Cults

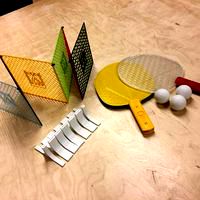

PING & PONG tables

by Cults

Last crawled date: 6 years, 1 month ago

PING & PONG tables

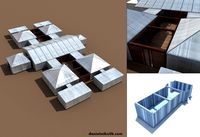

Here is my proposal for the superb challenge offered by CULTS 3D on the theme of 3D furniture printing. #DAGOCULTS

Do not hesitate to vote for me to help me win the trophy. Just click on "I LOVE" at the top right of the presentation photo of my project (no account of any kind !!!) These challenges stimulate my creativity and I want to develop 3D printing and to propose you new projects by winning one of the two beautiful printers DAGOMA in play.

I describe below my approach of design to propose to you this unique model, special creation for the event.

3D printing offers many advantages, such as easy customization of its designs (choice of colors and materials for printed parts), sharing, making available the digital data necessary for their manufacture by others, and also the ability to modulate their size simply for serial effects or nesting elements.

I like to make many objects for a very long time and practiced woodwork since my beginnings. 3D printing was added two years ago to my palette of tools and is day after day a valuable ally; in this same spirit "FabLab and Makers" I regularly use the laser cutter.

The theme of the coffee tables quickly became the most exposed object when guests are welcomed, and become the media for the rapid diffusion of new technologies.

The mechanical resistance of the parts manufactured by the FDM printers (especially on the Z-axis, which offers a small fragility on all the machines) has guided my design research, wishing to offer the subscribers of the CULTS 3D platform a perfectly functional model . The design of the parts is such that the aluminum tubes reinforce the Z-axis, making them very solid and suitable for the use of this technology for furniture.

I wanted to make in DIY these low table legs whose design is trendy because I did not find them already realized or at very high prices. The choice of standard aluminum tubes (diameters 10 mm -> PING, 8 mm -> PONG) arranged in this way (triangulation) allows good mechanical strength. They are good value for money and available in several finishes (raw, anodized in several colors). It is possible to choose beech trunnions, steel tubes or threaded rods for an industrial design look. I put the .stl files available for a 12 mm diameter, for other characteristics of tubes, it is enough to do a scaling either in meshlab or meshmixer for example (I use for my part netfabb), or in your favorite slicer.

The plots of the templates that helped me to cut the trays (format .dxf or .pdf) as well as a tutorial to obtain perfect shapes using a router and a copier are in. zip files to download. Contact me via the CULTS 3D platform if you want more information.

Finally the top tray can be of the material and shape you want. Here, I chose printed parts in gray elephant, natural anodized aluminum tubes and Hevea trays (thickness 33 mm for the top plate and 18 mm for the other).

Supplies needed to complete the project (for both tables):

- 2 trays of your choice (For example, an ellipse of 820 x 520 mm in 33 mm and an ellipse of 540 x 420 mm in 18 mm / glued laminated hevea).

- 8 tubes of 432.5 mm in diameter 10 mm. For my part, I cut them with a mini cup rotary plumbing tube, it works very well: very precise cut, no fatigue nor noise, aluminum chips / internet link:

https://www.leroymerlin.fr/ v3 / p / products / pipe cutter-diam-3-28-mm-e1500561352

- 4 tubes of 430,5mm in diameter 10mm.

- 3 or 4 bases 10mm and 3 or 4 feet 10 mm printed in PLA for example color to your convenience. That is to say 75 m of filament in 1.75 mm.

- 16 screws 30mm long, 3.5mm diameter.

- 8 tubes of 335 mm in diameter 8 mm.

- 4 tubes of 330 mm in diameter 8 mm.

- 3 or 4 bases 8 mm and 3 or 4 feet 8mm printed in PLA for example color to your convenience. That is 45 m of filament in 1.75 mm.

- 16 screws 18 mm long, 3.5 mm diameter.

- Two-component glue, unless the holes of the printed parts are well adjusted, which should be the case if the printing parameters below are respected.

DIY, personalize, and have fun ;-)

#DAGOCULTS

Do not hesitate to vote for me to help me win the trophy. Just click on "I LOVE" at the top right of the photo of my project. These challenges stimulate my creativity and I want to develop two beautiful DAGOMA printers in play.

.

of series or nested elements.

I like to make many objects for a very long time and practiced woodworking since my beginnings. 3D printing was added two years ago to my palette of tools and is day after day a valuable ally; in this same spirit "FabLab and Makers" I regularly use the laser cutter.

.

. The design of the parts is the Z-axis, making them very solid and suitable for the use of this technology for furniture.

The choice of standard aluminum tubes (diameters 10 mm -> PING, 8 mm -> PONG) allows in this way (triangulation) allows good mechanical strength. They are good value for money and available in several finishes (raw, anodized in several colors). It is possible to choose beech trunnions, steel tubes or threaded rods for an industrial design look. I put the .stl files available for a 12 mm diameter, for other characteristics of tubes, it is enough to do a scaling either in meshlab or meshmixer for example, or in your favorite slicer.

. Contact me via the CULTS 3D platform if you want more information.

. Here, I thing printed in a gray elephant, natural anodized aluminum tubes and Hevea trays (thickness 33 mm for the top plate and 18 mm for the other).

).

- 8 tubes of 432.5 mm in. For my part, I cut them with a mini cup rotary plumbing tube, this work very well: very precise cut, no fatigue nor noise, aluminum chips / internet link:

https://www.leroymerlin.fr/v3/p/ products / pipe-cutter-diam-3-28-mm-e1500561352

- 4 tubes of 430,5mm in diameter 10mm.

- 3 or 4 bases 10mm and 3 or 4 feet 10 mm printed in PLA for example color to your convenience. That is to say 75 m of filament in 1.75 mm.

- 16 screws 30mm long, 3.5mm in diameter.

- 8 tubes of 335 mm in.

- 4 tubes of 330 mm in.

- 3 or 4 bases 8 mm and 3 or 4 feet 8mm printed in PLA for example color at your convenience. That is 45 m of filament in 1.75 mm.

- 16 screws 18 mm long, 3.5 mm diameter.

- Two-component glue, unless the holes of the printed parts are well adjusted.

DIY, personalize, and have fun ;-)

Here is my proposal for the superb challenge offered by CULTS 3D on the theme of 3D furniture printing. #DAGOCULTS

Do not hesitate to vote for me to help me win the trophy. Just click on "I LOVE" at the top right of the presentation photo of my project (no account of any kind !!!) These challenges stimulate my creativity and I want to develop 3D printing and to propose you new projects by winning one of the two beautiful printers DAGOMA in play.

I describe below my approach of design to propose to you this unique model, special creation for the event.

3D printing offers many advantages, such as easy customization of its designs (choice of colors and materials for printed parts), sharing, making available the digital data necessary for their manufacture by others, and also the ability to modulate their size simply for serial effects or nesting elements.

I like to make many objects for a very long time and practiced woodwork since my beginnings. 3D printing was added two years ago to my palette of tools and is day after day a valuable ally; in this same spirit "FabLab and Makers" I regularly use the laser cutter.

The theme of the coffee tables quickly became the most exposed object when guests are welcomed, and become the media for the rapid diffusion of new technologies.

