GrabCAD

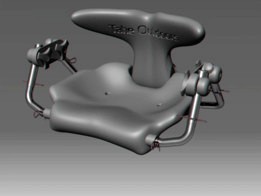

Adjustable Whale tail seat - 2nd attempt

by GrabCAD

Last crawled date: 1 year, 10 months ago

I'm happy to give you this adjustable version of my previous seat.

It is design to fit well with the current anchors present in your kayak bodies.

My design seems to be dark but I prefered spending time to find a mecanical solution rather than create powerful and colorful renderings.

The most expensive parts are the stainless steel tubes but it can maybe be replaced by a Zinc coated steel.

The four bended tubes are the same and the four straight tubes are the same too.

Adjusting to the Kayak body seems to be easy. There are a lot of combinaisons.

Adjustable to the kayak body:

You can see on animated pictures, its abilities to catch the current shoulders.

The only part which must be adjusted to the kayak body shape is the part who touch it near the twin adjusting screws.

I ensured the compatibility with a sprayskirt (the backrest touches it but it is very round and non aggressive for it).

Comfort and adjusting to the consummer's body:

Based on an ergonomic rotomolded PEHD shape, it can also easily be covered by a customisable tissu cover made from something like foam or silicon gel (non drawn).

The backrest is pushed forward by a spring and the backward bending is limited by an adjstable touching screw.

The incremental tuning of the tubing structure allows you to manage the elevation and the inclinaison of the seat.

You can modify the length of the tubes by choosing an another hole for each pin. Different technical solutions are possible like eccentric flange used on bikes.

Strong enough:

A deeper study should be done to ensure that all of the parts strength is ok but I verified the most important thing.

The steel structure is well designed and should resist up to 100kg load (see FEM post treatment picture).

Upper screws allow you to manage the inclinaison of the tubes and their tension, associate to an appropriate friction coefficient, permit to create a local clamp.

The choice of the material and the roughness of the interface is critical for the product. It is possible to use little radial grooves to improve the efficiency in this way.

Mass:

2.95 kg

Material:

Seat and backrest rotomoulded from PEHD. Stainless steel 316L (or equivalent like Zinc coated steel) tubes are included during the process (see the cut)

I took

E=1000 MPa

µ=0.46

Rp0.2=25 Mpa Max

Little plastic parts are made from massive rigid thermoplastic.

A few standard mecanical supplies.

Tubing Structure is made from stainless steel 316L or equivalent and have to resist to the corrosion (zinc coated steel could be convenient).

I took

E=200 000 MPa

µ=0.266

Rp0.2=500 MPa

Don't hesitate to ask me some questions at this address:

PSX59@Apprendre-la-CAO.com

www.Apprendre-la-CAO.com

It is design to fit well with the current anchors present in your kayak bodies.

My design seems to be dark but I prefered spending time to find a mecanical solution rather than create powerful and colorful renderings.

The most expensive parts are the stainless steel tubes but it can maybe be replaced by a Zinc coated steel.

The four bended tubes are the same and the four straight tubes are the same too.

Adjusting to the Kayak body seems to be easy. There are a lot of combinaisons.

Adjustable to the kayak body:

You can see on animated pictures, its abilities to catch the current shoulders.

The only part which must be adjusted to the kayak body shape is the part who touch it near the twin adjusting screws.

I ensured the compatibility with a sprayskirt (the backrest touches it but it is very round and non aggressive for it).

Comfort and adjusting to the consummer's body:

Based on an ergonomic rotomolded PEHD shape, it can also easily be covered by a customisable tissu cover made from something like foam or silicon gel (non drawn).

The backrest is pushed forward by a spring and the backward bending is limited by an adjstable touching screw.

The incremental tuning of the tubing structure allows you to manage the elevation and the inclinaison of the seat.

You can modify the length of the tubes by choosing an another hole for each pin. Different technical solutions are possible like eccentric flange used on bikes.

Strong enough:

A deeper study should be done to ensure that all of the parts strength is ok but I verified the most important thing.

The steel structure is well designed and should resist up to 100kg load (see FEM post treatment picture).

Upper screws allow you to manage the inclinaison of the tubes and their tension, associate to an appropriate friction coefficient, permit to create a local clamp.

The choice of the material and the roughness of the interface is critical for the product. It is possible to use little radial grooves to improve the efficiency in this way.

