GrabCAD

Bloodhound Steering Wheel

by GrabCAD

Last crawled date: 1 year, 10 months ago

The BLOODHOUND SSC project is an incredible endeavor and a true test of engineering and design of some of the most extreme conditions and forces seen on earth. The steering wheel is obviously the most important input that the driver will use to pilot and control this rocket machine.

Like the rest of the vehicle, the steering wheel must be manufactured in the most efficient way as possible. My design for the steering wheel is completely based off the need to manufacture this wheel at a reasonable cost and in a timely manner. Though, the form complements the effort in designing this functional wheel.

The basic form of my wheel is a derivative of what most modern race cars and sports cars use today. A closed wheel ensures safe and reliable contact points for grip, while the flat top and bottom save space from the driver’s legs and eyesight. The tri-spoke design secures the rigidity of the outer wheel to the center hub. The wheel is designed with a standard six hole pattern to attach many modern, off-the-shelf quick release systems. The air brakes and chute releases are actuated by buttons mounted near the driver’s two thumbs, thus, there is no need to loose grip while engaging these operations. For thrust increase, there is a trigger mounted on the back of the right side of the wheel, engaged with the index finger. The further the trigger is engaged, the thrust is obviously increased.

In the pursuit of manufacturability, aluminum was the chosen material of fabrication for this wheel. Weight is an apparent concern for a vehicle of this status, though my personal opinion was that composites were simply too complicated for a part like this. With two and half years of solid experience fabricating molds and composite parts (fiberglass, carbon fiber, kevlar) for my university’s solar race car, I believe the complexity of these carbon parts would take a long time to fabricate and would ensue unnecessary costs. My goal was to design this steering wheel so that it could be machined out of one block of solid aluminum on a 3-axis CNC mill. With the proper CAM and end mills, this should be possible. For the grips on the side, the block would be machined a little bit more than the desired grip size. After machining, the wheel would be taped off, and the sides would be coated with a spray on rubber coating. This rubber coating would slightly reduce vibrations transmitted to the driver and dramatically increase grip. Also, on the back side of the steering wheel, there are quite a few speed holes to reduce the mass and weight of the wheel. I am currently approximating the weight to be around one to two pounds. The two grips on the sides are formed to be ergonomically comfortable and provide the most amount of control as possible. Indentations for the thumbs on the top are provided while the remaining four fingers wrap around the wheel easily.

There was no effort made in including an LCD display or ‘rev’ lights, because this would only complicate the design greatly and there are plans for a dashboard, where these instruments should be able to be mounted. Also, any display on a wheel will vibrate and rotate, increasing the difficulty to properly read the necessary information for the driver.

Thank you for taking the time to look at my design. Please leave me feedback and suggestions!

Kevin

Like the rest of the vehicle, the steering wheel must be manufactured in the most efficient way as possible. My design for the steering wheel is completely based off the need to manufacture this wheel at a reasonable cost and in a timely manner. Though, the form complements the effort in designing this functional wheel.

The basic form of my wheel is a derivative of what most modern race cars and sports cars use today. A closed wheel ensures safe and reliable contact points for grip, while the flat top and bottom save space from the driver’s legs and eyesight. The tri-spoke design secures the rigidity of the outer wheel to the center hub. The wheel is designed with a standard six hole pattern to attach many modern, off-the-shelf quick release systems. The air brakes and chute releases are actuated by buttons mounted near the driver’s two thumbs, thus, there is no need to loose grip while engaging these operations. For thrust increase, there is a trigger mounted on the back of the right side of the wheel, engaged with the index finger. The further the trigger is engaged, the thrust is obviously increased.

In the pursuit of manufacturability, aluminum was the chosen material of fabrication for this wheel. Weight is an apparent concern for a vehicle of this status, though my personal opinion was that composites were simply too complicated for a part like this. With two and half years of solid experience fabricating molds and composite parts (fiberglass, carbon fiber, kevlar) for my university’s solar race car, I believe the complexity of these carbon parts would take a long time to fabricate and would ensue unnecessary costs. My goal was to design this steering wheel so that it could be machined out of one block of solid aluminum on a 3-axis CNC mill. With the proper CAM and end mills, this should be possible. For the grips on the side, the block would be machined a little bit more than the desired grip size. After machining, the wheel would be taped off, and the sides would be coated with a spray on rubber coating. This rubber coating would slightly reduce vibrations transmitted to the driver and dramatically increase grip. Also, on the back side of the steering wheel, there are quite a few speed holes to reduce the mass and weight of the wheel. I am currently approximating the weight to be around one to two pounds. The two grips on the sides are formed to be ergonomically comfortable and provide the most amount of control as possible. Indentations for the thumbs on the top are provided while the remaining four fingers wrap around the wheel easily.

