GrabCAD

Lurssen wind problem

by GrabCAD

Last crawled date: 1 year, 10 months ago

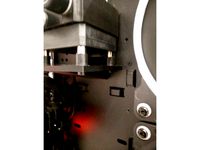

This solution uses the gap between the actuator and the fluid container to permit only a small amount of fluid to pass. The density of the fluid versus the gap will determinate the maximum rotational speed and acceleration of the door. This solution has some more details which need to be explained.

1- The door hinge is continuous to permit the glass to pass the load gently to the supports otherwise it may suffer torsion for the unbalanced load.

2- The thrust bearing on the top of the ceiling support most of the mass of the structure but another damper can be used in that place, if needed.

3- Underneath the fluid container is a gap which can receive an electric heather to maintain the fluid temperature above certain level.

4- On the limits of actuator movement connectors can be placed to permit an hydraulic pump to move the door in case of extreme winds.

5- The actuator has been designed for a torsion load of 400 Nm.

6- All the structural parts are intended to be in aluminum 6061. This material is easily machined, welded and can be heat treated (T4, T6) to gain more strength.

7- The cover and the fluid container are meant to be threaded. The sealing has made for O-rings. Once is mounted, its maintenance free.

8- If needed the fluid container can be filled with magnetorheological fluid. In case of strong winds the computer of the ship can change the damping coefficient of the system.

9- The mounting points can’t be designed without the exact model of the installation site.

10- The actual course of the door is 140°.

1- The door hinge is continuous to permit the glass to pass the load gently to the supports otherwise it may suffer torsion for the unbalanced load.

2- The thrust bearing on the top of the ceiling support most of the mass of the structure but another damper can be used in that place, if needed.

3- Underneath the fluid container is a gap which can receive an electric heather to maintain the fluid temperature above certain level.

4- On the limits of actuator movement connectors can be placed to permit an hydraulic pump to move the door in case of extreme winds.

5- The actuator has been designed for a torsion load of 400 Nm.

6- All the structural parts are intended to be in aluminum 6061. This material is easily machined, welded and can be heat treated (T4, T6) to gain more strength.

7- The cover and the fluid container are meant to be threaded. The sealing has made for O-rings. Once is mounted, its maintenance free.

8- If needed the fluid container can be filled with magnetorheological fluid. In case of strong winds the computer of the ship can change the damping coefficient of the system.

9- The mounting points can’t be designed without the exact model of the installation site.

10- The actual course of the door is 140°.

Similar models

thingiverse

free

Pump Mount - Thermaltake Core P5 EKWB FLuid Gaming by MacNite

...se this with other cases: the "mounting clamp/slot" is 29 x 17.5 mm and the "gap" for the sheet metal is 1mm.

thingiverse

free

Case for Homematic HM-LC-SW1-BA-PCB actuator by MadMarvin

...uator which is available as kit and needs a case.

design is big enough to hold a 9v block inside.

can be printed without support.

thingiverse

free

Snapping USB support Phone holder by my_Evil_Twin

...stic

this phone holder was designed by ftc team robocracy 9773. you can learn more about us on our website: www.ftcrobocracy.org

grabcad

free

Hands-Free Door Handle Opener

... that meet classification performance parameters 1 according to din en1906, i.e. a tensile load 300 n and torsional torque 20 nm.

thingiverse

free

12V Socket Casing - surface mount by kschoelpple

...ing the provided mounting holes. it also has a hook which can be used to wind cable around to prevent plug from being pulled out.

thingiverse

free

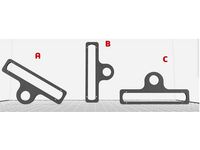

Structure Sensor Mount For Device Clamp by aishwaryau

...he clamp you own. no more rubber bands!

printing in orientation b does not require the use of supports, use supports for a and c.

thingiverse

free

Support for Articulating Raspberry Pi Camera Mount by fizzyade

... gather an idea of how much, you should open an existing file with a support structure and look how the two parts are positioned.

grabcad

free

Structural Analysis of Solar Panel Support Structure

...ucture

grabcad

structural analysis of solar panel support structure

mesh type: 2d

loads considered: wind load and self weight

thingiverse

free

Lee Load Master Pro Die Case by ooeygui

...n't need supports to print. the cap - which comes with .223 and blank - holds the upper part of the dies relatively securely.

grabcad

free

FLAP-BEARING-BRACKET-V82

... material

use only 2 of the 4 screws, save more weight

cell structure design allows for even more fine tuning of individual areas

Lurssen

grabcad

free

lurssen brake

...t can be usable in both types.

