GrabCAD

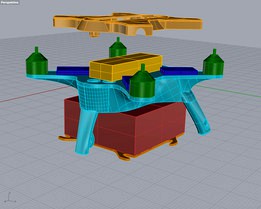

MiniQuadCopter

by GrabCAD

Last crawled date: 1 year, 10 months ago

- The QuadCopter is designed with “Rhino” CAD.

- For the size of the copter maybe a shell is better then a skeleton (like a bug).

- With a thin shell, only very little amount of infill is needed in order to connect the outer and the inner wall. I used 12% infill. The weight is between 15 an 19 grams depending on the wall thickness (see table).

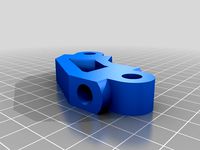

- For static reasons and to minimize the weight a tricycle undercarriage is used. Furthermore three legs are better on rough surfaces than four legs.

- The small holes in the legs of the undercarriage can be used to attach the payload itself or the cargo platform.

- The shell with the undercarriage is one part.

- The shell can be printed with FDM-technology without support structures.

- There are flat surfaces to attach the battery and the electronic with Velcro.

- To connect the battery that is located in the shell with the electronics there are two cable channels.

- Some foam rubber should be applied to the undercarriage (minimum thickness of 2 mm).

“Optional components”

- The “canopy” on top of the shell is an option to fix and to cover the electronic components. The connection to the shell is realized with two bolts (removable). The weight of the canopy is around 5 grams (ABS). It is designed as one single part that can be printed without support structures.

- The cargo platform can be used for the payload shown in the description. The weight of the platform is 2 grams (ABS).

The video shows a time lapse of the print.

- For the size of the copter maybe a shell is better then a skeleton (like a bug).

- With a thin shell, only very little amount of infill is needed in order to connect the outer and the inner wall. I used 12% infill. The weight is between 15 an 19 grams depending on the wall thickness (see table).

- For static reasons and to minimize the weight a tricycle undercarriage is used. Furthermore three legs are better on rough surfaces than four legs.

- The small holes in the legs of the undercarriage can be used to attach the payload itself or the cargo platform.

- The shell with the undercarriage is one part.

- The shell can be printed with FDM-technology without support structures.

- There are flat surfaces to attach the battery and the electronic with Velcro.

- To connect the battery that is located in the shell with the electronics there are two cable channels.

- Some foam rubber should be applied to the undercarriage (minimum thickness of 2 mm).

“Optional components”

- The “canopy” on top of the shell is an option to fix and to cover the electronic components. The connection to the shell is realized with two bolts (removable). The weight of the canopy is around 5 grams (ABS). It is designed as one single part that can be printed without support structures.

- The cargo platform can be used for the payload shown in the description. The weight of the platform is 2 grams (ABS).

The video shows a time lapse of the print.

Similar models

grabcad

free

Birdo

... go down with the weight but i'm not sure if it can be printed then or will not break while assembly of the other components.

thingiverse

free

DJI Spark Landing Leg by jhon827

...ing leg for the dji spark. it can be used with or without the prop guards. total weight for four is only 9 grams with 20% infill.

grabcad

free

Turtle Quadcopter

...ed from 0 to max and balancing conditions for all positions will not changed.

the coloring of a turtle that's just a joke ...

thingiverse

free

Titan X-50 Undercarriage Leg by KezzaN

...riage as i didn't want to see too much of the layers. the thickness of the print allows for this. i used 0.18mm layer height.

thingiverse

free

Elk's Vertex by elk

...ams. they feel really robust but i did not screw a frame together yet so still needs to be tested if two such thin shells are ok.

grabcad

free

Cargo drone quadcopter 550+ heavy lift for 3D printing

...o full assembly you need to print it with abs glue with acetone and some screws with nuts.

this project is printable and flyable.

thingiverse

free

20 Gauge Shotgun Shell by coder79

...n at the rim and for more weight. optionally, print the cap in tpu for something to dry fire against. tested in a mossberg 500.

thingiverse

free

Slenderman by cerberus333

...slenderman by cerberus333

thingiverse

prints without supports

0% infill

3 shells

(i did it in abs)

grabcad

free

Quadcopter AD02 - by Adriano Ordoz Barissa

...a support and protection for the electronic board, is fixed to the structure with m2 screw and has four holes to adapt a support.

3dwarehouse

free

Military Aircraft Payload

...raft, 'mass fraction' is normally used, which is the ratio of payload to everything else, including the rocket structure.

Miniquadcopter

thingiverse

free

Cetus MK2 Hemera / Hermes Extruder Mount

...yet but many small tpu tests such as gopro miniquadcopter mounts. i was surprised that a pla mount would...

thingiverse

free

XO-180 Miniquad by Filatech

...xo-180 miniquad by filatech thingiverse 3d printed miniquadcopter x-frame. pcb hides inside the fuselage. fc will be...