There was no effort made in including an LCD display or ‘rev’ lights, because this would only complicate the design greatly and there are plans for a dashboard, where these instruments should be able to be mounted. Also, any display on a wheel will vibrate and rotate, increasing the difficulty to properly read the necessary information for the driver.

Thank you for taking the time to look at my design. Please leave me feedback and suggestions!

Kevin

Similar models

grabcad

free

Spokeless Steering Wheel Button Placement for BLOODHOUND SSC Steering Wheel Challenge

...two-spoke-steering-wheel-button-placement-for-bloodhound-ssc-steering-wheel-challenge-for-bloodhound-ssc-steering-wheel-challenge

grabcad

free

BLOODHOUND SSC Steering Wheel

...osition. all the buttons are in logical place and easy accessible. materials: rubber for grip, composite carbon for light weight.

grabcad

free

BloodHound Steering Wheel Design Challenge

...s on the right are for the brake chutes (main and backup).

the triggers are to light-up, increase power, and shutdown the rocket.

grabcad

free

Two Spoke Steering wheel button placement for bloodhound ssc steering wheel challenge

...two-spoke-steering-wheel-button-placement-for-bloodhound-ssc-steering-wheel-challenge-for-bloodhound-ssc-steering-wheel-challenge

grabcad

free

Spokeless version of http://grabcad.com/library/two-spoke-steering-wheel-button-placement-for-bloodhound-ssc-steering-wheel-challenge for bloodhound ssc steering wheel challenge

...-wheel-challenge

http://grabcad.com/library/two-spoke-steering-wheel-button-placement-for-bloodhound-ssc-steering-wheel-challenge

grabcad

free

Bloodhound SSC Steering Wheel Concept

...r-brake on both sides so the driver can use either hands.

- r for reserve chute (left) c for primary chute (right)

ankishu gupta

grabcad

free

Bloodhound SSC Steering Wheel-EM-2

...o i created 0, 50, 100% markers to help the driver judge the amounts of power leftover while increasing power.

by: evan mendoza

grabcad

free

4 spoke aircraft style steering wheel button placement for bloodhound ssc steering wheel challenge

...two-spoke-steering-wheel-button-placement-for-bloodhound-ssc-steering-wheel-challenge-for-bloodhound-ssc-steering-wheel-challenge

grabcad

free

BLOODHOUND CONCEPT 2

...steering wheel more of a joystick approach this time. similar button layout to keep the design clean. the trigger...

grabcad

free

Bloodhound SSC Steering - Dev N Malviya

...oid hitting any button accidentally at high speeds. i have designed the grips so that they are firm to hold on to at high speeds.

Bloodhound

humster3d

$75

3D model of Bloodhound SSC 2015

...detailed 3d model of bloodhound ssc 2015 in various file formats. all our 3d models were created maximally close to the original.

3d_export

$15

apex - bloodhound

...r>.3ds<br>.obj<br>.fbx<br>.mtl<br>.stl<br>.blend<br>polys : 33.238<br>verts : 40.134

thingiverse

free

Apex Legends- Bloodhound Heirloom by Sorijako

...apex legends- bloodhound heirloom by sorijako

thingiverse

remix easier for printing

thingiverse

free

Apex Legends Apex Predator Plaque by Savag3Calib3r

...easy and even hanging or mounting, mirrored ravens bites (bloodhound heirlooms) for added flair and the popular quote from...

thingiverse

free

Raven's Bite - Apex Legends by yzako

...- apex legends by yzako thingiverse apex legends heirloom, bloodhound raven's bite, the prop has 36 cm long, handmade...

thingiverse

free

Bloodhound Mask helmet and other bits WIP v1.0

...er person.

you will need to drill holes for the capsule so that you can breathe.

i can also upload the ski mask pattern if needed

thingiverse

free

Bloodhound RavensBite Heirloom Axe by NKOrange

... pictures of it hit me up on my twitter.

please credit me if you post your print or use this file.

https://twitter.com/nkorange_

thingiverse

free

Freelancer Pirate fighter "Wolfhound" by HotSliceOfJesus

...one does not suffer the same problems as the "bloodhoundquot; as a model so it should print ok. careful...

thingiverse

free

Freelancer Pirate Fighter "Bloodhound" by HotSliceOfJesus

... not sure if that is how it is actually designed as a model or a software/slicing issue. let me know if you can fix the problems.

thingiverse

free

Rocket Power by MiniSumo

...been working with the institution of mechanical engineers and bloodhound ssc with balloon powered cars at a tomorrow's engineer's...