small dimmensions locking bolts diameter=5mm.

blowing force can be set by spring factor adjusting.

grabcad

free

One of Seven

...one of seven grabcad lurssen werft dampening device as i read through the text...

grabcad

free

Lurssen door

...how how it works:

http://youtu.be/pnasxay_gp0

http://youtu.be/owue2-y6knw

http://youtu.be/81a04hf2jjo

http://youtu.be/tvg-o5uwoak

grabcad

free

Lurssen door dampening

...ve which is maintained open by a low voltage electro magnet which releases on loss of signal from the fcp

2) fixings & seals

grabcad

free

Lurssen Magnetically Damped Hinge

...pin are the only moving parts and the non corrosive materials used, will mean that the hinge will be relitively maintenance free.

grabcad

free

Lurssen Wind Breaker - Rotary Oil Damper

..., the rotary oil damper mechanism could potentially replace the lower or upper hinge assembly in either the floor or the ceiling.

grabcad

free

Lurssen combined windbreaker door-hinge system

...(inside the oil tank can be carbon steel)

- can be used in multiple yacht doors, implementing an standard on many different ships

grabcad

free

lurssen-Dampening device

...lurssen-dampening device

grabcad

material: stainless steel

grabcad

free

LURSSEN 2

...lurssen 2

grabcad

lurssen 2

Wind

3d_export

$99

Renault Wind 3D Model

...model france coupe roadster compact city sport eco car vehicle twingo concept door

renault wind 3d model humster3d 33037 3dexport

3d_export

$30

Kite rigged 2 3D Model

...2 3d model 3dexport kite toy tethered aircraft fly wind sky child children kid hobby cometa detailed rigged kite...

cg_studio

$15

Low Poly Wild West Wind Mill3d model

...ity

.fbx .3ds .max .obj - low poly wild west wind mill 3d model, royalty free license available, instant download after purchase.

3d_export

$10

Wind Turbine 3D Model

... hawt horizontal axis electric

wind turbine 3d model download .c4d .max .obj .fbx .ma .lwo .3ds .3dm .stl firdz3d 107121 3dexport

archive3d

free

Stair 3D Model

...stair 3d model archive3d stair spiral stairs staircase windng stairs stair modern n271213 - 3d model (*.gsm+*.3ds) for...

archive3d

free

Stair 3D Model

...stair 3d model archive3d stairs staircase spiral stairs windng stairs stair s n120412 - 3d model (*.3ds) for...

archive3d

free

Stair 3D Model

...stair 3d model archive3d stairs spiral stairs windng stairs stair s n150612 - 3d model (*.3ds) for...

archive3d

free

Stair 3D Model

...stair 3d model archive3d stair spiral stairs stairs staircase windng stairs stair n191114 - 3d model (*.gsm+*.3ds) for interior...

archive3d

free

Stairs 3D Model

...stairs 3d model archive3d stairs staircase spiral stairs windng stairs stairs carlos batista n230412 - 3d model (*.gsm+*.3ds)...

archive3d

free

Stair 3D Model

...stair 3d model archive3d stair spiral stairs staircase windng stairs stair round n250314 - 3d model (*.gsm+*.3ds) for...

Problem

3d_ocean

$17

Low Poly Farm House

...-if you have any questions or if you have problem after purchase. i am willing to help and answer...

3d_ocean

$2

Deadgrass

...you come back to life! tileable supported! have any problem contact...

3d_ocean

$2

Cementwall

...cement walls were very sharp! tileable support! have any problem contact...

3ddd

$1

Fretwork Chest-Pearl Essence

...time-tested english or french dovetail construction, for years of problemfree use. plywood drawer bottoms are attached to plywood drawer...

3ddd

$1

Hooker Furniture Living Room Bombay Accent Chest

...time-tested english or french dovetail construction, for years of problemfree use. plywood drawer bottoms are attached to plywood drawer...

3d_ocean

$19

Low Poly Cafe

...if you have any questions or if you have problem ...

3d_ocean

$5

Tiny Tiles 3 types

...colour – greens material can be scaled without any problem. help...

3d_ocean

$9

Low Poly ShotGun

...391 verts,2048×2048 diffuse & normal maps,if you feel any problem leave a...

3d_ocean

$15

Low Poly Micro Druid Lara

...lara! she can talk to animals and plants… the problem is… they can’t understand what she’s saying. she has...

3d_ocean

$8

Low Poly Tree Set

...matter which program you use there should be no problem using...