GrabCAD

Truck Underrun using SimScale for FEA

by GrabCAD

Last crawled date: 1 year, 10 months ago

Mass: 44.92 Kg

Minimum Thickness: 10 mm

Maximum Stress P1: 350.95 MPa

Maximum Stress P2: 324.22 MPa

Maximum Stress P3: 295.33 MPa

Maximum Deflection P1: 15.095 mm

Maximum Deflection P2: 2.636 mm

Maximum Deflection P2: 3.986 mm

As can be seen by the stress values, there are some areas that can still be optimized. The main goal I had for this particular design was to get the mass under 45 Kg while meeting the design criteria.

I ran through several different iterations that included getting the mass down below 48 Kg while keeping deflection between 2-6 mm all around. However, after thinking about this, I decided that weight would be a better area to focus on due to the affect in gas mileage over the lifetime of the truck and trailer.

I would continue to focus on optimizing the weight, but due to many difficulties encountered with SimScale, and the amount of time it takes to run through one complete iteration from uploading the STEP file to showing results, I set my goal at 45 Kg and stopped after reaching it. I believe that with extra time another 2-3 Kg could be saved.

UPDATE:

After seeing a few other people take my approach, I went ahead and did a single "T" beam as well. However, SimScale kept crashing (probably because everyone is getting this in last minute).

I tried to follow similar design ideas as my first model, but with a few changes to allow for the stress to propagate in an efficient way.

The mass of this model is 43.02 Kg, but like I said, I don't have any stress calculations. I have attached several renderings of it in this project.

As can be seen, manufacturing was not thought about (as per the problem statement). This would be a nightmare to actually fabricate as it is currently made, but with a few changes this could be made from as few as 3 pieces.

Minimum Thickness: 10 mm

Maximum Stress P1: 350.95 MPa

Maximum Stress P2: 324.22 MPa

Maximum Stress P3: 295.33 MPa

Maximum Deflection P1: 15.095 mm

Maximum Deflection P2: 2.636 mm

Maximum Deflection P2: 3.986 mm

As can be seen by the stress values, there are some areas that can still be optimized. The main goal I had for this particular design was to get the mass under 45 Kg while meeting the design criteria.

I ran through several different iterations that included getting the mass down below 48 Kg while keeping deflection between 2-6 mm all around. However, after thinking about this, I decided that weight would be a better area to focus on due to the affect in gas mileage over the lifetime of the truck and trailer.

I would continue to focus on optimizing the weight, but due to many difficulties encountered with SimScale, and the amount of time it takes to run through one complete iteration from uploading the STEP file to showing results, I set my goal at 45 Kg and stopped after reaching it. I believe that with extra time another 2-3 Kg could be saved.

UPDATE:

After seeing a few other people take my approach, I went ahead and did a single "T" beam as well. However, SimScale kept crashing (probably because everyone is getting this in last minute).

I tried to follow similar design ideas as my first model, but with a few changes to allow for the stress to propagate in an efficient way.

The mass of this model is 43.02 Kg, but like I said, I don't have any stress calculations. I have attached several renderings of it in this project.

As can be seen, manufacturing was not thought about (as per the problem statement). This would be a nightmare to actually fabricate as it is currently made, but with a few changes this could be made from as few as 3 pieces.

Similar models

grabcad

free

SimScale Truck Underrun Challenge

...3 (steel).

i've included a screen shot for load cases p1, p2, and p3 for stress and displacement from the simscale analysis.

grabcad

free

Optimized Truck Underrun Protection Device

...se (1.25 mpa applied pressure):

maximum von mises stress: 102.2 mpa

maximum deformation: 0.6701 mm

minimum factor of safety: 3.47

grabcad

free

SimScale Truck Underrun Protection Challenge

...imal v.m. stress <355 mpa

maximal deformation - - mm

p3 load case

maximal vm stress < 355 mpa

maximal deformation - - mm

grabcad

free

truck underrun protection

...e mass of truck underrun protection is 85.7 kg.