The mechanical resistance of the parts manufactured by the FDM printers (especially on the Z-axis, which offers a small fragility on all the machines) has guided my design research, wishing to offer the subscribers of the CULTS 3D platform a perfectly functional model . The design of the parts is such that the aluminum tubes reinforce the Z-axis, making them very solid and suitable for the use of this technology for furniture.

I wanted to make in DIY these low table legs whose design is trendy because I did not find them already realized or at very high prices. The choice of standard aluminum tubes (diameters 10 mm -> PING, 8 mm -> PONG) arranged in this way (triangulation) allows good mechanical strength. They are good value for money and available in several finishes (raw, anodized in several colors). It is possible to choose beech trunnions, steel tubes or threaded rods for an industrial design look. I put the .stl files available for a 12 mm diameter, for other characteristics of tubes, it is enough to do a scaling either in meshlab or meshmixer for example (I use for my part netfabb), or in your favorite slicer.

The plots of the templates that helped me to cut the trays (format .dxf or .pdf) as well as a tutorial to obtain perfect shapes using a router and a copier are in. zip files to download. Contact me via the CULTS 3D platform if you want more information.

Finally the top tray can be of the material and shape you want. Here, I chose printed parts in gray elephant, natural anodized aluminum tubes and Hevea trays (thickness 33 mm for the top plate and 18 mm for the other).

Supplies needed to complete the project (for both tables):

- 2 trays of your choice (For example, an ellipse of 820 x 520 mm in 33 mm and an ellipse of 540 x 420 mm in 18 mm / glued laminated hevea).

- 8 tubes of 432.5 mm in diameter 10 mm. For my part, I cut them with a mini cup rotary plumbing tube, it works very well: very precise cut, no fatigue nor noise, aluminum chips / internet link:

https://www.leroymerlin.fr/ v3 / p / products / pipe cutter-diam-3-28-mm-e1500561352

- 4 tubes of 430,5mm in diameter 10mm.

- 3 or 4 bases 10mm and 3 or 4 feet 10 mm printed in PLA for example color to your convenience. That is to say 75 m of filament in 1.75 mm.

- 16 screws 30mm long, 3.5mm diameter.

- 8 tubes of 335 mm in diameter 8 mm.

- 4 tubes of 330 mm in diameter 8 mm.

- 3 or 4 bases 8 mm and 3 or 4 feet 8mm printed in PLA for example color to your convenience. That is 45 m of filament in 1.75 mm.

- 16 screws 18 mm long, 3.5 mm diameter.

- Two-component glue, unless the holes of the printed parts are well adjusted, which should be the case if the printing parameters below are respected.

DIY, personalize, and have fun ;-)

#DAGOCULTS

Do not hesitate to vote for me to help me win the trophy. Just click on "I LOVE" at the top right of the photo of my project. These challenges stimulate my creativity and I want to develop two beautiful DAGOMA printers in play.

.

of series or nested elements.

I like to make many objects for a very long time and practiced woodworking since my beginnings. 3D printing was added two years ago to my palette of tools and is day after day a valuable ally; in this same spirit "FabLab and Makers" I regularly use the laser cutter.

.

. The design of the parts is the Z-axis, making them very solid and suitable for the use of this technology for furniture.

The choice of standard aluminum tubes (diameters 10 mm -> PING, 8 mm -> PONG) allows in this way (triangulation) allows good mechanical strength. They are good value for money and available in several finishes (raw, anodized in several colors). It is possible to choose beech trunnions, steel tubes or threaded rods for an industrial design look. I put the .stl files available for a 12 mm diameter, for other characteristics of tubes, it is enough to do a scaling either in meshlab or meshmixer for example, or in your favorite slicer.

. Contact me via the CULTS 3D platform if you want more information.

. Here, I thing printed in a gray elephant, natural anodized aluminum tubes and Hevea trays (thickness 33 mm for the top plate and 18 mm for the other).

).

- 8 tubes of 432.5 mm in. For my part, I cut them with a mini cup rotary plumbing tube, this work very well: very precise cut, no fatigue nor noise, aluminum chips / internet link:

https://www.leroymerlin.fr/v3/p/ products / pipe-cutter-diam-3-28-mm-e1500561352

- 4 tubes of 430,5mm in diameter 10mm.

- 3 or 4 bases 10mm and 3 or 4 feet 10 mm printed in PLA for example color to your convenience. That is to say 75 m of filament in 1.75 mm.

- 16 screws 30mm long, 3.5mm in diameter.

- 8 tubes of 335 mm in.

- 4 tubes of 330 mm in.

- 3 or 4 bases 8 mm and 3 or 4 feet 8mm printed in PLA for example color at your convenience. That is 45 m of filament in 1.75 mm.

- 16 screws 18 mm long, 3.5 mm diameter.

- Two-component glue, unless the holes of the printed parts are well adjusted.

DIY, personalize, and have fun ;-)

Similar models

thingiverse

free

PTFE tube miter box / Cutter

...and there are no leaks in the extruder.

for 4 mm. external diameter tube (1.75 mm filament)

to cut the tube, use a normal cutter.

cults

free

Ping Pong table tennis

...ping pong table tennis

cults

ping pong table tennis full printable 3d print model

full printable ping pong games

grabcad

free

Ping Pong Trophy

...uminum and steel. the handle is longer than normal because it slid into an aluminum base but the paddle part itself is accurate.

thingiverse

free

Ping Pong Ball by hannaholshevski

...ping pong ball by hannaholshevski

thingiverse

using the eggbot, i printed my name with stars on a ping pong ball.

grabcad

free

SCUTTLE ping pong turret

...scuttle ping pong turret

grabcad

ping pong turret i designed to be mounted on 2020 aluminum extrusion mount

thingiverse

free

Bolt for "Rod and Tube Cutter for Dremel" by Kando_G

...3 mm, in the print 2.8 mm so you can use a metric m3 screw.

i also uploaded the files from the creator, which i used for my bolt.

cults

free

Bracket

...bracket

cults

bracket for screw diameter 4 mm

x: 10.3 cm

y: 2.5 cm

z: 10.3

bracket for screw diameter 4 mm

#dagocults

thingiverse

free

Anti kink part for 13/10 (3/8") tubes by Serachja

...to prevent 13/10 mm tubes from kinking. i'm using it in my watercooled system, works quite nice.

they are very easy to print.

thingiverse

free

Inspirational Ping Pong balls by snigdhapaka

...lls. that way, if you are losing a ping pong match, you can just take a second to read the ping pong ball and boost your spirit=)

cults

free

Big bracket

...big bracket

cults

bracket for screw diameter 4 mm

x: 10.3 cm

y: 2.5 cm

z: 15 cm

bracket for screw diameter 4 mm

#dagocults

Ebenisterie

3dwarehouse

free

Coffre de rangement

...pas l'inclure dans un travail en cours. #bois #coffre #ebenisterie #menuiserie #meuble #wood...

3dwarehouse

free

jeux en bois- Sapo

...la bouche du sapo (crapeau en espagnol). #ancien #bois #ebenisterie #frog #grenouille #jeu #jeux #menuiserie #play #rana #sapo...

