Thingiverse

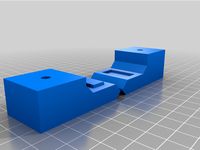

1610 CNC Optical Zeroing System by coddingtonbear

by Thingiverse

Last crawled date: 3 years, 1 month ago

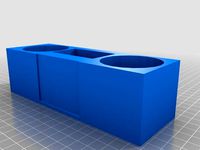

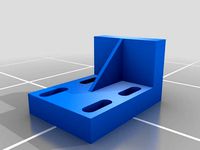

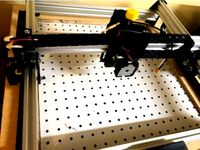

If you own a CNC mill without automatic end stops, you've probably had to restart a few jobs from the beginning because you over-ran where your end stops would've been, or you did something that set off your CNC mill's alarm. This optical alignment tool will help you get back on track from where you made your mistake rather than forcing you to start over by allowing you to manually re-zero your CNC using a cheap USB microscope you can mount to your CNC mill.

Parts Needed:

A 12mm diameter USB microscope. I bought this one for another project a while ago. and share it between that other project and this. You may be able to adapt this part to fit other microscope designs, but although the above-linked product is no longer available, there are, at present, several other identical microscopes available on Amazon:

https://www.amazon.com/Koolertorn-Microscope-Adjustable-Collections-Inspection/dp/B01FZ0FNA6/ref=sr_1_21?s=electronics&ie=UTF8&qid=1504669228&sr=1-21&keywords=USB+microscope

https://www.amazon.com/Microscope-MixMart-Endoscope-Collections-Inspection/dp/B01L6L80Q2/ref=sr_1_35?s=electronics&ie=UTF8&qid=1504669280&sr=1-35&keywords=USB+microscope

https://www.amazon.com/Microscope-1600x1200HD-Endoscope-Collections-Inspection/dp/B06XHHJ1SS/ref=sr_1_39?s=electronics&ie=UTF8&qid=1504669280&sr=1-39&keywords=USB+microscope

https://www.amazon.com/Andonstar-10-300x-Microscope-ImagingOptical-resolution/dp/B071WK7QCC/ref=sr_1_63?s=electronics&ie=UTF8&qid=1504669298&sr=1-63&keywords=USB+microscope

(Optional) 2x M5 Roll-in spring T-nuts. These are used for securing your target in a stable position. They are not strictly necessary -- the part might be snug enough in its design to not be too-easily moved, but if you do not use these, I recommend holding the target arm in place using a little bit of tape. If you do go the spring t-nut route, you probably don't need to screw them in using a bolt as you've seen me do in the above photos; the spring is probably more than enough tension to prevent anything from moving around.

Software allowing you render crosshairs on your webcam's image. This is something that both bCNC and Chilipeppr can do with minimal effort.

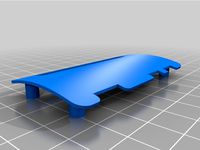

After printing the target arm, you will want to either draw a target onto the top of the arm, or print, cut out and tape or glue on a gridded target like I've done.

Use Instructions:

Before beginning your print job, zero your CNC such that your camera's crosshairs are exactly aligned with the target image.

Machine your thing. If a problem occurs causing your CNC to become un-zero'd, move your CNC back to the zero position by moving to the point at which your camera's crosshairs line up with the target image as they did in step #1.

Parts Needed:

A 12mm diameter USB microscope. I bought this one for another project a while ago. and share it between that other project and this. You may be able to adapt this part to fit other microscope designs, but although the above-linked product is no longer available, there are, at present, several other identical microscopes available on Amazon:

https://www.amazon.com/Koolertorn-Microscope-Adjustable-Collections-Inspection/dp/B01FZ0FNA6/ref=sr_1_21?s=electronics&ie=UTF8&qid=1504669228&sr=1-21&keywords=USB+microscope

https://www.amazon.com/Microscope-MixMart-Endoscope-Collections-Inspection/dp/B01L6L80Q2/ref=sr_1_35?s=electronics&ie=UTF8&qid=1504669280&sr=1-35&keywords=USB+microscope

https://www.amazon.com/Microscope-1600x1200HD-Endoscope-Collections-Inspection/dp/B06XHHJ1SS/ref=sr_1_39?s=electronics&ie=UTF8&qid=1504669280&sr=1-39&keywords=USB+microscope

https://www.amazon.com/Andonstar-10-300x-Microscope-ImagingOptical-resolution/dp/B071WK7QCC/ref=sr_1_63?s=electronics&ie=UTF8&qid=1504669298&sr=1-63&keywords=USB+microscope

(Optional) 2x M5 Roll-in spring T-nuts. These are used for securing your target in a stable position. They are not strictly necessary -- the part might be snug enough in its design to not be too-easily moved, but if you do not use these, I recommend holding the target arm in place using a little bit of tape. If you do go the spring t-nut route, you probably don't need to screw them in using a bolt as you've seen me do in the above photos; the spring is probably more than enough tension to prevent anything from moving around.