at load p1- stree 350 mpa , 12.01 mm

p2- 262 mpa, 2.97mm

p3-147 mpa , 1.26 mm

grabcad

free

SimScale Truck Underrun Protection

...image :p2 result.png

p2 = 25.0 bar = 25.0 × 105 pa

p1 load case <355 mpa

p2 load,case <355 mpa

p3 load,case <355 mpa

grabcad

free

truck underrun protection

...ding condition,

at load p1- stress (von;mises)-307 mpa , deformation-7.3 mm

at load p2-346 mpa ,3.7 mm

at load p3-170 mpa ,1.9 mm

grabcad

free

Underrun protector

...m

p2 max pressure is 322.076 mpa the max displacement is 3.092 mm

p3 max pressure is 187.402 mpa the max displacement is 1.518 mm

grabcad

free

Truck Underrun Protection-Sturdy V2

...ass is 56.367 kg. maximum deflection is 6.79 mm. maximum von-mises stress is

355 mpa.

edit

uploaded new iges file and results.

grabcad

free

Underrun Protection_Version DT-D

...nt = 0.534 mm ; max.von mises stess = 186.6 mpa). load case p3 : (max.displacement = 0.537 mm ; max.von mises stress = 97.4 mpa).

grabcad

free

Underrun Protection_Version DT-C

...t = 0.64 mm ; max.von mises stess = 309. 3 mpa). load case p3 : (max.displacement = 1.38 mm ; max.von mises stress = 248.49 mpa).

Simscale

thingiverse

free

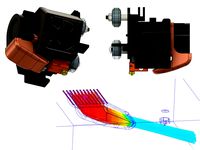

HUSH! Quiet cooler for Ender 2 / 3 / 3V2 by Mikael70

...fan 5015 cooling from two directions cfd calculations with simscale note that the flow from a radial fan is...

thingiverse

free

CR6 SE - Dragon Hot-End / V6 - Cover & Part Cooler by 3DChanh

...heigh w/ no fan shroud) - https://cdn.thingiverse.com/assets/f0/99/55/a7/48/cr6_to_dragon_hotend_adapter_match_nozzle_hight_without_fan_shroud.stl simscale project: https://www.simscalecom/projects/cphuong/cr6_duct/ ...

thingiverse

free

Tenlog TL-D3 Pro (Dual) 5015 Fan Mod for Stock Metal Shroud by Buriaku

...distributed quite evenly. airflow was examined using fluid simulation (simscale and water tests. for assembly, the metal shroud needs...

thingiverse

free

Sovol-Luefterhalter für DragonFly Hotend (Neu) by thro42

...diese version habe ich auf simscale einige simulationen durchgeführt. https://www.simscalecom/projects/rthomitzek/phaetus_dragonfly_bmo_l-fter/ so das diese version erheblich effektiver arbeitet. zumindest mein...

thingiverse

free

SOVOL SV01 X Linear Rail mit BIQU-H2 by thro42

...den biqu-h2. der lüfter kanal wurde auf simscale simuliert https://www.simscalecom/projects/rthomitzek/biqu_h2-5015fan/ ihr findet ein video des anbaus und der klipper...

thingiverse

free

SOVOL SV01 BIQU-H2 Adapter by thro42

...zu haben. der lüfter kanal wurde auf simscale simuliert https://www.simscalecom/projects/rthomitzek/biqu-h2/ ihr findet ein video des anbaus und der marlin...

grabcad

free

Simscale Truck Underrun

...simscale truck underrun

grabcad

52kg

grabcad

free

Simscale Truck Underrun Challenge

...2 and since cannot run simscale due to low system configuration, simulated in solidworks simulation.

mass of the product : 61 kg

grabcad

free

Curved Truck Underrun

...light without compromising the overall strength. thank you to simscale for providing such a fantastic service, i really enjoyed...

cg_trader

free

Curved Truck Underrun

...light without compromising the overall strength. thank you to simscale for providing such a fantastic service, i really enjoyed...

