GrabCAD

Remotely operated twistlock

by GrabCAD

Last crawled date: 1 year, 10 months ago

Presented mechanism is remotely operated, like in my previous project “Remotely operated automatic twistlock” (read for details) and it use same control system with some variation.

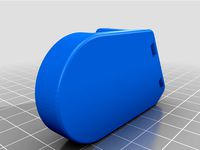

This lock mechanism is meant to be installed in bottom corner of container and eliminates need for later removal.

Base of locker is made of one piece forged alloy steel and it moves up/down via compression spring connected between end surface and inner top surface of square corner. In extended position(home), to be installed on next container, and in compression state(end), to be aligned with surface of cast square corner, when shipping container is placed on the ground.

Control mechanism is located inside of base and consists of one small dc gear motor highly reduced, high torque responsible for twist lock rotation of 90 degree. As in previous project, it use same motor spec: N20 geared, rated 60ma, 3v. Battery is again lithium thionyl chloride (Li-SOCl2) 3.6v 2.4Ah long lasting battery.

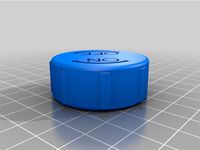

Lock/unlock position is done wirelessly. For locking/unlocking 4 twistlock system paired/programmed at the same time, using single keychain remote or handheld device. In case of remote shown on the picture, by pressing the “A” button twistlocker turn by 90 degree to lock position, and upon pressing “B” button, it turns 90degree back to home-unlocked position.

Referring to wireless communication, there is possibility of using RF 433Mhz module which is cheap and uses small car-like remote transmitter for up to 50-100 meter operational distance. Bluetooth module comes as an alternative, it uses handheld/smartphone/tablet device with control software created specially for the desired purpose.

In current design, there is posibility of adding a pushbutton (next to dc connector) for manualy operation of mechanism which excludes need for wireless transmitter/receiver.

Dc connector is elegant solution to power electronic when battery drain out, other solution is to manualy turn twist locker.

Update:

As posible solution to shaft-locker connection, as weakest point in design, I add press fit connection and weld between two part. Also hole inside of shaft larger diameter for shaft greasing.

This lock mechanism is meant to be installed in bottom corner of container and eliminates need for later removal.

Base of locker is made of one piece forged alloy steel and it moves up/down via compression spring connected between end surface and inner top surface of square corner. In extended position(home), to be installed on next container, and in compression state(end), to be aligned with surface of cast square corner, when shipping container is placed on the ground.

Control mechanism is located inside of base and consists of one small dc gear motor highly reduced, high torque responsible for twist lock rotation of 90 degree. As in previous project, it use same motor spec: N20 geared, rated 60ma, 3v. Battery is again lithium thionyl chloride (Li-SOCl2) 3.6v 2.4Ah long lasting battery.

Lock/unlock position is done wirelessly. For locking/unlocking 4 twistlock system paired/programmed at the same time, using single keychain remote or handheld device. In case of remote shown on the picture, by pressing the “A” button twistlocker turn by 90 degree to lock position, and upon pressing “B” button, it turns 90degree back to home-unlocked position.

Referring to wireless communication, there is possibility of using RF 433Mhz module which is cheap and uses small car-like remote transmitter for up to 50-100 meter operational distance. Bluetooth module comes as an alternative, it uses handheld/smartphone/tablet device with control software created specially for the desired purpose.

In current design, there is posibility of adding a pushbutton (next to dc connector) for manualy operation of mechanism which excludes need for wireless transmitter/receiver.

Dc connector is elegant solution to power electronic when battery drain out, other solution is to manualy turn twist locker.

Update:

As posible solution to shaft-locker connection, as weakest point in design, I add press fit connection and weld between two part. Also hole inside of shaft larger diameter for shaft greasing.

Similar models

grabcad

free

Remotely operated automatic twistlock

...ess fit connection and weld between two part.

let the pictures speak for themselves.

question/advice?! do not hesitate. thank you

grabcad

free

Automatic twist lock concept

...in down part locker is a shield with holes similar to claw clutch. when locker is turned, is mooved...

grabcad

free

Twitlock with automatic locking/unlocking

...g\unlocking there is no accident possible

twistlock weight is ~9 kg

maximum vertical load - 500 kn

maximum racking load - 300kn

grabcad

free

WiFi Solenoid Unlock

...ocker

second part can be unlock only with hand.

-locking had

-shaft

-hand unlocker

also it must contain charger for battery.

grabcad

free

RC - PLANE model (CONCEPTUAL)

...rfaces based on the position of joysticks on the transmitter. the control surfaces, in turn, affect the orientation of the plane.

cg_trader

$5

Rc Aircraft Design | 3D

...rfaces based on the position of joysticks on the transmitter. the control surfaces, in turn, affect the orientation of the plane.

grabcad

free

Electric Hand Truck

...handle

12v lead acid battery is recyclable

includes plug-in battery charger, battery charge detection, and auto-off functionality

grabcad

free

Locking System

...ly. most of the parts used in my system are made of standard profiles and components. the design is very robust but still light.

grabcad

free

container corner casting-Lock V-2

...sting.

it require manual operation when it is need to be unlocked, just one pull on the wire, just like semi-automatic twistlock.

grabcad

free

Fully Automatic Twistlock

...n and the lower pin remains unlocked, then you can disengage the container catching only the twistlocks. see more details on pdf.