3dwarehouse

free

Myriam Racat Ebenisterie

...myriam racat ebenisterie

3dwarehouse

cabinet maker house

3dwarehouse

free

Table bureau Louis XIII

...superieur d'ebenisterie d'avignon esea #13 #antiquité #bureau #chene #chêne #ebenisterie #epoque #esea #louis #moderne #style #table #xiii #ébénisterie...

3dwarehouse

free

Ebenisterie

...ebenisterie

3dwarehouse

3dwarehouse

free

Ebenisterie Table avec Tiroir

...warehouse

table réalisée en merisier à l'été 2011 à st cézaire sur siagne 06530 #bureau #ebenisterie #menuiserie #table_bois

3dwarehouse

free

Table à écrire et à jeux Louis XVI

...l'ecole superieur d'ebenisterie d'avignon esea #16 #antiquité #bureau #damier #ebenisterie #echiquier #epoque #esea #frisage #gainé #gainés #jeux #louis #merisier...

Trundle

3ddd

free

Catalina Bed & Trundle с розовым бельем

... односпальная

catalina bed & trundle с розовым бельем,текстуры в комплекте,материалы настроены.

3ddd

$1

Catalina Bed & Trundle

... кантри , односпальная

catalina bed & trundle кровать одноместная в стиле кантри

3d_export

$22

Child Bedroom Colorful 3D Model

...child kid young drawer window curtain screen colorful whimsical trundle textures materials desktop computer monitor keyboard vray child bedroom...

3d_export

$12

bed kinder

...bed kinder 3dexport baby cot "princess daybed w / trundlequot; 1079w x 2032l x 1314h (mm)<br>for work, please remove...

turbosquid

free

Trundle Bed

...bosquid

royalty free 3d model trundle bed for download as ma on turbosquid: 3d models for games, architecture, videos. (1236527)

3d_sky

free

Catalina Bed Trundle & with pink linen

...amp; with pink linen

3dsky

bed single country

catalina bed trundle & with pink linen texture, complete, customized materials.

thingiverse

free

Trundle Bed Post Caps

...trundle bed post caps

thingiverse

this is a simple cover for the sharp posts that are on the top corners of our trundle bed

thingiverse

free

Microwave Trundle by raydebs

...hese in your microwave. i printed in pla, and it hasn't melted yet, but if it does, i'll print a replacement with nylon.

thingiverse

free

Thicker Select Mini Glass Bed Spacer by khackbarth

...and have additional space between the bed and the "trundle?)" to put cork insulation in. the work i did...

thingiverse

free

Munitionsschlepper by bigwig_mark

...create a munitionsschlepper (ammunition carrier). i wanted one to trundle behind the bison. scaled to 1/100 created with...

Dagocults

cults

free

Tubes4shelves v1.0

...to fasten the board with the tube, and voila! #dagocults ...

cults

free

EASIT printable chair!

...and must be printed a second time in symmetry. #dagocults ...

cults

$1

office

...office cults furniture office pc office for pc #dagocults ...

cults

free

Wine cellar

...wine cellar cults cellar at wine bottles fridge #dagocults wine cellar for 9 bottles. we all need a...

cults

free

Foerris Chest

...at the extruder. support are used in the corners. #dagocults ...

cults

free

Architect dream chair #DAGOCULTS

...ng to give me filament ???

happy to promote your filament on youtube or facebook, instagram whatever you like....

anyone???

cults

free

Case roller shutter

...roller shutter cults rouleau obturateur aveugle cuisine le magasin #dagocults i'm developed and design roller shutter system - fitted...

cults

$2

Deer Lamp

...now participating in the 3d printed furniture design competition #dagocults ...

cults

free

KIKO! Folding three-leg stool customizable to the inifini

...stool can have its place in your interior decoration. #dagocults 09/10/17 update of the error correction...

cults

free

Key holder Camera

...camera cults gun key ring camera goal sigma gadget dagocults telephoto never will dagoma here is a small 3d...

Cofee

3d_export

$5

Coffee Cup 3D Model

...reak 3dmodel 3d model vray corona

coffee cup 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl alarti 113418 3dexport

cg_studio

$10

Coffee table bizzotto3d model

...n poly modeling

.max .obj .fbx - coffee table bizzotto 3d model, royalty free license available, instant download after purchase.

cg_studio

$7

Coffee table BELLONI3d model

...ly modeling

.max .obj .fbx .3ds - coffee table belloni 3d model, royalty free license available, instant download after purchase.

3ddd

$1

Cofee table - Natalie

...cofee table - natalie

3ddd

журнальный

в сцене присутствует только модель столика с текстурами.

размеры 120х60х45см

3ddd

$1

Modern Cofe Table

...modern cofe table

3ddd

журнальный

modern cofe table

3d_ocean

$4

Coffee Cup

...coffee cup 3docean cofee cup coffee cup 3d...

3d_ocean

$4

Coffee Cup Large

...coffee cup large 3docean cofee cup drinks kitchen milkshake mug table tea very detailed...

3d_ocean

$15

Coffee Bean for Particle Systems 3Ds max

...particle systems 3ds max 3docean 3ds animated bean beans cofee coffe coffee drink hot lowpoly max particle particles systems...

3d_ocean

$30

Nursery room furniture 06 Set

...furniture 06 set include 3d models: bed, table, chair, cofee table, nightstand, dresser, mirror, bookcase. room environment...

3ddd

$1

Prism cofe

...prism cofe

3ddd

кофейный , сервиз

кофейный набор prism cofe.

Pong

3d_export

$19

Ping Pong Rackets Balls 3D Model

...et ball balls ping pong play sport equipment collection photorealistic

ping pong rackets balls 3d model humster3d 69821 3dexport

3ddd

$1

Butterfly cassio case

...ракетки , настольный теннис , table tennis , ping pong , butterfly , cassio butterfly cassio case, max...

3d_ocean

$15

arkanoid game set

...3docean arcade arcanoid ball brick game game object ping pong pong includes animation of exploding brick. just make a...

cg_studio

$75

Ping Pong Table3d model

... model

cgstudio

.3ds .max .obj .wrl - ping pong table 3d model, royalty free license available, instant download after purchase.

3d_export

$15

Ping Pong Paddle 3D Model

...port table tennis 3d models

ping pong paddle 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl flavia 113174 3dexport

cg_studio

$12

Ping Pong Tennis Table3d model

...o

tennis ping pong table

.dwg - ping pong tennis table 3d model, royalty free license available, instant download after purchase.

cg_studio

$19

Ping Pong Rackets & Balls3d model

...fbx .lwo .max .mb .obj - ping pong rackets & balls 3d model, royalty free license available, instant download after purchase.

archibase_planet

free

Table

...archibase planet table ping-pong table table tennis table ping pong n190214 - 3d model (*.gsm+*.3ds) for interior 3d...

3ddd

$1

Butterfly table tennis racket

...table tennis racket 3ddd racket bat table tennis ping pong butterfly timo b , теннис , ракетка eng: close-up,...

humster3d

$15

3D model of Ping Pong Rackets & Balls

...d model of ping pong rackets & balls in various file formats. all our 3d models were created maximally close to the original.