Mass:

2.95 kg

Material:

Seat and backrest rotomoulded from PEHD. Stainless steel 316L (or equivalent like Zinc coated steel) tubes are included during the process (see the cut)

I took

E=1000 MPa

µ=0.46

Rp0.2=25 Mpa Max

Little plastic parts are made from massive rigid thermoplastic.

A few standard mecanical supplies.

Tubing Structure is made from stainless steel 316L or equivalent and have to resist to the corrosion (zinc coated steel could be convenient).

I took

E=200 000 MPa

µ=0.266

Rp0.2=500 MPa

Don't hesitate to ask me some questions at this address:

PSX59@Apprendre-la-CAO.com

www.Apprendre-la-CAO.com

Similar models

grabcad

free

Whale tail seat - 1st attempt

...ies (4 nuts).

don't hesitate to ask me some questions at this address:

psx59@apprendre-la-cao.com

www.apprendre-la-cao.com

grabcad

free

Kayak Seat AD002 - By Adriano Ordoz Barissa

...he backrest it used a machined stainless steel shaft secured to the seat by screws which adjusts the angle with the aid of a pin.

grabcad

free

Tahe kayak seat

...erial with steel frame

sadly i wont find time to end it properly. there are still some work to do but for sure it shows my idea.

grabcad

free

Modern Office Chair

...teel tube, seat and backrest blue pvc, the (low) backrest has"bublies" for a bit of comfort...

likes are appreciated...

grabcad

free

Adjustable Kayak Mounting

...ms has not been made as the reference model did not have reference holes.

if you like it, please do not hesitate and leave like!

grabcad

free

Steel Drilling Screws with Rubber Washer for Metal

...rrosion in wet environments.

ultra-corrosion-resistant coated steel screws are more corrosion resistant than zinc-plated screws.

3dwarehouse

free

STEPPER

...: polyetilene. metallic parts: galvanized and lacquered steel s-235, stainless steel aisi-304. fixings: stainless steel aisi-304.

3dwarehouse

free

WALL

...: polyetilene. metallic parts: galvanized and lacquered steel s-235, stainless steel aisi-304. fixings: stainless steel aisi-304.

3dwarehouse

free

PULL-UP

...: polyetilene. metallic parts: galvanized and lacquered steel s-235, stainless steel aisi-304. fixings: stainless steel aisi-304.

grabcad

free

Pre Painting Process - zinc phosphatized washer container

...me material as u channels and angles.

model include manifold for spread zinc phosphatized, connections for spreads not included

Whale

3d_export

$20

Killer Whale 3D Model

...life sea false killer whale saltwater fish water aquatic mammal mid-air splashing

killer whale 3d model nolgraphic 69815 3dexport

3d_export

$95

A HumpbackWhale maya 3D Model 3D Model

...

3dexport

whale humpback rigged sea animal 3ds max high detail

a humpbackwhale maya 3d model 3d model nebulastudio 84401 3dexport

3ddd

$1

Stylized whale figure

...stylized whale figure

3ddd

статуэтка

stylized whale figure for interior decoration

3ddd

$1

Carved Sperm Whale

...ре , морской , кашалот

винтажная статуэтка кита

3d_ocean

$49

Cartoon Whale

...ush and textured with shaders and vertex map channels in 3ds max. the .fbx file format is included but may not bring across th...

3d_ocean

$8

Whale Base Mesh

...a starting point for low poly game model or for high poly sculpt. it can also be used as a production model without any requir...

3d_ocean

$10

Whale Shark

...ount: 1020 polys - formats: max /obj /fbx/3ds/dxf - high detail was preserved with 2048×2048 textures - maps included ( all in...

3d_ocean

$19

Cartoon Whale Rigged

...n max version only. perfect for game and animation. no special render needed, jst unzip and render. available formats: max v8,...

3d_ocean

$30

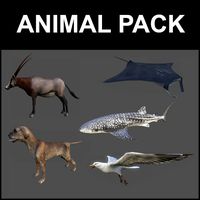

Animal Pack

...included manta max model obj orxy seagull shark skeleton whale this pack contains 5 animal models for your games/media...

3ddd

free

Fiber and Water - Nautical

...79138; 13 - red lobster; 14 - ship & whale 15 - sperm whale; 16 - atlantic cod; 17...

2Nd

3d_ocean

$12

VRay Building Materials S02 - Concrete

...vray materials library for cinema 4d. this library is 2nd of 7 in the building materials series 02. all...