Underrun

thingiverse

free

Tamiya Truck underrun guard rear curved

...ar curved

thingiverse

curved underrun guard for the rear of stock tamiya trucks. can be mounted easily on the stock screw holes.

thingiverse

free

Audi TT underrun protection nut by Germanbratwurst

... infill

0,15mm layers

0.4 mm nozzle

i have printed it with flexible filament, but i think it will also works with other materials

thingiverse

free

Burson Conductor v1 usb card upgrade from Tenor TE8802L to XU208 XMOS (Lusya)

...was not clean enough with many clicks/pops audio dropouts/buffer underrun. after finding that not even the original cm6631 card...

thingiverse

free

Ferrex (Aldi) 20V Battery Adapter by Thinger13

...stop discharging before the safe minimum voltage level is underrun the safe minimum voltage per 20v pack may be...

thingiverse

free

Bosch 18V Battery Adapter by Thinger13

...the safe minimum voltage level is underrun. after an underrun the charger may refuse to load the battery or...

grabcad

free

Simscale Truck Underrun

...simscale truck underrun

grabcad

52kg

grabcad

free

Simscale Truck Underrun Challenge

...2 and since cannot run simscale due to low system configuration, simulated in solidworks simulation.

mass of the product : 61 kg

grabcad

free

Curved Truck Underrun

...

thank you to simscale for providing such a fantastic service, i really enjoyed doing the stress analysis simply in the browser.

cg_trader

free

Curved Truck Underrun

...ice, i really enjoyed doing the stress analysis simply in the browser. underrun part truck lamps light vehicle other vehicle part

grabcad

free

Truck Underrun

... load condition

vom mises stress: 247 m pa

deformation: 2mm

under p3 load condition

von mises stress: 216m pa

deformation: 1.1mm

Fea

3ddd

$1

Fornelli FEA 60 Merletto Ivory

... fornelli

духовой шкаф fornelli fea 60 merletto ivory

сайтhttp://fornelli.ru/catalog/2190/detail17357.html

3d_export

$5

spin bike

...render in keyshot, suitable for fea, minor changes after fea lead to it to be easily...

3d_export

$120

tesla

...created easily with your idea. also we can do fea and cfd analysis using ansys & solidworks with technical...

thingiverse

free

3/4 point and cantilever bending test by MSE1234

...modulus and then beam geometry and finally cad and fea analysis. the lesson plans run through points in the...

thingiverse

free

3/4 point and cantilever bending test by MSE1234

...modulus and then beam geometry and finally cad and fea analysis. the lesson plans run through points in the...

thingiverse

free

Xiaomi M365 Rim Protector changing tire tyre wheel hub saver by TheNit

...supone que haga las cosas más fáciles, solo menos fea :) mi forma favorita de recibir agradecimiento es subiendo...

thingiverse

free

Seresto Fea Collar end pieces by obsesscions

...iece always get thrown away. well not anymore.

elastic through the loops and epoxy them into the collar

all set with extra collar

thingiverse

free

Bearing Preload Tool for Hollowtech 2 by halmos_designs

...uses considerably less material than the standard tool. an fea shows the minimal strain and von mises stress when...

thingiverse

free

curtain rod for hanging over a blind on a slider by jrank1967

...thingiverse after a failure i redesigned and ran an fea this one will not...

thingiverse

free

Shopping bag handle by The_Lord_of_the_Things

...is very sturdy and it has been tested via fea in inventor 2017 following the galileo-rankine-navier criterion (every force...

Truck

3d_export

$99

Mercedes Atego 2014 short 3D Model

...container box truck medium mercedes-benz delivery rigid german european boxtruck heavy short swb realistic mercedes atego 2014 short 3d...