Ping

3d_export

$19

Ping Pong Rackets Balls 3D Model

...et ball balls ping pong play sport equipment collection photorealistic

ping pong rackets balls 3d model humster3d 69821 3dexport

3ddd

$1

Butterfly cassio case

...для ракетки , настольный теннис , table tennis , ping pong , butterfly , cassio butterfly cassio case, max...

3d_ocean

$15

arkanoid game set

...set 3docean arcade arcanoid ball brick game game object ping pong pong includes animation of exploding brick. just make...

3d_ocean

$4

Chinese Historically Authentic Vase

...same urn vase vessel water-glass chinese historically authentic vase mei-ping vase. celadon porcelain, with inlaid design. yi period. g.m....

3ddd

$1

Ширма giorgetti Ping

... ширма , giorgetti ping

ширма giorgetti ping 175х173/348х4

cg_studio

$75

Ping Pong Table3d model

... model

cgstudio

.3ds .max .obj .wrl - ping pong table 3d model, royalty free license available, instant download after purchase.

3d_export

$15

Ping Pong Paddle 3D Model

...port table tennis 3d models

ping pong paddle 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl flavia 113174 3dexport

cg_studio

$12

Ping Pong Tennis Table3d model

...o

tennis ping pong table

.dwg - ping pong tennis table 3d model, royalty free license available, instant download after purchase.

cg_studio

$19

Ping Pong Rackets & Balls3d model

...fbx .lwo .max .mb .obj - ping pong rackets & balls 3d model, royalty free license available, instant download after purchase.

archibase_planet

free

Table

...table archibase planet table ping-pong table table tennis table ping pong n190214 - 3d model (*.gsm+*.3ds) for interior 3d...

Trio

3ddd

$1

3D Панель Трио

...3d панель трио 3ddd панель http://mzgi.ru/3d-panel/trio ...

3ddd

$1

Succulent Rock Trio Planters in White

...succulent rock trio planters in white

3ddd

hello everyone

this is new my model , the flower succulent

3ddd

$1

Светильники "DESIGN Stockholm HOUSE"

...and base cover, aluminium arm, steel base insert; - "trio vases " three vases with different shapes. hand-made glass....

archive3d

free

Lamp 3D Model

...lamp 3d model archive3d trio lamp - raut - 3d model for interior 3d...

3ddd

$1

TRIO

...trio

3ddd

trio

потолочный люстра trio

Ø:55cm.

3ddd

$1

Chair trio-oak-stoo

...chair trio-oak-stoo

3ddd

табурет

chair trio-oak-stoo

www.dpstudio3d.com

3ddd

$1

Avantgarde Acoustic / TRIO CLASSICO

...дель рупорной акустической системы.

сайт производителя:http://www.avantgarde-acoustic.com/trio-classico-product-en.html

3ddd

$1

Set Trio

...ddd

tobias grau , set

http://www.tobias-grau.com/shop/detail_1_0_3714_0_0.html

3d_ocean

$3

truss trio round 7

...truss trio round 7

3docean

lighting round trio truss

truss trio round 7 meters

3d_ocean

$3

truss trio 2 meters

...truss trio 2 meters

3docean

lighting trio truss

truss model 2 meters long

Duo

3ddd

$1

INCANTO Duo

... металлические подлокотники с обитыми накладками (модификация soft), металлическую раму. столешницы столиков выполнены из стекла.

3ddd

$1

Pendant Lamp Trumpet Brass Spider 5-lite

...два осветительных прибора kare 1, floor lamp trumpet brass duo материал : алюминий с порошковым покрытием , латунь полированная...

3ddd

$1

Anglepoise Duo Table Lamp

...anglepoise duo table lamp

3ddd

anglepoise duo table lamp

3ddd

$1

Набор детской мебели Sweet Baby Duo (Little Princess)

...набор детской мебели sweet baby duo (little princess)

3ddd

sweet baby duo

материалы настроены для corona renderer

3ddd

free

Набор детской мебели Sweet Baby Duo (Sea World)

...набор детской мебели sweet baby duo (sea world)

3ddd

sweet baby duo

материалы настроены для corona renderer

3d_ocean

$12

Samsung Galaxy y Duos

...es good renders model is completely in quads mental ray is used for render more details can be seen in preview images and in t...

3ddd

free

Jacob Delafon Micro Mega Duo

...18) c изогнутым экраном (art. e4910). производство: jacob delafon (франция). габариты (ш +г) 1500*1000.

материалы: акрил, стекло.

3ddd

$1

Набор детской мебели Sweet Baby Duo (Safari)

...t baby duo (safari)

3ddd

sweet baby duo , safari

материалы настроены для corona renderer

3ddd

$1

тумба «CAPRIGO», коллекция «FRESCO», ширина тумбы 1602 мм

...633 мм устанавливается: раковина 1441-540-g , раковина vidima seva duo ...

3ddd

free

Cappellini Duo

...same flower, that passes through both vessels, manifests itself as the only sincere means of connection between the two elements.

Trend

3ddd

$1

Bon Bentwood Chair

...oak cross back dining chairs that have become on trend size: h: 88cm w: 46cm d:...

3d_ocean

$15

iPhone 6 - Element3D

...6 iphone6 mobile new phone smartphone tablet touch touchscreen trend video watch iphone 6 model will be available shortly...

3d_ocean

$15

Element3D - iPhone 6S

...iphone6 iphone6s mobile new phone smartphone tablet touch touchscreen trend video watch here i present you with my new...

3ddd

$1

RIVA 1920 Natura 6

...miya company black and white cat mug set, urban trend ceramic abstract bird sculpture, phaidon books. в архиве: *.max...

3ddd

$1

Union Trend TR12

...под проем 810 мм

высота-под проем 2230 мм (hmax=2400 мм-легко редактируется)

в папке max 2012+fbx.

polys: 16216 без сглаживания.

3ddd

$1

Maisons du monde BLACKSTAGE

...декоративный набор, все предметы из maisons du monde, blackstage trend -комод trocaderomango, ref. 130151 -настенное панно hexagones, ref. 153066...

3ddd

$1

Кувшин фирмы Emsa (EMSA FLOW)

...под 3и вино, сок, и холодная вода пользуйтесь на здоровье)http://www.trendunter.com/trends/emsa-flow-carafe http://www.youtube.com/watch?v=ufmxjciibm8 ...

3ddd

free

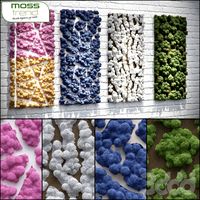

Декоративные панели от MOSS Trend

...наименование: декоративные панели с мха

изготовитель: moss trend

высота: 400мм

ширина: 400мм

глубина: 20мм

материал: мох, гипс

3ddd

$1

Union Trend TR01

...мм

высота-под проем 2230 мм (hmax=2400)

в папке max 2012+fbx+vray ral colors paint

polys:

0 iterations=7586

1 iterations=60696

3d_ocean

$18

Vogue 3 PC Purple Microfiber Sofa Set

...to anyone’s room. this sofa se is the hottest trend in the...

Template

3d_export

$19

Exhibition booth area 30X15 3DMAX2009 3D Model

...show demonstration screen advertising business expo stall exhibit display template 3d models booth design booth exhibition booth area 30x15...

