololu item #: 1583

27/10/2017

At the request of OLGA_M, I divided the stand in two parts Left and Right to print on a smaller 3D printer.

STL and STEP files provided.

Supports needed.

A recess has been made to facilitate the alignment of the parts for assembly by gluing.

A pedido de OLGA_M, dividí el soporte en dos para imprimir en una impresora 3D más pequeña.

Archivos STL y STEP proporcionados.

Apoyos necesarios.

Se ha realizado un rebaje para facilitar la alineación de las piezas para el ensamblaje mediante encolado.

20/11/2017

To answer Olga's question about the two sets of axial clearance, I added a sectional view with arrows indicating their location. The thickness of these shims depends on the accuracy of your prints and must be adjusted accordingly. In the best case, they will not be necessary

Para responder la pregunta de Olga sobre los dos juegos de juego axial, agregué una vista en sección con flechas que indicaban su ubicación. El espesor de estas calzas depende de la precisión de sus impresiones y debe ajustarse en consecuencia. En el mejor de los casos, no serán necesarios.

28/11/2017

Hola Olga

La parte marcada con 1 es el eje de salida del motorreductor de su elección.

Las otras partes son hardware estándar. No son piezas impresas.

Como son tornillos mecánicos, es necesario tocar los orificios que los reciben.

Atentamente

Hello Olga

The part marked 1 is the output shaft of the geared motor of your choice.

The other parts are standard hardware. They are not printed parts.

As they are mechanical screws, it is necessary to tap the holes that receive them.

Best regards

15/12/2017

Hola Olga

Simplemente usado "Coupleur_Moteur-arbre_BP_V1_Slic3r"

Esta es una pieza de "fusible" que se romperá si alguien intenta girar la turbina a mano o detiene el compresor de baja presión mientras el motor está funcionando. Proporcione una o dos piezas de repuesto para reparar en caso de exposición pública.

Por mi parte, la turbina está bajo una campana transparente cuando la expongo.

Hello Olga

Simply used "Coupleur_Moteur-arbre_BP_V1_Slic3r"

This is a "fuse" part that will break if someone tries to spin the turbine by hand or stop the low pressure compressor while the engine is running. So provide one or two spare parts to repair in case of public exposure.

For my part, the turbine is under transparent bell when I expose it.

Best regards

02/20/2018

Added the data sheets of the electrical components used and their sources.

I modified various parts to incorporate an electric motor, to animate this wonderful model.

Print time of the set: 190 h 30 minutes. About 1,5 kg PLA

Stay tuned with the details evolution by checking the Watch box.

You will have probably noticed, this is a remix of the work of CATIAV5FTW for which I have the greatest respect, being well placed to know the amount of modeling work that it cost him.

This is why you will not find here all the STL files of this model, but only those that I have modified. You will have to download the files of the original object deposited by CATIAV5FTW and especially read the indications that he was kind enough to write. Also note that the STEP file of the complete assembly modified by me is available among the files that I have deposited which will allow those who wish to modify parts in turn and generate new STL files.

Regards and good 3D prints

06/07/2017

Optimization of "Coupleur_Moteur-arbre basse pression_V3".

This set of 2 parts provides the connection between the electric motor and the low pressure shaft of the model.

It allows a slight misalignment of the electric motor

When the engine is stopped, it allows the low-pressure compressor to spin

(People are curious and will turn the turbine by hand if you have your back turned)

Without driving the geared motor, which is not necessarily reversible with a low torque.

06/09/2017

The "coupleur_moteurV3" printed with PLA does not have the desired endurance yet.

I reprinted it with the Colorfabb XT-CF20 and the result looks better.

So I will test a 3mm V4 extension, with PLA to see if things

always move in the right direction. I want to avoid the obligation to use something other than PLA for this part that gives me a hard time.

It is also necessary to use PLA of very high quality, otherwise it breaks.

06/29/2017

The model came back from the Paris Air Show. It operated autonomously (on batteries) more than 10 hours per day, for 7 days. 2 x 9V batteries ensure a minimum of 25 hours of operation at 1Hz. With all the batteries a minimum of 100 hours operating is OK.

For the show, I installed a coupler V1, the model being in showcase and the V4 couplers not having the reliability that seemed to me necessary.

07/21/2017

Addition of the wiring diagram.

Example of suitable engines:https://www.pololu.com/product/1585/specshttps://www.pololu.com/product/1584

This one is also suitable: Pololu item #: 1583

27/10/2017

At the request of OLGA_M, I divided the stand in two parts Left and Right to print on a smaller 3D printer.

STL and STEP files provided.

Supports needed.