Twistlock

thingiverse

free

Runcam 5 (or 3) Mount for Diatone Taycan Cinewoop by billyd

...the frame. prior to this the base has a twistlock that locks into the center forward slot on the...

thingiverse

free

Ford F150 Quadlock Vent Mount Cellphone Holder by Kyle1911

...the vent to reduce the moment off the phone. twistlock design was reversed from the official one. fusion 360...

thingiverse

free

Feedneck twistlock insert by poyvoy

...

i made this and it works well enough, definitely works in a pinch but someone with better tools than me can probably perfect it.

thingiverse

free

Twistlock tab for Creality frames to hold vinyl enclosures etc.

...ab for creality frames to hold vinyl enclosures etc.

thingiverse

twistlock tab for creality frames to hold vinyl enclosures etc.

thingiverse

free

Twistlock for Quokka Mount by Minus-designs

...the mount should be printed at 0,2 or thinner resolution.

for putting it on your tube , apply dubblesided tape and use 2 zippties

thingiverse

free

Belay Helper by Ralf

...the design has been useable with all the dmm twistlock hms carabiners i have come across at the climbing...

thingiverse

free

CAP FOR MSA Series 200 respirator by Admehnistrator

...series 200 respirator by admehnistrator thingiverse this is a twistlock cap to fit the msa series 200...

cg_trader

$17

Container Crane

...the container's four locking points (corner castings) using a twistlock mechanism. cranes normally transport a single container at once,...

cg_trader

$13

Container Tower Crane

...the container's four locking points (corner castings) using a twistlock mechanism. cranes normally transport a single container at once,...

cg_trader

$16

Port Crane

...the container's four locking points (corner castings) using a twistlock mechanism. cranes normally transport a single container at once,...

Remotely

3d_ocean

$29

Parrot Bebop Drone

................................... description: this 3d model created in 3ds max 2011 & render to mental ray. features: - hi...

cg_studio

$18

Digital picture frame remote low poly3d model

....max .fbx .3ds - digital picture frame remote low poly 3d model, royalty free license available, instant download after purchase.

archive3d

free

TV Remote control 3D Model

...control

tv remote control n260314 - 3d model (*.gsm+*.3ds+*.max) for interior 3d visualization.

archive3d

free

Remote control 3D Model

...ler

pult sony remote controller n210916 - 3d model (*.gsm+*.3ds) for interior 3d visualization.

3ddd

$1

SAMSUNG SMART TV CONTROL

...есь:http://www.universaltvremotecontrol.net/samsung-tv-remote/samsung-3d-plasmalcdled-tv-remote-control-bn59-01054a-12/

3d_ocean

$17

Sound bar Speaker

... sound solution. the perfect asset to include in any living space. home entertainment system free remote control included full...

3d_ocean

$12

Unmanned Air Vehicle

...flight fqm-151 gadget game-ready low-poly military plane pointer raven remotely piloted aircraft rpa rpas rq-11 scouting suav uav unmanned...

3d_ocean

$7

Remote controller

... control switcher tv remote

remote controller for tv, sound systems etc easy to edit textures photo real rendered with mental ray

3d_ocean

$8

Realistic TV/Blu-ray/DVD etc. remote

...3docean

blu-ray dvd realistic remote technology television tv

this is a model of a television, dvd, blu-ray, etc. remote control.

3d_ocean

$35

MQ-9 Predator - Drone

...predator - drone

3docean

air aircraft drone game military mq-9 poly predator remote texture uav

textures included and uv layout.

Operated

3d_export

$23

Anesthesia Delivery System 3D Model

...h healing interior medicine 3ds max vray mental ray obj fbx detailed 3d

anesthesia delivery system 3d model cgaxis 91625 3dexport

3ddd

$1

Fretwork Chest-Pearl Essence

...ract with heat and cold and do not absorb moisture as much as solid wood, which results in stronger and longer-lasting furniture.

3ddd

$1

Офисные столы Stage от VARIO

...от старейшего немецкого производителя офисной мебели vario.http://www.goodmax.ru/producers/vario/operational/stage.html

3ddd

$1

Hooker Furniture Living Room Bombay Accent Chest

...ract with heat and cold and do not absorb moisture as much as solid wood, which results in stronger and longer-lasting furniture.

3ddd

$1

Mediclinics OPTIMA M99ACS

..., mediclinics , optima сушилка для рук mediclinics optima m99acshttp://www.mediclinics.com/optima-sensor-operatedhand-dryer-m99acs ...

3ddd

$1

Музыкальный центр Samsung MX-E630D

...ртки и все что связано с текстурами имеются в архиве! никаких оптимизаций и boolean operations не применялось! сетка прилагается!

3ddd

free

RH AIRCRAFTS DECORATION SET OF 4

..., evoking a time when air travel was still glamorous and thrilling.

dimensions

46"l x 19"w x 21"h

weight: 31 lbs.

3ddd

$1

Газовый котел "Ariston MATIS 24 FF"

... 770 мм

ширина - 400 мм

глубина - 315 мм

развертки присутствую в архиве! никаких оптимизаций и boolean operations не применялось!

3d_ocean

$22

Operating Lamp System

... higher and many others. formats *.max scanline *.max vray *.max mentalray *.c4d advanced render *.c4d cinema 4d vray *.obj *.fbx

3d_ocean

$25

Chance Vought F4U Corsair rigged 3Ds WW2 aircraft

... vought f4u corsair was one of the most capable fighter bomber aircraft of the ww2 . intended for carrier operations, it was s...