3d_export

$99

MercedesBenz Axor Tractor Truck 2011 3D Model

...012 2013 2014 2015 2016 truck heavy duty trucks industrial

mercedesbenz axor tractor truck 2011 3d model humster3d 93185 3dexport

3d_export

$129

Scania R1000 2014 AeroTrailer 3D Model

...aerotrailer 3d model 3dexport aero 2013 2014 2015 2016 truck concept prototype tractor 2017 semi transport scania r1000 r-1000...

3d_export

$75

Family Minivan 3D Model

...family minivan 3d model 3dexport car vehicle truck suv minivan transportation family minivan 3d model vanishingpoint 73088...

3d_export

$75

Trailfinder SUV 3D Model

...trailfinder suv 3d model 3dexport car vehicle truck suv minivan transportation trailfinder suv 3d model vanishingpoint 73087...

3d_export

$99

Iveco Trakker Log Truck 4axis 2012 3D Model

...-axis 2011 2012 2013 2014 truck heavy duty trucks industrial

iveco trakker log truck 4axis 2012 3d model humster3d 59446 3dexport

3d_export

$99

MAN TGS Skip Loader Truck 2012 3D Model

...011 2012 2013 2014 2-axis heavy industrial trucks germany german

man tgs skip loader truck 2012 3d model humster3d 70332 3dexport

3d_export

$99

Mercedes Actross AeroTrailer 2014 3D Model

...2012 2013 2014 2015 2016 mercedes mb mercedes-benz benz truck tractor semi transport hevy wheeler trailer tir actros aerotrailer...

3d_export

$50

TruckMan 3D Model

...truckman 3d model

3dexport

truck man container heavy vehicle

truckman 3d model daminda3d 49312 3dexport

3d_ocean

$9

Low Poly Motel

...poly low poly factory model old poly tower town truck vehicle vehicles village windows files: .3ds .c4d...

Using

design_connected

free

Fuwl Cage Table

...fuwl cage table

designconnected

free 3d model of fuwl cage table by menu designed by form us with love.

3d_export

$99

Buick Skylark convertible 1964 3D Model

...lassic 2-door coupe sport convertible general motors us american

buick skylark convertible 1964 3d model humster3d 90963 3dexport

3d_export

$25

3D Models Mixed Use Building 70 3D Model

...op condo mixed use multi story city game ready vray scanline max

3d models mixed use building 70 3d model vkmodels 71944 3dexport

3d_export

$99

Chevrolet El Camino 1959 3D Model

...959 1960 chevy 2-door coupe classic vintage utility pickup us american

chevrolet el camino 1959 3d model humster3d 74295 3dexport

3d_export

$89

Lamborghini Aventador LP 700 4 US spec 3D Model

... avto car vehicle auto automobile cars 3d model high poly

lamborghini aventador lp 700 4 us spec 3d model creatord 82681 3dexport

3d_export

$99

Chevrolet Cruze hatchback 2012 3D Model

...chback sport city urban style us doors auto chevy compact family

chevrolet cruze hatchback 2012 3d model humster3d 38416 3dexport

3d_export

$95

Falcon3D MD 80 Hawaiian 3D Model

...ght cargo corporate mcdonnell douglas us plane planes jet jetliner md-80

falcon3d md 80 hawaiian 3d model falcon3d 73148 3dexport

3d_export

$95

Falcon3D MD 80 Fast Cargo 3D Model

...t cargo corporate mcdonnell douglas us plane planes jet jetliner md-80

falcon3d md 80 fast cargo 3d model falcon3d 72916 3dexport

3d_export

$25

3D Models Building 85 3D Model

...ential retail shop apartment hotel lowpoly game ready 3d max vray scanline

3d models building 85 3d model vkmodels 74339 3dexport

3d_export

$25

3D Models Building 65 3D Model

...flat condo commercial balcony mixed use multi story game ready street city

3d models building 65 3d model vkmodels 71242 3dexport