A recess has been made to facilitate the alignment of the parts for assembly by gluing.

A pedido de OLGA_M, dividí el soporte en dos para imprimir en una impresora 3D más pequeña.

Archivos STL y STEP proporcionados.

Apoyos necesarios.

Se ha realizado un rebaje para facilitar la alineación de las piezas para el ensamblaje mediante encolado.

20/11/2017

To answer Olga's question about the two sets of axial clearance, I added a sectional view with arrows indicating their location. The thickness of these shims depends on the accuracy of your prints and must be adjusted accordingly. In the best case, they will not be necessary

Para responder la pregunta de Olga sobre los dos juegos de juego axial, agregué una vista en sección con flechas que indicaban su ubicación. El espesor de estas calzas depende de la precisión de sus impresiones y debe ajustarse en consecuencia. En el mejor de los casos, no serán necesarios.

28/11/2017

Hola Olga

La parte marcada con 1 es el eje de salida del motorreductor de su elección.

Las otras partes son hardware estándar. No son piezas impresas.

Como son tornillos mecánicos, es necesario tocar los orificios que los reciben.

Atentamente

Hello Olga

The part marked 1 is the output shaft of the geared motor of your choice.

The other parts are standard hardware. They are not printed parts.

As they are mechanical screws, it is necessary to tap the holes that receive them.

Best regards

15/12/2017

Hola Olga

Simplemente usado "Coupleur_Moteur-arbre_BP_V1_Slic3r"

Esta es una pieza de "fusible" que se romperá si alguien intenta girar la turbina a mano o detiene el compresor de baja presión mientras el motor está funcionando. Proporcione una o dos piezas de repuesto para reparar en caso de exposición pública.

Por mi parte, la turbina está bajo una campana transparente cuando la expongo.

Hello Olga

Simply used "Coupleur_Moteur-arbre_BP_V1_Slic3r"

This is a "fuse" part that will break if someone tries to spin the turbine by hand or stop the low pressure compressor while the engine is running. So provide one or two spare parts to repair in case of public exposure.

For my part, the turbine is under transparent bell when I expose it.

Best regards

02/20/2018

Added the data sheets of the electrical components used and their sources.

Similar models

thingiverse

free

Taurus Bapi 850 mixer axis join by Nitemare

...or donde mismo se saca la pieza (es muy fácil) para introducir la pieza en el eje golpeando con alguna madera o martillo de goma.

thingiverse

free

e2s by TinyWorld

...as tipo "e" (conductoras).

colocar el muelle antes de ensamblar las partes.

pendiente de normalizar los elementos.

thingiverse

free

Hydroelectric turbine Generator by neoprenox

...pacidad conectado a la manguera de la ducha pero con al menos 1 bar de presión es funcional.

ire actualizando esta información...

thingiverse

free

CamionBot 6fc5dc2d98e01cc933958cc16e68c710 Piezas by prgarcie

...nte.

en la parte de abajo de la base están encajados los motores de rotación continua y el sensor infrarrojos para seguir líneas.

grabcad

free

![Turbina eolica [Wind turbine]](/t/5515460.jpg)

Turbina eolica [Wind turbine]

... los alabes. diseñada con parámetros de ingeniería y formulas empíricas. las piezas se descargan en "link de descarga".

thingiverse

free

CamionBot 6fc5dc2d98e01cc933958cc16e68c710 by prgarcie

...ecto y poder detectar fallos de diseño antes de imprimir las piezas, sobretodo a la hora de encajar los componentes electrónicos.

thingiverse

free

Save Parties Kit by ArielWalls

... bic.

la fabricación se recomienda en filamento abs con una impresora que cuente con cama caliente.

salva la fiesta como un bufón

thingiverse

free

Protector brazos Nazgul5 by ROCSMPR

...pletar el juego para los cuatro brazos del dron, es necesario imprimir dos piezas y sus respectivas simétricas (cuatro en total)

thingiverse

free

farola

...tales, se puede usar laminas de acetato.

el modelo "corona" y "pico" no es necesario imprimirlo, es opcional.

grabcad

free

Turbina Pelton_pelton turbine

...eriferia, las cuales están especialmente realizadas para convertir la energía de un chorro de agua que incide sobre las cucharas.