Software allowing you render crosshairs on your webcam's image. This is something that both bCNC and Chilipeppr can do with minimal effort.

After printing the target arm, you will want to either draw a target onto the top of the arm, or print, cut out and tape or glue on a gridded target like I've done.

Use Instructions:

Before beginning your print job, zero your CNC such that your camera's crosshairs are exactly aligned with the target image.

Machine your thing. If a problem occurs causing your CNC to become un-zero'd, move your CNC back to the zero position by moving to the point at which your camera's crosshairs line up with the target image as they did in step #1.

Similar models

thingiverse

free

MacBook Pro with Retina Display Vertical Dock by TomExplorador

...er/dp/b008ala6dw/ref=sr_1_3?s=electronics&ie=utf8&qid=1517752168&sr=1-3&keywords=macbook+ethernet+adapter+thunder

thingiverse

free

Rgb Light Strip Lamp by Ratakis

...lament-dimensional-accuracy/dp/b00mb3cv6k/ref=sr_1_1?ie=utf8&qid=1524145120&sr=8-1&keywords=clear+pla+filament+1.75mm

thingiverse

free

gMax, 80/20 frame parts for mods, hacks, and addons by Spudwheelie

...pport-terminal-rocker-toggle-switch/dp/b00zwwyucu/ref=sr_1_15?ie=utf8&qid=1464391427&sr=8-15&keywords=switch+spst#ask

thingiverse

free

Speaker box by Ratakis

...-4ft/dp/b01kstsv76/ref=sr_1_1_sspa?s=electronics&ie=utf8&qid=1521518432&sr=1-1-spons&keywords=aux+cable&psc=1

thingiverse

free

3D Printable 3D Printer by TheJadeRabbit

...r_1_4?ie=utf8&qid=1530916900&sr=8-4&keywords=3d+printer+hotend

code(marlin): https://github.com/marlinfirmware/marlin

thingiverse

free

Laser DL-44 by Dinoman217

...tubing-eventronic/dp/b072pcq2lw/ref=sr_1_5?s=industrial&ie=utf8&qid=1527956002&sr=1-5&keywords=heat+shrink+tubing

thingiverse

free

The Cube Mini Fridge by thewatchmakerfl

...ref=sr_1_2?ie=utf8&qid=1436833279&sr=8-2&keywords=potentiometer&pebp=1436833322445&perid=0pmtmyyyy6vn4mzst3fx

thingiverse

free

Mini desk fan by Creborg319

....com/6300rpm-shaft-magnetic-motor-hobby/dp/b00bg61s44/ref=sr_1_5?ie=utf8&qid=1533705112&sr=8-5&keywords=mini+dc+motor

thingiverse

free

Rack for HD Salcar and Hub USB Orico by SilverMoon

...%c2%ae-alluminio-porte-adattatore-12v2-5a/dp/b01ef108jw/ref=sr_1_12?ie=utf8&qid=1485760283&sr=8-12&keywords=orico+usb

thingiverse

free

DIY Flashlight Housing. Build List Noted by RyanM283

...you don't overdrain your battery:https://www.amazon.com/bayite-digital-voltmeter-display-motorcycle/dp/b00yaluxh0/ref=sr_1_3?ie=utf8&qid=1521947055&sr=8-3&keywords=voltage+display someone else's diy with similar setup video:...

Coddingtonbear

thingiverse

free

Amprobe PM51A Stand by coddingtonbear

...m51a stand by coddingtonbear

thingiverse

this is a simple stand for an amprobe pm51a multimeter. this might also fit the pm55a.

thingiverse

free

Syringe Cap (Luer lock) by coddingtonbear

...syringes so i can apply it to boards without making a huge mess. these caps are designed to seal the container while not in use.

thingiverse

free

GoPro Handlebar Mount (M6 / Captive nut) by coddingtonbear

...nbear

thingiverse

this is a simple gopro mount i designed for my bike secured using two captive m6 nuts and two m6 socket bolts.

thingiverse

free

Wall Switch Lockout by coddingtonbear

...g the clasp to the plate) that, when closed, prevents the switch it is attached to from being switched from its current position.

thingiverse

free

16x2 LCD Stand with Button by coddingtonbear

...hile it rests atop its toaster oven. for the button, i'm using a cheap 16mm momentary push button like this one on amazon.