3d_export

$19

Exhibition booth area 9X6 3DMAX2009 3D Model

...show demonstration screen advertising business expo stall exhibit display template 3d models booth design booth exhibition booth area 9x6...

3d_ocean

$17

20F Shipping Container

...baked oa and uv mapping, 3 sample skin, .png template and ready for games. .blend | obj | verts:...

3d_ocean

$12

Google Cardboard

...elastic glasses google kraft lens mobile mockup photorealistic product template video virtual the first 3d model of google cardboard...

3d_ocean

$10

DVD cases

...3docean case case cd cd dvd dvd electronics packaging template nice set of 3d modelled dvd cases. included are...

3d_ocean

$4

Wine Bottles with Labels

...label mock up mockup model pink red wine restaurant template white white wine wine high poly 3d model: wine...

3d_ocean

$19

Branding Template C4D

...h c4d r15 and vray. the models are also provided. included: all materials and setup for the studio: psd materials background t...

3d_ocean

$1

V-Ray Red Plastic Material

...plastic material 3docean material plastic professional red shader shiny template v-ray vray a simple red plastic material file made...

3d_ocean

$1

V-Ray Orange Plastic Material

...plastic material 3docean material orange plastic professional shader shiny template v-ray vray a simple orange plastic material file made...

3d_ocean

$1

V-Ray Green Plastic Material

...plastic material 3docean green material plastic professional shader shiny template v-ray vray a simple green plastic material file made...

Creator

3ddd

$1

J.L. Lobmeyr Illuminated Mirror

...j.l. lobmeyr illuminated mirror 3ddd lobmeyr creator j.l. lobmeyr (designer) materials and techniques: mirror, crystal, brass...

3ddd

$1

Grand 1800s Wheeler Mirrored Lamp

...wheeler , grand https://www.1stdibs.com/furniture/lighting/chandeliers-pendant-lights/grand-1800s-wheeler-mirrored-lamp/id-f_3456232/ grand 1800s wheeler mirrored lamp creator wheeler reflector company (manufacturer) of the period: industrial place...

3ddd

$1

A Pair of Unique Blue Glass and Nickel Lamps

...unique blue glass and nickel lamps price upon request creator roberto giulio rida (artist) of the period: modern country:...

3ddd

$1

Large Palwa Gilded Brass and Crystal Mirror

...gilded brass and crystal mirror 3ddd palwa , круглое creator palwa (manufacturer) in the style of: hollywood regency materials...

3d_ocean

$12

Low Poly Wild West Sheriff Office

...sheriff wild west another low poly for wild west creator. this set is designed for games which are developed...

3d_ocean

$50

3D Dungeon Pack

...and companies who dont have acess to 3d model creator or have the skill to create their own 3d...

3d_ocean

$19

Lego house

...lego house 3docean brick construction creator house lego set toy building block this is a...

3d_ocean

$39

Train Track Creator Pro

...n tracks, for video game or rendering in a matter of minutes. all the models in this pack are low poly with high resolution te...

3ddd

free

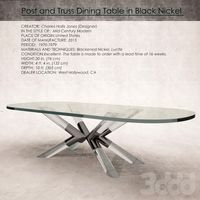

2 Dining Table + Trus Coffee Table

...dining table in black nickel by charles hollis jones creator charles hollis jones (designer) in the style of: mid-century...

3ddd

free

Venini Two Tier Textured Glass Fixture

...textured glass fixture 3ddd venini price: price upon request creator venini (manufacturer) place of origin: italy date of manufacture:...

Customizable

3d_ocean

$3

Gears 4

...gears automatic brushed car clock gear clockwork cog cogwheel customizable engine factory gear gearbox gears gearset gearwheel industrial parts...

3d_export

$59

Office 02 3D Model

...is suitable either for high-end renderings and animations easily customizable materials office 02 3d model download .c4d .max .obj...

3d_export

$79

Bedroom 60 3D Model

...is suitable either for high-end renderings and animations easily customizable bedroom 60 3d model download .c4d .max .obj .fbx...

cg_studio

$79

Event Tents v2.0 Customizable3d model

...se

.3ds .max .obj .fbx - event tents v2.0 customizable 3d model, royalty free license available, instant download after purchase.

3ddd

$1

Sofa KRAVITZ Azea

...available from 2 to 4 seats. seat: single cushion customizable size l 180 x w 80 x h 73...

3ddd

$1

Carpet Patchwork

...carpet patchwork 3ddd ковер patchwork carpet, customizable color and fabrics size: 240cm x...

3ddd

$1

Provence Luxe Round Customizable Sectional

...e , ротанг , круглый

без мусора, стёки открыты.

3d_ocean

$15

Sport Shoes

...sport shoes models - clean mesh - colors 100% customizable - scene ready with all ligths and environment -...

3d_ocean

$12

3D Customizable Puzzle Set (16x10)

...icture - mograph compatible (you can effect the pieces with mograph effectors) - included also a non-mograph version with plai...

3d_ocean

$5

Metalic Dots 3D Texture

...3d texture 3docean black brushed metal cool creative customisable customizable customize dark dark texture dots dotted easy easy to...

Diy

3ddd

$1

Fifti-fifti DIY lamps

...xform.

18 859 полигонов.

в архиве также есть файл макс 2012.http://www.fifti-fifti.net/en/catalog/take-off-light.html

3ddd

$1

Coffee table / Loft

...coffee table / loft 3ddd журнальный detailed model of diy coffee table dimensions: 1200x850x400mm topology: subdivision ready polys: 33060...

3ddd

$1

Handmade LOFT table lamp

...handmade loft table lamp 3ddd diy handmade loft table lamp формат файлов: 3dmax 2014 -...

3ddd

$1

DIY coffee table + decor

... рамка для фото

кофейный столик diy 400х350х600(h) мм. моделился по фото. внимание: материалы - corona.

3d_ocean

$30

Fokker DII Aircraft

...e remnant of the early years of the 20th century . features: - c4d (textured all channels) – 3ds (textured color only) ...

3d_ocean

$18

Caulking gun

...squeeze, apply, sealant, seal, construction, liquid nails, glue, industrial, diy tool, toolbox, building, decorating mastic sealant gun model. model...

3d_export

$8

Modern clock 3D Model

...model 3dexport modern stylish clock interior design mountains simple diy minute hour modern clock 3d model download .c4d .max...

3ddd

$1

Eco DIY Collection, Eduardo Alessi

...стольные

будильник в виде оленя,который благодаря простым инструкциям, можно легко собрать без клея или дополнительных поставок.

3ddd

$1

Industrial Kesbeke lamp

...anne kesbeke. лампа ручной работы, из категории "сделай сам" (diy. в качестве плафона, автор предлагает использовать обычную стеклянную банку,...

3d_export

$19

DIY Pig Decorative Light Lamp 3D Model

...diy pig animal

diy pig decorative light lamp 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl artdyx 104100 3dexport

Furnishing

3d_export

$200

50 Sculpture collection 3D Model 3D Model

...figurine art vray character stone figure elements decor decoration furnishing architecture model 50 sculpture collection 3d model 3d model...

3d_export

$10

SLITBAR IKEA 3D Model

...model 3dexport ikea knife couteau slitbar cuisine fourniture furniture furnishing tablewre slitbar ikea 3d model nea3de 30911...