Steering

3d_ocean

$7

Real Ship Steering Wheel

...steer steering wheel

wooden ship steering built in : cinema 4d r14 format include : - .obj - .c4d i hope your enjoy, thank you ….

3d_export

$27

Decorative nautical helm 3D Model

...decorative nautical helm 3d model 3dexport helm decorative nautical steering wheel ship fleet sea rudder gear tiller captain navigation...

3ddd

$1

Vitra / Steering Wheel

...vitra / steering wheel

3ddd

vitra

dimensions:

dia 30.5cm x d 7.5cm

3ddd

$1

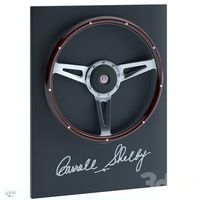

Shelby Cobra steering wheel

...рого, и оставить деревянный обод на втором уровне.

при сглаживании по умолчанию 50к полигонов.

диаметр рулевого колеса 15 дюймов.

3d_ocean

$5

Binocular

...binocular experience far away forest glasses instrument mountains old steering low-polygon model of binocular with 662 faces. ideal for...

3d_ocean

$59

1959 Cadillac Eldorado Biarritz

...coupe eldorado interior leather lincoln lowpoly seat sedan series steering a very accurate model of a 1959 cadillac eldorado...

3d_ocean

$59

1959 Cadillac Eldorado Coupe

...coupe eldorado interior leather lincoln lowpoly seat sedan series steering a very accurate model of a 1959 cadillac eldorado...

3d_ocean

$40

Bicycle set

...hobbies parts parts simulator simulator spokes spokes sport sport steering steering wheel wheel bicycle set include 3d models: 3...

3d_ocean

$16

Steering Wheel

...d in cinema 4d. this is perfect for any car render, close up or far away shots. all the materials shown in the preview image a...

3d_ocean

$7

Tesla Model S Steering Wheel

...s in four formats: -.blend, rendered with cycles, as seen in the images; -.obj, with materials applied and textures; -.dae, wi...

Wheel

3d_export

$7

Rim 3D Model

...rim 3d model 3dexport rim wheel car keychains rim 3d model dosoriofp78431 90998...

3d_export

$15

American Racing Classic 200S 16 inch Rim 3D Model

...inch rim 3d model 3dexport american racing equipment classic wheel rim tire spoke aluminum metal steel rally 16 inch...

3d_export

free

Download free Wheel Subaru STI 3D Model

...download free wheel subaru sti 3d model

3dexport

wheel subaru sti

wheel subaru sti 3d model ones 38933 3dexport

3d_export

$10

ADV08DC Rim 3D Model

...adv08dc rim 3d model 3dexport car wheel rim adv adv08 dc race racing motorsport adv08dc rim...

3d_export

$59

Old workbag 3D Model

...suit baggage luggage summer beach travel trip dress clothes wheel people airport plane briefcase old work old workbag 3d...

3d_export

$75

Audi R9 Prototype Car 3D Model

...fast sport luxury r8 drive auto mobile automobileautomotive speed wheel photorealistic design futuristic audi r9 prototype car 3d model...

3d_export

$89

Chevrolet Camaro 2013 HotWheels SE Convertible 3D Model

...r vehicle auto automobile cars 3d model higt poly

chevrolet camaro 2013 hotwheels se convertible 3d model creatord 71207 3dexport

3d_export

$129

BMW M5 2012 3D Model

...2012 car vehicle transport speed sport german people drive wheel rigged photorealistic serie luxury f10 e60 sedan interior bmw...

3d_export

$10

Office desk 3D Model

...model 3dexport desk office detailed furniture wood wooden drawer wheel office desk 3d model matvic 70261...

3d_export

$89

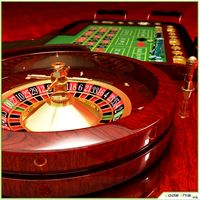

Roulette Table Casino 3D Model

...cupholders cards gambling betting las vegas texas holdem felt wheel roulette table casino 3d model codethislab 70198...