thingiverse

free

VESA Mount Stand Adapter by coddingtonbear

...th of 1/2in wooden dowel rod for propping your screen on its side.

the screen shown in the photo above is a spectre e205w-16003r.

thingiverse

free

Topeak Handlebar Mount GoPro Adapter by coddingtonbear

...really only use that bag when bike touring, why not use the clip as a mount for my gopro when i'm commuting to and from work?

thingiverse

free

NVBDL+ Mounting Clips for CNC by coddingtonbear

...r to the back of your cnc machine.

note that you'll need to print two copies of the attached stl, but one should be mirrored.

thingiverse

free

Joist GoPro Mount by coddingtonbear

...ns about how to configure your print to automatically pause at the right moments for you to insert each nut.

four 20mm+ m6 bolts.

thingiverse

free

Dremel Drill Press 12mm Microscope Mount by coddingtonbear

...r dremel drill press.

an 'arm' that connects your microscope to the base, aiming roughly at the drill press's target.

1610

thingiverse

free

China CNC 1610 Holddown Clamp by goulien

...c 1610 holddown clamp by goulien

thingiverse

china cnc 1610 holddown clamp

a small clamp to use with my chinese 1610 cnc router.

thingiverse

free

Technics 1210 cover on 1610 mount by dr_welt

...chnics 1610 or similar with broken cover.

for the famous 1210 the cover is pretty easy to get. use this to mount it on your 1610.

thingiverse

free

Pen for china cnc 1610 by WerMRolenT

...nt

thingiverse

hi all! spread stl file attachments for nc in 1610.

it will take one or two long bolts. also, two or two springs.

thingiverse

free

Dremel flexible tool adapter for CNC 1610 by Ultralisk2005

...tralisk2005

thingiverse

this item is needed to replace 755 motor in cnc 1610 machine. (44.5 mm) with dremel flexeble tool (20mm)

thingiverse

free

China CNC 1610 by Schlumpfi2411

... by schlumpfi2411

thingiverse

ps. hat es dir gefallen? kannst mich auch unterstützen wenn du willst.

paypal: www.paypal.me/tfenk

thingiverse

free

CNC 1610 Hold Down Clamp

...ded strength. i machined the pivot from brass for additional rigidity and strength and used brass threaded inserts for the knobs.

thingiverse

free

Suporte PCB para CNC 1610 3810 e outras by dinizhobby

...para cnc 1610 3810 e outras by dinizhobby

thingiverse

suporte pcb (placa de circuito impresso) para em cnc 1610 3018 e outras.

thingiverse

free

1610 CNC Clamp by Jlbis1

...wo base options:

base short: should work for material up to 8mm

base tall: should work for material up to 16mm

happy printing :)

thingiverse

free

patch for 1610 CNC 55mm Spindle Mount by WhiteHare

... cnc 55mm spindle mount by whitehare

thingiverse

14mm patch for coddingtonbear model: https://www.thingiverse.com/thing:2817974

thingiverse

free

1610 router woodpecker board enclosure by underthetire

...the woodpecker board with a little protection. 40mm fan should snap in. there is a 12vdc plug on the board to plug the fan in to.

Optical

thingiverse

free

Optical connector holder for optical table by BobyTheGreat

...holder to screw on an optical bench. really useful for optical cable management in a lab. it works with the adafc3 from thorlabs.

thingiverse

free

Optic for Boltgun

...optic for boltgun

thingiverse

optic for gw plastik boltgun mark iii und mark iv

thingiverse

free

Optical Endstop by CruiseLee

...optical endstop by cruiselee

thingiverse

optical endstop

thingiverse

free

1'' optic adapter for 15mm filter/optic by docphoton

...lter/optic by docphoton

thingiverse

here used to hold a 15mm optic (a line filter) in a 1'' standard optics table mount.

thingiverse

free

Optic Experiment by mmzay

...thingiverse this project is learn the focus of lenses. optical experiments...

thingiverse

free

optic gaming lithophane by judemloza

...optic gaming lithophane by judemloza

thingiverse

optic gameing

thingiverse

free

Optical illusion by FP-Creator

...optical illusion by fp-creator

thingiverse

optical illusion

thingiverse

free

Optical drive holder by AlhimikSG

...optical drive holder by alhimiksg

thingiverse

optical drive holder

thingiverse

free

OpTic Gaming Logo by Dylpooh

...optic gaming logo by dylpooh

thingiverse

the optic gaming logo.