3d_export

$8

Chair 3D Model

...3d model 3dexport sofa chair couch lounge design furniture furnishing armchair bench modern table ergonomic orthopedic bed bedroom chair...

3d_export

$5

Sofa 3D Model

...3d model 3dexport sofa chair couch lounge design furniture furnishing armchair bench modern table ergonomic orthopedic bed bedroom sofa...

3d_export

$5

Shelving 3D Model

...3d model 3dexport sofa chair couch lounge design furniture furnishing armchair bench modern table ergonomic orthopedic bed bedroom shelving...

3d_export

$5

Sofas 3D Model

...3d model 3dexport sofa chair couch lounge design furniture furnishing armchair bench modern table ergonomic orthopedic bed bedroom sofas...

3d_export

$5

Bed 3D Model

...3d model 3dexport sofa chair couch lounge design furniture furnishing armchair bench modern table ergonomic orthopedic bed bedroom bed...

3d_export

$9

Table with chairs 3D Model

...3d model 3dexport sofa chair couch lounge design furniture furnishing armchair bench modern table ergonomic orthopedic bed bedroom table...

3d_export

$9

Chair 3D Model

...3d model 3dexport sofa chair couch lounge design furniture furnishing armchair bench modern table ergonomic orthopedic bed bedroom chair...

3d_export

$5

Sofa 3D Model

...3d model 3dexport sofa chair couch lounge design furniture furnishing armchair bench modern table ergonomic orthopedic bed bedroom sofa...

Cutter

3d_export

$6

Philishave electric shaver 3D Model

...3d model 3dexport philishave shave shaving electric shaver hair cutter philishave electric shaver 3d model medesdesign 49599...

3d_export

$10

Cuticle Scissors 3D Model

...metal surgical beauty hygiene care body finger fingernail cosmetics cutter salon scissor manicure cuticle scissors 3d model firdz3d 88675...

3d_export

$20

Engagement ring 3D Model

...platinum 3d rpm stl jewel engagement ring 3d model cutter 21707...

3d_export

$99

Circular Sawing Machine TK5C-50GL 3D Model

...3d model 3dexport circular sawing machine tk5c-50gl tsune tool cutter turning mill ctx machine lathe circular sawing machine tk5c-50gl...

3ddd

$1

стильный мужской набор для бритья

...воск для усов edwin jagger, англия опасная бритва king cutter фирмы heinr. boker & co, золинген, германия целое мыло...

archive3d

free

Boat 3D Model

...boat 3d model archive3d boat cutter launch ship boat n281116 - 3d model (*.gsm+*.3ds+*.max) for...

archive3d

free

Mower 3D Model

...mower 3d model archive3d lawn mower grass-cutter dendropilot mower - 3d model for interior 3d...

3d_ocean

$12

Medical Scissors

...medical scissors 3docean cut cutter scissors tool. metal medical realistic high poly model of...

3d_ocean

$4

Pizza Cutter

...s and read description carefully before you buy. thanks. render system, materials and environment image ready for cinema 4d. t...

3d_ocean

$39

Low Poly RTS Orc Building Set

...poly mine oracle orc rts set smithy throne wood cutter wow get started on your new game prototype quickly...

Laser

3d_export

$8

SciFi Gun 2 3D Model

...3dexport weapon machine gun rifle sci-fi alien space plasma laser energy package asset pack low poly futuristic fantasy rustic...

3d_ocean

$5

Raygun - Alien Blast Pistol

...beam blaster death electroshock energy fiction fictional gun heat laser phaser pistol plasma ray raygun retro science scifi vintage...

3d_export

$6

3d panel futurism 3D Model

...grille decor gold corian modern perforated contemporary math serie laser cutting pattern panel futurism wall gate fence 3d panel...

3d_export

$6

3D Wall Panel 3D Model

...math serie cell decoration decor picture gold 3d modern laser cutting pattern contemporary wall cnc people 3d wall panel...

3d_export

$6

3d panel futurism 3D Model

...grille decor gold corian modern perforated contemporary math serie laser cutting pattern panel futurism wall gate fence 3d panel...

3d_export

$6

3D Wall Panel 3D Model

...panel serie cell decoration decor picture gold 3d modern laser cutting pattern contemporary wall cnc 3d wall panel 3d...

3d_export

$6

3D Wall Panel 3D Model

...panel serie cell decoration decor picture gold 3d modern laser cutting pattern contemporary wall cnc lips 3d wall panel...

3d_export

$6

3d wall panels Decor Picture Panel 3D Model

...3d model 3dexport panels decor 3d picture panel wall laser cutting pattern 3d wall panels decor picture panel 3d...

3d_export

$6

3d wall panels Decor Picture Panel 3D Model

...3d model 3dexport panels decor 3d picture panel wall laser cutting pattern 3d wall panels decor picture panel 3d...

3d_export

$6

3d wall panels Decor Picture Panel 3D Model

...3d model 3dexport panels decor 3d picture panel wall laser cutting pattern 3d wall panels decor picture panel 3d...

Kit

3d_ocean

$5

Streets and highways construction kit

...make city streets. roads has the pavement. models low poly and ready to use in games. texture size in render images 2048×2048,...

3d_ocean

$29

Proto Cemetery Set

...they are meant to be used as a construction kit for rapid game prototyping. the blocks are real world...

3d_export

$12

Grapes Single Fruit Bunches and Model Kit 3D Model

...

grapes single fruit bunches and model kit 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl martin3d 108952 3dexport

3d_export

$15

Drum Stand 3D Model

...holder snare rim hardware modern orchestra music band drumkit kit rack drum stand 3d model download .c4d .max .obj...

3d_export

$10

Wizard kit 3D Model

...at broom glasses spell globe

wizard kit 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl emadnabil27 109521 3dexport

3d_ocean

$35

Prototyper Desert Set

...they are meant to be used as a construction kit for rapid game prototyping. the blocks are real world...

3ddd

$1

Nomades Authentic Ceilin Lights

...decorative porcelain, glass or wooden elements - an electrification kit khaki, black or transparent, according tot the models -...

archive3d

free

Drum 3D Model

...drum 3d model archive3d drum musical instrument tambour drum kit drum conga n310116 - 3d model (*.gsm+*.3ds) for interior...

cg_studio

$30

Scifi Interior Construction Kit (Basic)3d model

...bx .dae .3ds - scifi interior construction kit (basic) 3d model, royalty free license available, instant download after purchase.

cg_studio

$25

Stockade construction kit3d model

...ds .obj .mb .max .fbx .c4d - stockade construction kit 3d model, royalty free license available, instant download after purchase.

Assembly

3d_export

$15

Ratchet Socket Wrench 3D Model

... nut torque tighten spanner screw extension hex assemble mechanic craftsman

ratchet socket wrench 3d model firdz3d 88311 3dexport

3ddd

$1

IKEA SODERHAMN

...ene, polyester hollow fibre wadding

armrest cover/ three-seat section cover:

40% polyester, 16% cotton, 40% modacrylic, 4% nylon

3d_ocean

$15

Robot

...robot 3docean 3d arm assembly factory-robot hydraulic-machine industrial-robot max mechanical model nano sci-fi worker-robot...