Rolumix

thingiverse

free

Pencil pot, female body style Voronoi by Rolumix

...pencil pot, female body style voronoi by rolumix

thingiverse

pencil pot, made from female body style voronoi version 4

thingiverse

free

PLA_Temperature_Test_180°C-225°C by Rolumix

...100 mm high, 30x30 in xy on the first 10 mm and then 20x20 on the next 90 mm.

it is also convenient as a dimensional test in xyz.

thingiverse

free

Front spool holder for Prusa i3 MK2 by Rolumix

...ttoyeur de filament. optimiation du clipsage sur le portique.

added a filament cleaner guide. snap fit optimisation on the frame.

thingiverse

free

Tour test_V2_ PET-G / ABS / ASA_215-260°C by Rolumix

...100 mm high, 30x30 in xy on the first 10 mm and then 20x20 on the next 90 mm.

it is also convenient as a dimensional test in xyz.

thingiverse

free

Jet Engine Motorized Stand 60% size by jimacid

...is a remix of the motorized stand made by rolumix his design was made for the 100% version of...

Jet

turbosquid

$1

jet

...jet

turbosquid

royalty free 3d model jet for download as fbx on turbosquid: 3d models for games, architecture, videos. (1659892)

3ddd

free

water jet

...water jet

3ddd

фонтан

water jet fountain

turbosquid

$65

JETS

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

Jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$10

jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$4

jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$1

Jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

Jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

free

jet

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

Motorized

archibase_planet

free

Motor

...base planet

motor motor engine engine electric motor

motor wagner n250213 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n151112 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

archibase_planet

free

Motor

...motor

archibase planet

motor motor engine engine

motor n150615 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

turbosquid

$15

Motor

...otor

turbosquid

royalty free 3d model motor for download as on turbosquid: 3d models for games, architecture, videos. (1639404)

3d_ocean

$5

Electric motor

...electric motor

3docean

car electric engine industry motor phase train vehicle

an electric motor enjoy!

3d_ocean

$18

Electric Motor

...electric motor

3docean

electric motor engine machine mover parts

3d model electric motor for hoist crane

turbosquid

$29

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

turbosquid

$5

Motor

... available on turbo squid, the world's leading provider of digital 3d models for visualization, films, television, and games.

3d_export

$5

electric motor

...electric motor

3dexport

electric motor use for industrial purposes

3d_export

$5

servo motor

...tor

3dexport

it's a simple part of servo motor 0.75kw for used in machines assembly to show specified motor in own project.

Printable

turbosquid

$5

printable giraffe

...uid

royalty free 3d model printable giraffe for download as on turbosquid: 3d models for games, architecture, videos. (1504825)

turbosquid

$49

Longhorn Printable

...

royalty free 3d model longhorn printable for download as stl on turbosquid: 3d models for games, architecture, videos. (1712930)

3d_export

$2

printable audi car

...printable audi car

3dexport

printable audi car

turbosquid

$40

Fox printable

...lty free 3d model fox printable for download as blend and stl on turbosquid: 3d models for games, architecture, videos. (1507558)

turbosquid

$23

Printable Statue

...ty free 3d model printable statue for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1415137)

turbosquid

$3

Ear Printable

...yalty free 3d model ear printable for download as obj and stl on turbosquid: 3d models for games, architecture, videos. (1671689)

turbosquid

$1

heart printable

...y free 3d model heart printable for download as stl and sldpr on turbosquid: 3d models for games, architecture, videos. (1209566)

turbosquid

$1

Printable Hook

...

royalty free 3d model 3d printable hook for download as stl on turbosquid: 3d models for games, architecture, videos. (1413683)

turbosquid

$30

Printable support

... model 3d printable support for download as max, 3ds, and stl on turbosquid: 3d models for games, architecture, videos. (1689342)

turbosquid

$24

Printable Dolphin

...el printable dolphin for download as , dae, fbx, obj, and stl on turbosquid: 3d models for games, architecture, videos. (1602353)

Engine

3d_export

$5

engine

...engine

3dexport

engine

3d_export

free

Engine

...engine

3dexport

engine

archibase_planet

free

Engine

...engine

archibase planet

motor engine

engine - 3d model for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

motor engine mover

engine n170708 - 3d model (*.3ds) for interior 3d visualization.

archibase_planet

free

Engine

...engine

archibase planet

engine locomotive train

locomotive - 3d model for interior 3d visualization.

turbosquid

$1

ENGINE

...osquid

royalty free 3d model ic engine for download as sldas on turbosquid: 3d models for games, architecture, videos. (1382781)

3d_export

$5

engine

...engine

3dexport

3d_export

free

engine

...engine

3dexport

turbosquid

$7

Engine

...d model animated engine mograph element3d for download as c4d on turbosquid: 3d models for games, architecture, videos. (1380716)

turbosquid

$1

ENGINE

...y free 3d model engine for download as max, 3ds, stl, and fbx on turbosquid: 3d models for games, architecture, videos. (1673703)