thingiverse

free

Basic Optical illusion by Defauld

...basic optical illusion by defauld

thingiverse

a basic optical illusion. ^^

Zeroing

thingiverse

free

Zero by smight

...zero by smight

thingiverse

zero

thingiverse

free

zero

...zero

thingiverse

and another beyblade part

thingiverse

free

RackPI - Raspberry Pi zero/zero W

...ckpi - raspberry pi zero/zero w

thingiverse

rack support for raspberry pi zero / zero w and oled screen 28x32 0.91 "ssd1306

thingiverse

free

sub zero by SavageWarlord

...sub zero by savagewarlord

thingiverse

sub zero

by sub zero 314http://www.123dapp.com/creature/sub-zero/5829557

thingiverse

free

case for "raspberry pi zero/zero w" with "Camera Module for Raspberry Pi Zero" by atsushi_kbt

...ducts/raspberry-pi-zero-w

camera module for raspberry pi zero

https://shop.pimoroni.com/products/raspberry-pi-zero-camera-module

thingiverse

free

Rasberry Pi zero / Zero W/ Pi Zero WH case by CoreDesign

...designed this case for the rasberry pi zero wh. pretty minimalistic. you can fit it by snapping the top part onto the bottom part

thingiverse

free

Zero Two stencil

...zero two stencil

thingiverse

zero two stencil

thingiverse

free

Zero Cam mount

...zero cam mount

thingiverse

zero cam mount

thingiverse

free

Zero helmet by mansonkibe

...zero helmet by mansonkibe

thingiverse

zero helmet. printed with supports.

thingiverse

free

ZERO KEYRING by shire

...zero keyring by shire

thingiverse

zero bike logo, think these are electric bikes

Cnc

thingiverse

free

CNC by Robi1602

...cnc by robi1602

thingiverse

cnc

thingiverse

free

CNC Feet - Nikodem CNC

...ixe-it, and they are a big hole for screw the aluminium profile (on the pictures).

enjoy and thanks nikodem for you amazing cnc !

thingiverse

free

CNC Case

...cnc case

thingiverse

control box to be used with rs-cnc or any other cnc you like.

thingiverse

free

Susferus CNC

...susferus cnc

thingiverse

susferus cnc testing

thingiverse

free

RS-CNC , the new model of R-CNC by RoMaker

...new model of r-cnc by romaker

thingiverse

the rs-cnc is the replacement of the r-cnc (https://www.thingiverse.com/thing:2159840)

thingiverse

free

Fixture- CNC by sidd200970

...fixture- cnc by sidd200970

thingiverse

cnc machine vise for diy cnc machines

thingiverse

free

Cnc Lazer by baymikro

...cnc lazer by baymikro

thingiverse

cnc lazer

thingiverse

free

CNC dusthood by Idegraaf

...cnc dusthood by idegraaf

thingiverse

dusthood for cnc

thingiverse

free

coupling cnc by poggia10

...coupling cnc by poggia10

thingiverse

coupling cnc

thingiverse

free

cnc square by MR_MUSTARD

...cnc square by mr_mustard

thingiverse

square for cnc

System

thingiverse

free

Coordinate system

...coordinate system

thingiverse

coordinate system

thingiverse

free

ACRO SYSTEMS DRAG CHAIN SYSTEM by dragonfire81m

...acro systems drag chain system by dragonfire81m

thingiverse

chain link mounting system for acro system openbuilds

thingiverse

free

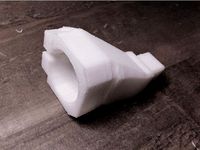

Circulatory System

...circulatory system

thingiverse

made in a 3d design software

designed for students

circulatory system based on images

thingiverse

free

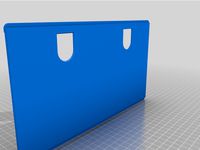

Clutch system

...clutch system

thingiverse

clutch system inspired from lego technics kit

print with default settings

thingiverse

free

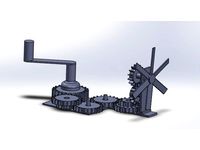

Gear system test-Systeme d'engrenage Test by CPS007

...gear system test-systeme d'engrenage test by cps007

thingiverse

gear system test-systeme d'engrenage test

13cm7cm7cm

thingiverse

free

Pulley System by LeapFrog_3D

...pulley system by leapfrog_3d

thingiverse

pulley system

thingiverse

free

System Block by CryoShift

...system block by cryoshift

thingiverse

system block

thingiverse

free

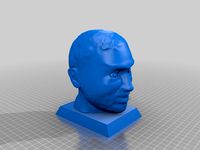

System administrator by Diodmag

...system administrator by diodmag

thingiverse

system administrator, sculpting

thingiverse

free

L.A. Systems by Bjorn175

...l.a. systems by bjorn175

thingiverse

l.a. systems mold

thingiverse

free

Decken Montage-system

...decken montage-system

thingiverse

decken montage-system