3d_ocean

$2

Jigsaw Puzzle

...s puzzle tiles toy

simple jigsaw puzzle model. modeled nicely in 3ds max and include mulitiple format (.obj, .max, .3ds and.fbx).

3d_export

$10

Kids tricycle 3D Model

...3d model 3dexport kids vehicle tricucle cycle bicycle 3d assembly solidworks kids tricycle 3d model download .c4d .max .obj...

3ddd

$1

IKEA SMYG

...ikea smyg

3ddd

ikea

assembled size

width: 195 mm

cord length: 250 cm

3ddd

$1

Nomades Authentic Ceilin Lights

... khaki, black or transparent, according tot the models

- the heights are adaptable and the chandeliers can be assembled together.

3ddd

$1

Встраиваемые светильники delta light 5 видов 02

...светильники delta light 5 видов 02 3ddd delta light http://www.deltalight.com/en/products/detail/imax-50-401-60-00 http://www.deltalight.com/en/products/detail/tweeter-trimless-111-206-21-11 http://www.deltalight.com/en/products/light/diro/diro-st-ok?form=searchform&reference;_nr=&location;=1&fixation;=1&assembly=2&new;=0&type;=light®ion;=int http://www.deltalight.com/en/products/light/imax/imax-wallwash?form=searchform&reference;_nr=&location;=1&fixation;=1&assembly;=2&new;=0&type;=light®ion;=int http://www.deltalight.com/en/products/detail/downforce-r-202-42-23 ...

3ddd

$1

Spider Light

...t is easy to transport, easy to assemble and had enough structural strength, but at the same time was endowed with colorful form.

3ddd

$1

Carl HansenSon CH410 Peter's Chair

...in the war years quality furniture was hard to find - so he made his own. dimensions: 42 cm (width), 32 cm (depth), 47 cm (height

Assemble

3d_export

$15

Ratchet Socket Wrench 3D Model

...ratcheting bolt nut torque tighten spanner screw extension hex assemble mechanic craftsman ratchet socket wrench 3d model firdz3d 88311...

3ddd

$1

IKEA SODERHAMN

..., плед , подушки , кушетка soderhamn one-seat section assemble size width: 93 cm depth: 99 cm height: 83...

3d_ocean

$15

Robot

...j 3ds included 1 texture maps. for bump, diffuse 1 texture use : side_colour.png (1024*1024) this model contains 110388 polygo...

3d_ocean

$2

Jigsaw Puzzle

...jigsaw puzzle 3docean assemble colorful customize texture decoration game jigsaw puzzle kids picture...

3d_export

$10

Kids tricycle 3D Model

...cycle 3d assembly solidworks

kids tricycle 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl chaoskid 105575 3dexport

3ddd

$1

IKEA SMYG

...ikea smyg 3ddd ikea assemble size width: 195 mm cord length: 250...

3ddd

$1

Nomades Authentic Ceilin Lights

...the heights are adaptable and the chandeliers can be assemble ...

3ddd

$1

Встраиваемые светильники delta light 5 видов 02

...&new;=0&type;=light®ion;=int http://www.deltalight.com/en/products/detail/downforce-r-202-42-23

3ddd

$1

Spider Light

...of material that is easy to transport, easy to assemble and had enough structural strength, but at the same...

3ddd

$1

Carl HansenSon CH410 Peter's Chair

...four pieces of wood that can be assembled and disassemble again and again - no tools are necessary. that...

Customization

3d_export

$30

Villa 209 3D Model

...st suburban architecture building residential suburbs two story vinyl siding house set

villa 209 3d model freebird 49452 3dexport

3d_export

$30

Villa 200 3D Model

...st suburban architecture building residential suburbs two story vinyl siding house set

villa 200 3d model freebird 49438 3dexport

3d_export

$30

Villa 168 3D Model

...st suburban architecture building residential suburbs two story vinyl siding house set

villa 168 3d model freebird 49405 3dexport

3d_export

$30

Villa 205 3D Model

...st suburban architecture building residential suburbs two story vinyl siding house set

villa 205 3d model freebird 49446 3dexport

3d_export

$30

Villa 158 3D Model

...st suburban architecture building residential suburbs two story vinyl siding house set

villa 158 3d model freebird 49390 3dexport

3d_export

$30

Villa 215 3D Model

...st suburban architecture building residential suburbs two story vinyl siding house set

villa 215 3d model freebird 49457 3dexport

3d_export

$30

Villa 121 3D Model

...st suburban architecture building residential suburbs two story vinyl siding house set

villa 121 3d model freebird 49357 3dexport

3d_export

$30

Villa 222 3D Model

...st suburban architecture building residential suburbs two story vinyl siding house set

villa 222 3d model freebird 49467 3dexport

3d_export

$30

Villa 242 3D Model

...st suburban architecture building residential suburbs two story vinyl siding house set

villa 242 3d model freebird 49501 3dexport

3d_export

$30

Villa 269 3D Model

...st suburban architecture building residential suburbs two story vinyl siding house set

villa 269 3d model freebird 49540 3dexport

Furniture

3d_export

$5

SHOE RACK 3D Model

...rack 3d model 3dexport shoe rack bedside table tables furniture shoe rack 3d model olga.d 90203...

3d_export

$12

Bedside Table 3D Model

...table 3d model 3dexport bed bedroom table little small furniture 3ds wood wooden room textured bedside table 3d model...

3d_export

$19

Celtic Three Drawer Storage Shelf 3D Model

...buffet hutch celtic three drawer cupboard section southern enterprises furniture locker chest drawers celtic three drawer storage shelf 3d...

3d_export

$39

Amphora Couch Red Leather 3D Model

...leather 3d model 3dexport amphora couch red leather modern furniture sofa amphora couch red leather 3d model nikolai 72589...

3d_export

$12

Chair 3D Model

...chair 3d model 3dexport armchair chair furniture architecture interior living room dining wooden seating metal design...

3d_export

$25

glass chair 3D Model

...3d model 3dexport comfortable chair lightweight plastic steel metal furniture object design glass chair 3d model ssh 7202...

3d_export

free

Download free Table TV 3D Model

...download free table tv 3d model 3dexport table tv furniture interior decor wood table tv 3d model anagor 86245...

3d_export

$10

Roche Bobois Small furniture Tenere stools 3D Model

...3dexport

roche bobois table stool small furniture desk

roche bobois small furniture tenere stools 3d model beskor 93097 3dexport

3d_export

$10

SLITBAR IKEA 3D Model

...3d model 3dexport ikea knife couteau slitbar cuisine fourniture furniture furnishings tablewre slitbar ikea 3d model nea3de 30911...

3d_export

$50

Fast Food Restaraunt Set 3D Model

...tables chair seats pan tray bottles support boxes interiors furniture fast food restaraunt set 3d model humster3d 33025...