3ddd

$1

Duravit 2ND FLOOR 700081

...duravit 2nd floor 700081

3ddd

duravit , ванна

с материалом

3ddd

$1

NATUZZI Dolcevita Bed L01

...material into blend and add any metallic material in 2nd slot, after that use the gradient as a mask...

3d_ocean

$14

![Dulux Paints Series Pack-02-FeatureWalls [C4D]](/t/560099.jpg)

Dulux Paints Series Pack-02-FeatureWalls [C4D]

...series pack-02-feature walls for cinema 4d description: this is 2nd material library in my series of 4 cinema 4d...

3d_ocean

$12

Stylish Bed 2

...lights lowpoly mattress pillow scene shelf this is the 2nd bed in my bedroom collection. this is using the...

3d_ocean

$5

6 VRay Dirty/Grunge Materials Pack for Cinema 4D

...grunge lib4d material pack materials metal description: this is 2nd material library in my series of 8 cinema 4d...

3d_ocean

$4

Hi-Res 2k Wall Blocks Texture 02

...stone texture wall wall blocks walls description: this is 2nd texture in my series of 5 custom made wall...

3d_ocean

$8

Optimized Low Poly Male Human Base Mesh Version1.0

...optimized quads unwrapped uv unwrapped this is an optimized 2nd version of generic male low poly base mesh (eyes,...

3d_ocean

$16

20 Standard Concrete Materials Pack for Cinema 4D

...concrete materials pack for cinema 4d description: this is 2nd material library in my series of 10 cinema 4d...

3d_ocean

$4

Gold trophy

...gold trophy 3docean 1st 2nd 3rd award black champion competition cup darts detailed first...

Tail

3d_export

$39

Fish 3D Model

...fish 3d model 3dexport realistic fish rigged autoswim maya tail scales sea ocean water multiformat fish 3d model stefanvink...

3d_export

$26

Margarita Cocktail High Detailed 3D Model

...e glass straw coaster drink liquor beverage bar party pub club

margarita cocktail high detailed 3d model vkmodels 55505 3dexport

3d_ocean

$8

Pegasus 3D Model

...horsewithwings knight pegasus race realistic rider riding safari stallion tail white whitehorse wing wings the beautiful pegasus model has...

3d_ocean

$8

The Pug dog Low poly

...of dog with a wrinkly, short-muzzled face and curled tail the breed has a fine, glossy coat that comes...

3ddd

$1

Eichholtz Prints

...polys: 2478 verts: 2516 1 - eichholtz print weasel tail 2 - eichholtz print tutti frutti 3 - eichholtz...

3ddd

$1

Z Gallerie York 5 Drawer Chest

...the case - drawers are constructed of mixed woods, dove-taild in back corners, and include high-quality hidden under-drawer guides...

3d_ocean

$29

Hair Rock

...imvu long pony ponytail realistic short style stylish tails detaild quality 3d hair for use by vfx, animation ,...

3d_ocean

$15

Low Poly Mini Skeleton Tail

...rt. he likes to stalk his prey and attack from a distance. this model has been rigged with maya 2013. the rig will not work in...

3d_ocean

$5

Tail Lift Control (VrayC4D)

...nstruction control danger elevator emergency lift mechanic play security start stop tail tail lift control

files: .3ds .c4d .obj

3d_ocean

$19

Rocking Horse

...memories model play plush rock rocking saddle stirrup swing tail toy velvet wood general this is a realistic model...

Attempt

3ddd

$1

Neverending Glory

...perspective and preserve the effect of their nobility. we attemptd to achieve big emotions through minimal forms.” jan plecháč...

3ddd

$1

Паук-гнилец / rotten-spider

...rotten-spider 3ddd персонаж , паук this is my fourth attempt to upload this model, i hope this time admins...

3ddd

$1

T A R S

...them,” visual f/x supervisor paul franklin says. “despite our attempt to erase all traces of humanoid form from it,...

3ddd

free

PK80 reitnrf

...the model: pk80™ poul kjÆrholm 1957 in an ongoing attempt to unite the sublime with the absolutely necessary, poul...

3ddd

$1

cappellini sos

...to communicate is the existential condition on which every attempt to love runs...

3d_ocean

$12

Stylized 50's TV

...stylized 50's tv 3docean electronic environment interior realityengine tv attemptng to fit the style guide of that team based...