Table

design_connected

$13

BL2 Table Lamp

...bl2 table lamp

designconnected

gubi bl2 table lamp computer generated 3d model. designed by dudley best , robert .

design_connected

$11

Beam Table Lamp

...beam table lamp

designconnected

muuto beam table lamp computer generated 3d model. designed by chung, tom.

design_connected

$13

Gravity Table Lamp

...gravity table lamp

designconnected

gubi gravity table lamp computer generated 3d model. designed by space copenhagen.

design_connected

free

Song Coffee Tables

...song coffee tables

designconnected

free 3d model of song coffee tables by minotti designed by dordoni, rodolfo.

design_connected

free

Moon Lounge Table

...moon lounge table

designconnected

free 3d model of moon lounge table by gubi designed by space copenhagen.

design_connected

free

Fuwl Cage Table

...fuwl cage table

designconnected

free 3d model of fuwl cage table by menu designed by form us with love.

design_connected

$13

Ring Coffee Tables

...ring coffee tables

designconnected

minotti ring coffee tables computer generated 3d model.

design_connected

$11

Ring Side Tables

...ring side tables

designconnected

minotti ring side tables computer generated 3d model.

design_connected

$16

Boden Small Tables

...boden small tables

designconnected

minotti boden small tables computer generated 3d model. designed by guillaumier, gordon.

design_connected

free

JWDA Table Lamp

...jwda table lamp

designconnected

free 3d model of jwda table lamp by menu designed by wagell, jonas.

Tables

design_connected

$13

BL2 Table Lamp

...bl2 table lamp

designconnected

gubi bl2 table lamp computer generated 3d model. designed by dudley best , robert .

design_connected

$11

Beam Table Lamp

...beam table lamp

designconnected

muuto beam table lamp computer generated 3d model. designed by chung, tom.

design_connected

$13

Gravity Table Lamp

...gravity table lamp

designconnected

gubi gravity table lamp computer generated 3d model. designed by space copenhagen.

design_connected

free

Song Coffee Tables

...song coffee tables

designconnected

free 3d model of song coffee tables by minotti designed by dordoni, rodolfo.

design_connected

free

Moon Lounge Table

...moon lounge table

designconnected

free 3d model of moon lounge table by gubi designed by space copenhagen.

design_connected

free

Fuwl Cage Table

...fuwl cage table

designconnected

free 3d model of fuwl cage table by menu designed by form us with love.

design_connected

$13

Ring Coffee Tables

...ring coffee tables

designconnected

minotti ring coffee tables computer generated 3d model.

design_connected

$11

Ring Side Tables

...ring side tables

designconnected

minotti ring side tables computer generated 3d model.

design_connected

$16

Boden Small Tables

...boden small tables

designconnected

minotti boden small tables computer generated 3d model. designed by guillaumier, gordon.

design_connected

free

JWDA Table Lamp

...jwda table lamp

designconnected

free 3d model of jwda table lamp by menu designed by wagell, jonas.

Amp

design_connected

$29

Outline Sectional with Chaise

...with chaise computer generated 3d model. designed by anderssen & ...

3d_export

$10

Speakers 3D Model

...speakers 3d model 3dexport speaker sound amp computer headphone speakers 3d model ailamvnn 69699...

3d_export

$5

Red Blue 3D Model

...red blue 3d model 3dexport red&amp;blue red blue chair rietveld destijl interior product design red...

3ddd

$1

Late

...late 3ddd late , danish-store , барный барный стул отсюдаhttp://www.danish-store.ru/collections/chairs/products/late?variant=890643065&nbsp; ...

3ddd

$1

Picnic Table

..., журнальный , машина manufacturer: meritalia model: fiat500_ picnic tablehttp://www.meritalia.it/fiat500/fiat500eng/fiat500.html&nbsp; ...

3ddd

$1

The UP Coffee Table

..., кофейный 45000 полигонов материалы: стекло,пластик,сталь. официальный сайтhttp://www.duffylondon.com/ цена: &#163;5,800.00 :) лимитированная серия 12...

3ddd

$1

LEMA - Ocean drive

...lema - ocean drive 3ddd lema http://www.architonic.com/pmsht/ocean-drive-lema/1211648&nbsp; ...

3ddd

$1

B&B | Husk - H2G

... husk , om

"om" b&b | husk - h2g

3ddd

$1

Sofa ANGELO by J&D

...sofa angelo by j&d

3ddd

j&d

3ds max 2010.vray 2.40.03.file formats fbx,obj.

3ddd

$1

ferm_LIVING_baskets

...создаете себе красивый столик. в дополнение к столику идет декор.http://www.fermliving.com/webshop/shop/wire-baskets.aspx&nbsp;http://www.fermliving.com/webshop/shop/wire-baskets/wire-basket-top-3.aspx http://www.fermliving.com/webshop/shop/all-products/winebottle-candleholder-5.aspx http://www.fermliving.com/webshop/shop/geometry-vase-1.aspx в архиве max...

Designate

design_connected

$13

BL2 Table Lamp

...bl2 table lamp

designconnected

gubi bl2 table lamp computer generated 3d model. designed by dudley best , robert .

design_connected

$11

Pedal Bin and Toilet Brush

...l bin and toilet brush

designconnected

menu pedal bin and toilet brush computer generated 3d model. designed by norm architects.

design_connected

$11

Beam Table Lamp

...beam table lamp

designconnected

muuto beam table lamp computer generated 3d model. designed by chung, tom.

design_connected

$11

Gravity Floor Lamp

...gravity floor lamp

designconnected

gubi gravity floor lamp computer generated 3d model. designed by space copenhagen.

design_connected

$13

Gravity Table Lamp

...gravity table lamp

designconnected

gubi gravity table lamp computer generated 3d model. designed by space copenhagen.

design_connected

free

Mategot Trolley

...mategot trolley

designconnected

free 3d model of mategot trolley by gubi designed by mategot, mathieu.

design_connected

free

Song Coffee Tables

...song coffee tables

designconnected

free 3d model of song coffee tables by minotti designed by dordoni, rodolfo.

design_connected

free

Moon Lounge Table

...moon lounge table

designconnected

free 3d model of moon lounge table by gubi designed by space copenhagen.

design_connected

free

Fuwl Cage Table

...fuwl cage table

designconnected

free 3d model of fuwl cage table by menu designed by form us with love.

design_connected

$18

Fil Noir Dining Chair

...l noir dining chair

designconnected

minotti fil noir dining chair computer generated 3d model. designed by delcourt, christophe.

Design

design_connected

$13

BL2 Table Lamp

...designconnected gubi bl2 table lamp computer generated 3d model. designd by dudley best , robert...

design_connected

$11

Pedal Bin and Toilet Brush

...pedal bin and toilet brush computer generated 3d model. designd by norm...

design_connected

$11

Beam Table Lamp

...designconnected muuto beam table lamp computer generated 3d model. designd by chung,...

design_connected

$11

Gravity Floor Lamp

...designconnected gubi gravity floor lamp computer generated 3d model. designd by space...

design_connected

$13

Gravity Table Lamp

...designconnected gubi gravity table lamp computer generated 3d model. designd by space...

design_connected

free

Mategot Trolley

...designconnected free 3d model of mategot trolley by gubi designd by mategot,...

design_connected

free

Song Coffee Tables

...free 3d model of song coffee tables by minotti designd by dordoni,...

design_connected

free

Moon Lounge Table

...free 3d model of moon lounge table by gubi designd by space...

design_connected

free

Fuwl Cage Table

...free 3d model of fuwl cage table by menu designd by form us with...

design_connected

$18

Fil Noir Dining Chair

...minotti fil noir dining chair computer generated 3d model. designd by delcourt,...