3d_export

free

land rover swb cruiser

...land rover swb cruiser 3dexport my first attempt at designing a land rover short wheelbase and using...

3d_export

$95

sd kfz 232

...would engage similar or light units and at times attempt to capture enemy patrols. the heavy panzerspähwagen was a...

3d_export

$7

decorative set m7

...this product, which consists of 8 decorative objects, an attempt has been made to use more metal materials. this...

3d_export

$110

uss forrestal cv-59

...decommissioned in 1993, and made available as a museum. attempt to save her were unsuccessful, and in february 2014...

Adjustable

3d_export

$16

BestLite BL2 Desk Lamp 3D Model

...lamp desk modern contemporary bestlite bl2 table light lighting adjustable gooseneck materials bestlite bl2 desk lamp 3d model 3dmake_ru...

3ddd

$1

Artisan media cabinet with wall mirror

...hand forged iron frame and details. there are two adjustable shelves behind each of the three doors. open slat...

3d_ocean

$9

Vray Material Pack & Studio

...ema4d r13 & above, vray 1.9 – high detailed advanced materials. all procedural textures, easy to adjust in big scenes. com...

3d_ocean

$9

Low Poly Cafe Shop

...g standard in cinema 4d. only one material with texture, with psd file contains the solid color that you can easily adjust color.

3d_export

$40

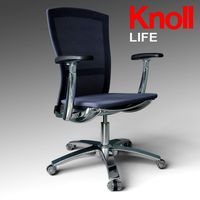

Life Adjustable Arms 3D Model

...export

life knoll arms

life adjustable arms 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl vkysi3d 107619 3dexport

3ddd

$1

Pair of French Industrial Adjustable Stools

...енный металла, древесина

высота: (76 см)

ширина: (41 см)

глубина: (41 см)

высота сиденья: (63 см)

полигонов: 195996

вершин:196166

3ddd

$1

Vertigo Bird / Boy's Lamp

...3ddd vertigo bird typology: floor lamp light emission: direct adjustable material:...

3ddd

$1

Dering Hall The Scholars Lamp

...limited http://www.deringhall.com/products/lighting/table/1939/the-scholars-lamp a bronzed effect museum reading lamp with adjustable shades and traditional double sided switches. dimensions height 81.50cm...

3ddd

$1

Davidson Lexington Table

... easy change or setup.

object at 0.0.0, clean and light scene.

the archive contains the obj & 3ds file & more previews.

3ddd

$1

Zuiver DEK-40

...and canopy (12×2,5 cm) leather strap & black cord adjustable height light source: e27, max. 60 watt dimensions shade:...

Seat

3d_export

$12

Chair 3D Model

...room dining wooden seating metal design couch office single seatr mujlan chair 3d model mujlan 6838...

3d_export

$10

Hllo Lounge Chairs 3D Model

...contemporary modern futuristic space saturn hello ring club lounge seat hllo lounge chairs 3d model jwwright 32594...

3d_export

$50

Fast Food Restaraunt Set 3D Model

...model 3dexport fast food restaraunt 3d models tables chair seat pan tray bottles support boxes interiors furniture fast food...

3d_export

$59

Sofa 17 3D Model

...couch divan living leather photoreal chair fabric home house seatng pillow cushion modern contemporary furniture sofa 17 3d model...

3d_export

$15

Armchair Philadelphia 3D Model

...furniture living bedroom lobby lounge sofa modern classic seat seatng armchair new armchair philadelphia 3d model lightxela 65332...

3d_export

$15

Seats for car set 3D Model

...eather vehicle detailed photorealistic racing sport bench front rear set vray

seats for car set 3d model trinity23 30350 3dexport

3d_export

$25

Contemporary Side Chair 12 3D Model

...chair 12 3d model 3dexport chair armless modern contemporary seatng furniture contemporary side chair 12 3d model cgaxis 29702...

3d_export

$149

North American P51D Mustang The Enchantress 3D Model

...p-51d 51d mustang fighter plane aircraft usaaf us airforce single-seat army military aviation bomber escort north american p51d mustang...

3d_export

$15

Sofa 3D Model

...sofa 3d model 3dexport sofa seat living comfortable sofa 3d model mikebibby 50046...

3d_export

$7

Chair 3D Model

...chair 3d model 3dexport chair table dinnertable chairs seatng woodenchair wood chair 3d model brennens3d 64295...